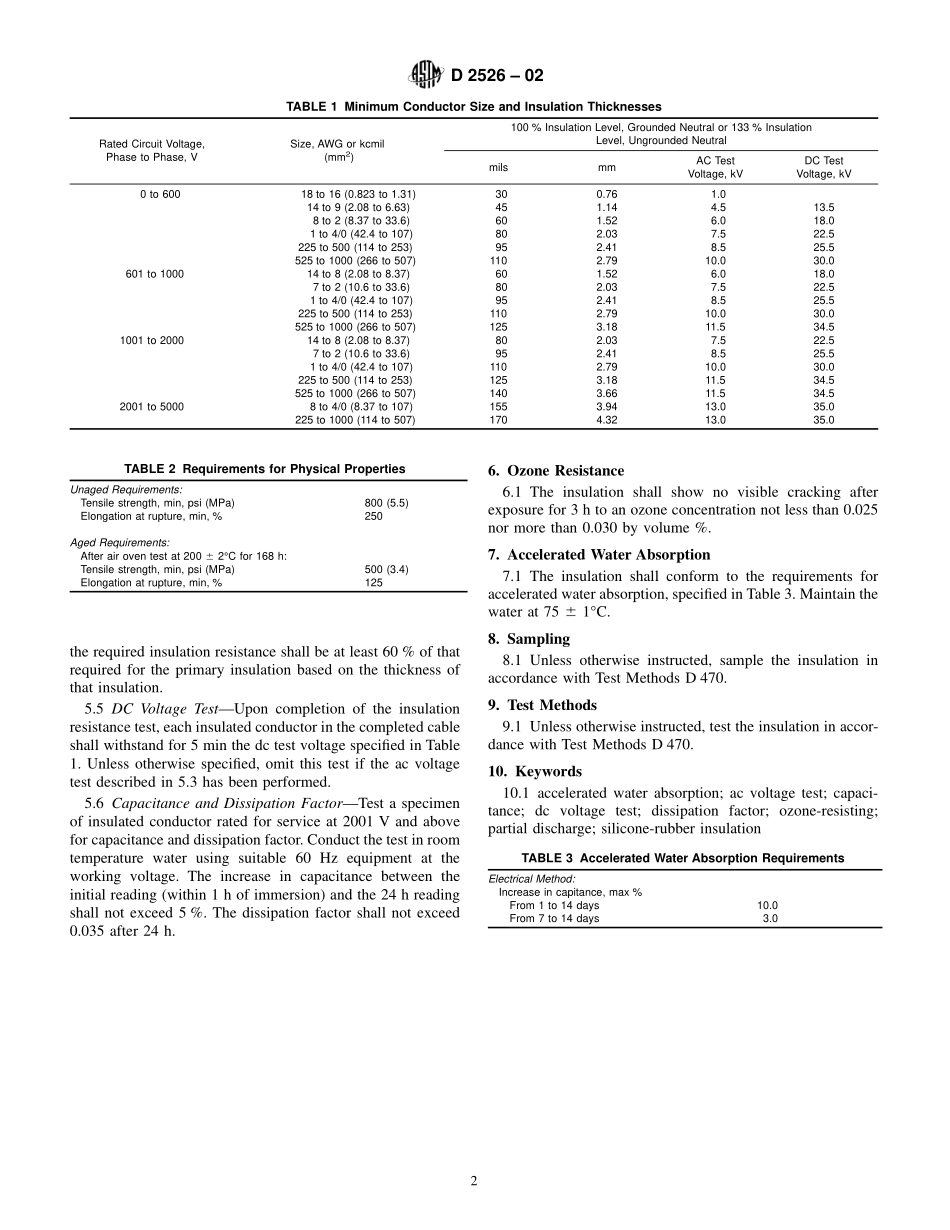

Designation:D2526–02AnAmericanNationalStandardStandardSpecificationforOzone-ResistingSiliconeRubberInsulationforWireandCable1ThisstandardisissuedunderthefixeddesignationD2526;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversanozone-resistingcrosslinkedsiliconerubberinsulatingcompoundforelectricalwiresandcables.1.2Thistypeofinsulationisconsideredsuitableforcon-tinuousoperationatconductortemperaturesupthrough125°Cforpowercableapplications.Itisconsideredsuitableforconductorsizesuptoandincluding1000kcmil(507mm2)atamaximumof5000Vforbothsingle-and-multiple-conductorcables.MinimumconductorsizesandinsulationthicknessesaregiveninTable1.1.3Whenevertwosetsofvaluesarepresented,indifferentunits,thevaluesinthefirstsetarethestandard,whilethoseinparenthesesareforinformationonly.1.4Inmanyinstancestheinsulationmaterialcannotbetestedunlessithasbeenformedaroundaconductororcable.Therefore,testsdoneoninsulatedwireorcableinthisdocumentaresolelytodeterminetherelevantpropertyoftheinsulationmaterialandnottotesttheinsulatedconductororcompletedcable.2.ReferencedDocuments2.1ASTMStandards:D470TestMethodsforCrosslinkedInsulationsandJacketsforWireandCable2D1711TerminologyRelatingtoElectricalInsulation22.2ICEAStandard:T-24-380GuideforPartial-DischargeProcedure33.Terminology3.1Definitions:Fordefinitionsoftermsusedinthisspeci-fication,refertoTerminologyD1711.3.2DefinitionofTermSpecifictoThisStandard:3.2.1aging(actof),n—exposureofmaterialtoairat20062°Cfor168h.4.PhysicalPropertiesRequirements4.1Thecrosslinkedinsulationshallconformtotherequire-mentsforphysicalpropertieslistedinTable2.5.ElectricalRequirements5.1OrderofTesting—Performthepartialdischarge,acvoltage,insulationresistance,anddcvoltagetestsinthatorderwhenanyofthesetestsarespecified.Thesequenceofothert...