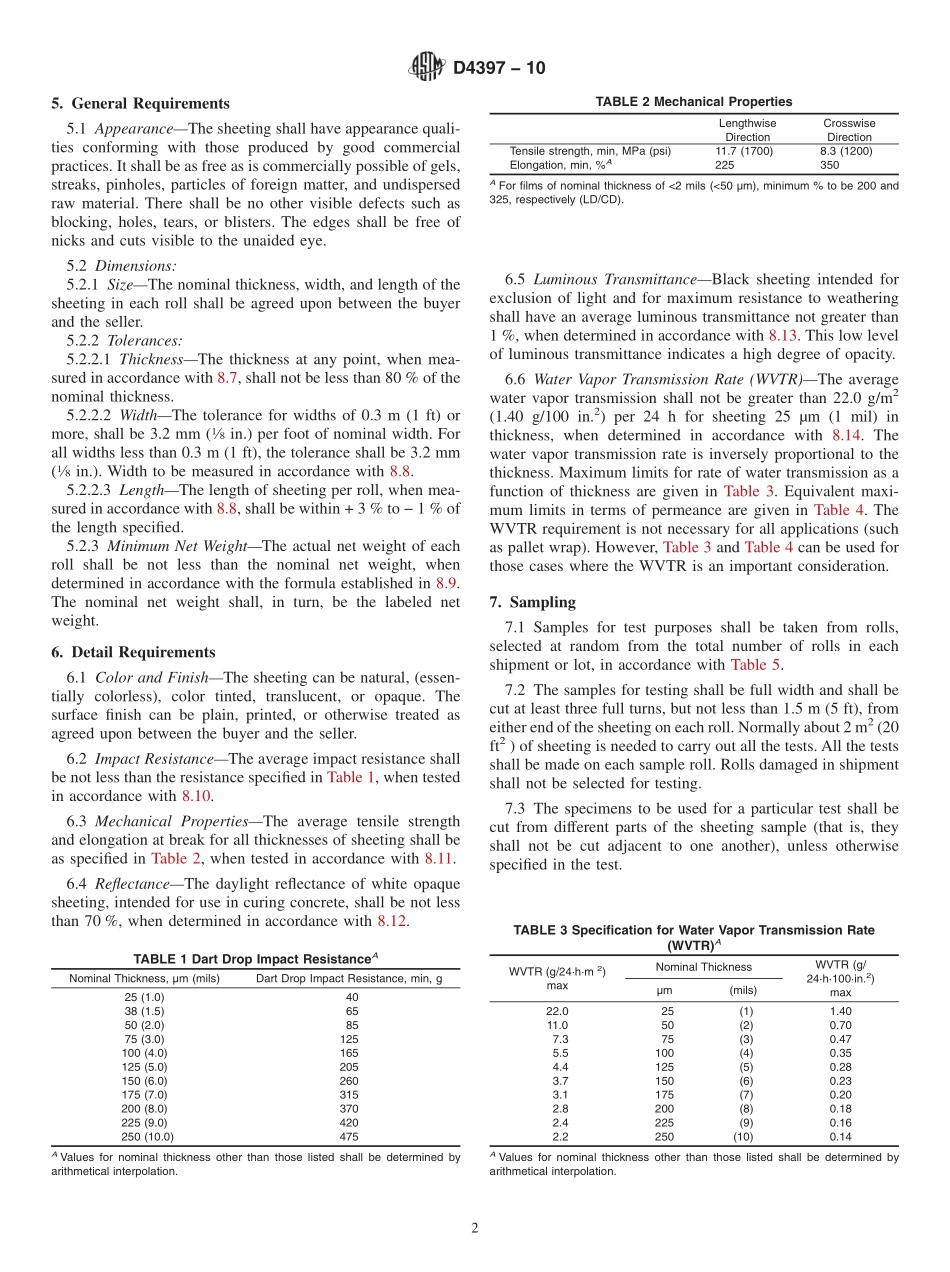

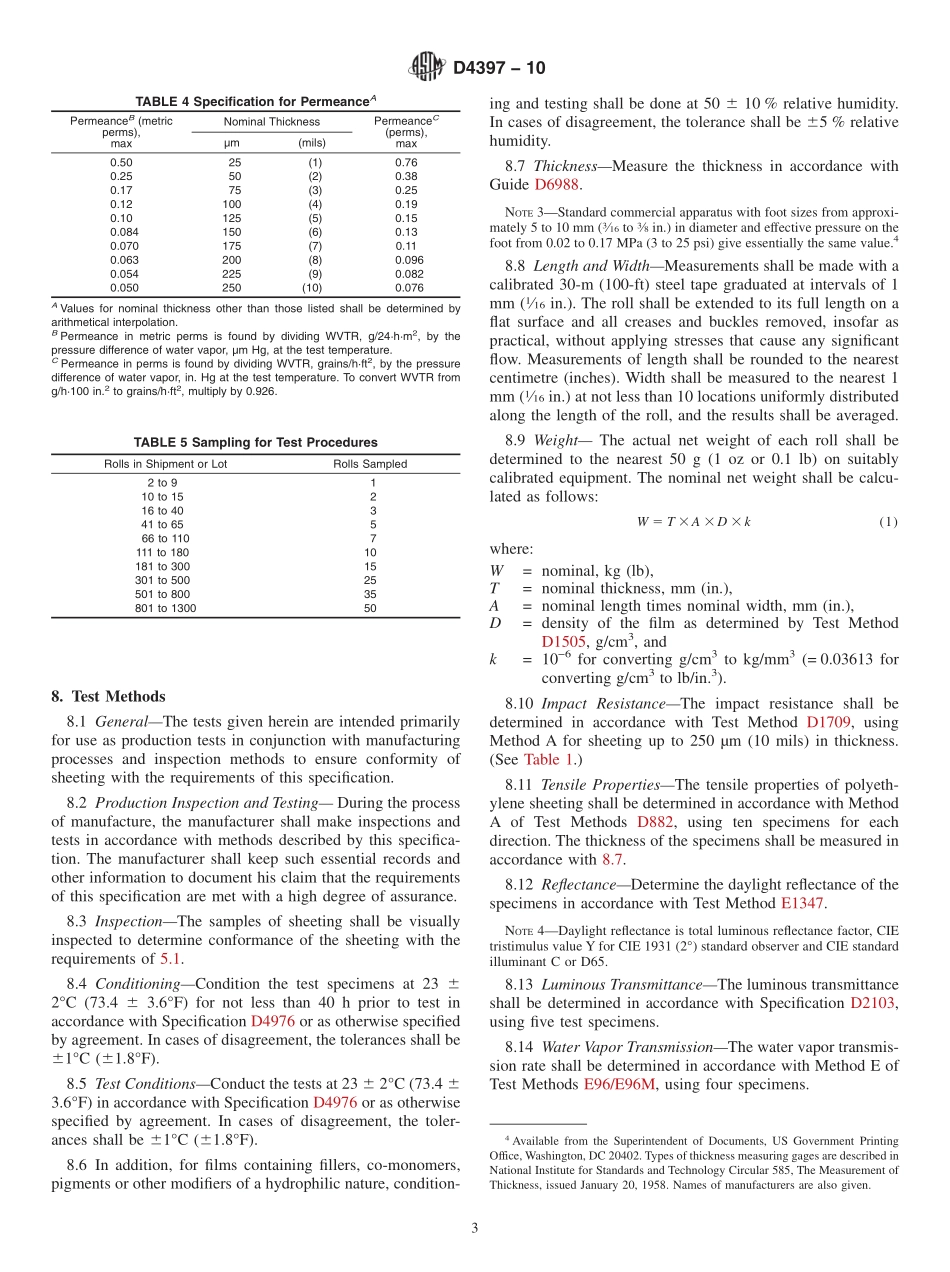

Designation:D4397−10StandardSpecificationforPolyethyleneSheetingforConstruction,Industrial,andAgriculturalApplications1ThisstandardisissuedunderthefixeddesignationD4397;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thisspecificationcoverspolyethylenesheeting,250µm(0.010in.or10mils)orlessinthickness,intendedforconstruction,industrial,andagriculturalapplications.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.1.3Thefollowingprecautionarystatementpertainsonlytothetestmethodsportion,Section8ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingD882TestMethodforTensilePropertiesofThinPlasticSheetingD883TerminologyRelatingtoPlasticsD1505TestMethodforDensityofPlasticsbytheDensity-GradientTechniqueD1709TestMethodsforImpactResistanceofPlasticFilmbytheFree-FallingDartMethodD2103SpecificationforPolyethyleneFilmandSheetingD3892PracticeforPackaging/PackingofPlasticsD4976SpecificationforPolyethylenePlasticsMoldingandExtrusionMaterialsD6988GuideforDeterminationofThicknessofPlasticFilmTestSpecimensE96/E96MTestMethodsforWaterVaporTransmissionofMaterialsE1347TestMethodforColorandColor-DifferenceMea-surementbyTristimulusColorimetryF88TestMethodforSealStrengthofFlexibleBarrierMaterials2.2MilitaryStandard:MIL-STD-1916DoDPreferredMethodsforAcceptanceofProduct33.Terminology3.1Definitions—Theplasticsterminologyusedinthisspeci-ficationisinaccordancewiththede...