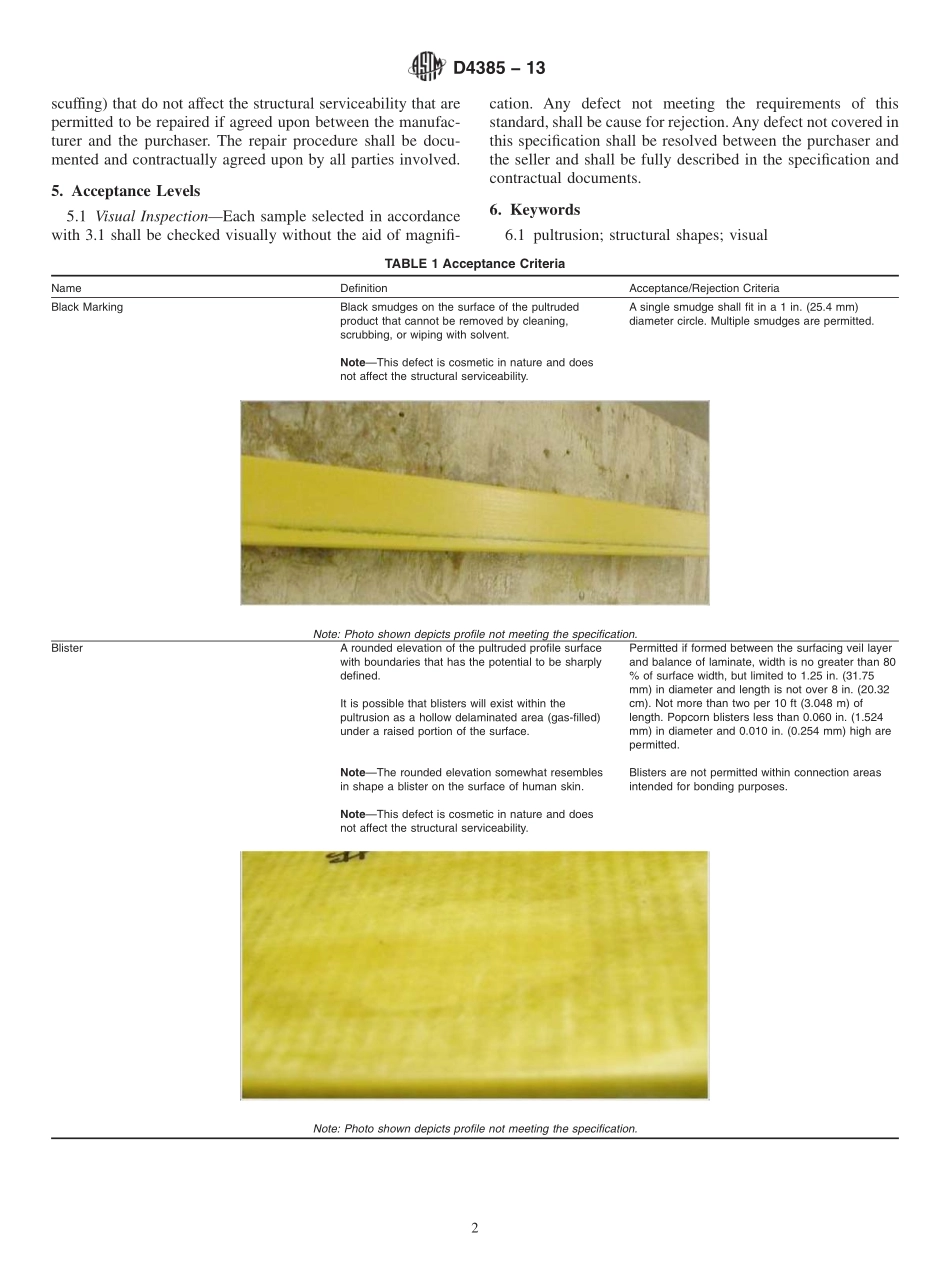

Designation:D4385−13StandardPracticeforClassifyingVisualDefectsinThermosettingReinforcedPlasticPultrudedProducts1ThisstandardisissuedunderthefixeddesignationD4385;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thispracticecoversacceptancecriteriaforvisualac-ceptanceofthermosettingreinforcedplasticpultrudedrods,bars,shapes,andsheets.1.2Thispracticepresentsdefinitionsofpossibledefectstoserveasaguideforcontracts,drawings,productspecifications,andfinalinspection.1.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:2D3917SpecificationforDimensionalToleranceofThermo-settingGlass-ReinforcedPlasticPultrudedShapes3.Terminology3.1matdiscoloration—ayellowingofthereinforcingmatscausedbybindermigration.Thediscolorationcancausevisualstreaksonthesurfaceofthepultrusion.3.2testrequirement—minimumdesign,characteristicorspecifiedvaluesasdictatedandorspecifiedbycodes,standards,industry,endcustomers,themanufacturerortheEngineerofRecord.3.3connectionareas—areasassociatedwithapultrudedmemberthatformaconnectioninsomeformorfashionthatwillnotbevisibleafterfabrication.3.4fiberblooming—exposedreinforcementsonthesurfaceofaprofileasaresultofveilslippageorlackofresin.Suchdefectscancausetheexposedfiberto“bloom”whenexposedtoultravioletlight.3.5internallayer—referstoindividuallayersofunidirec-tionalortransversereinforcem...