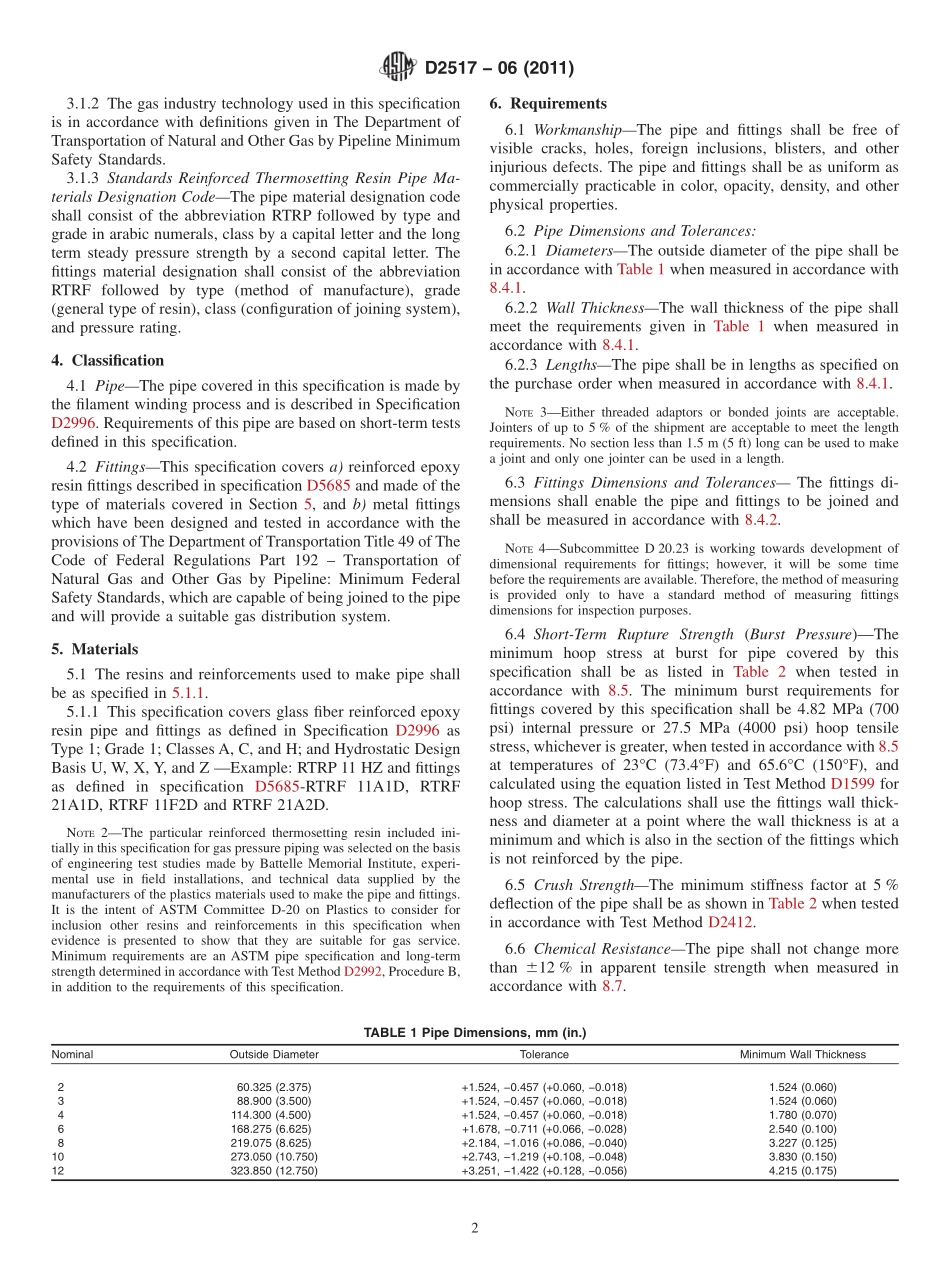

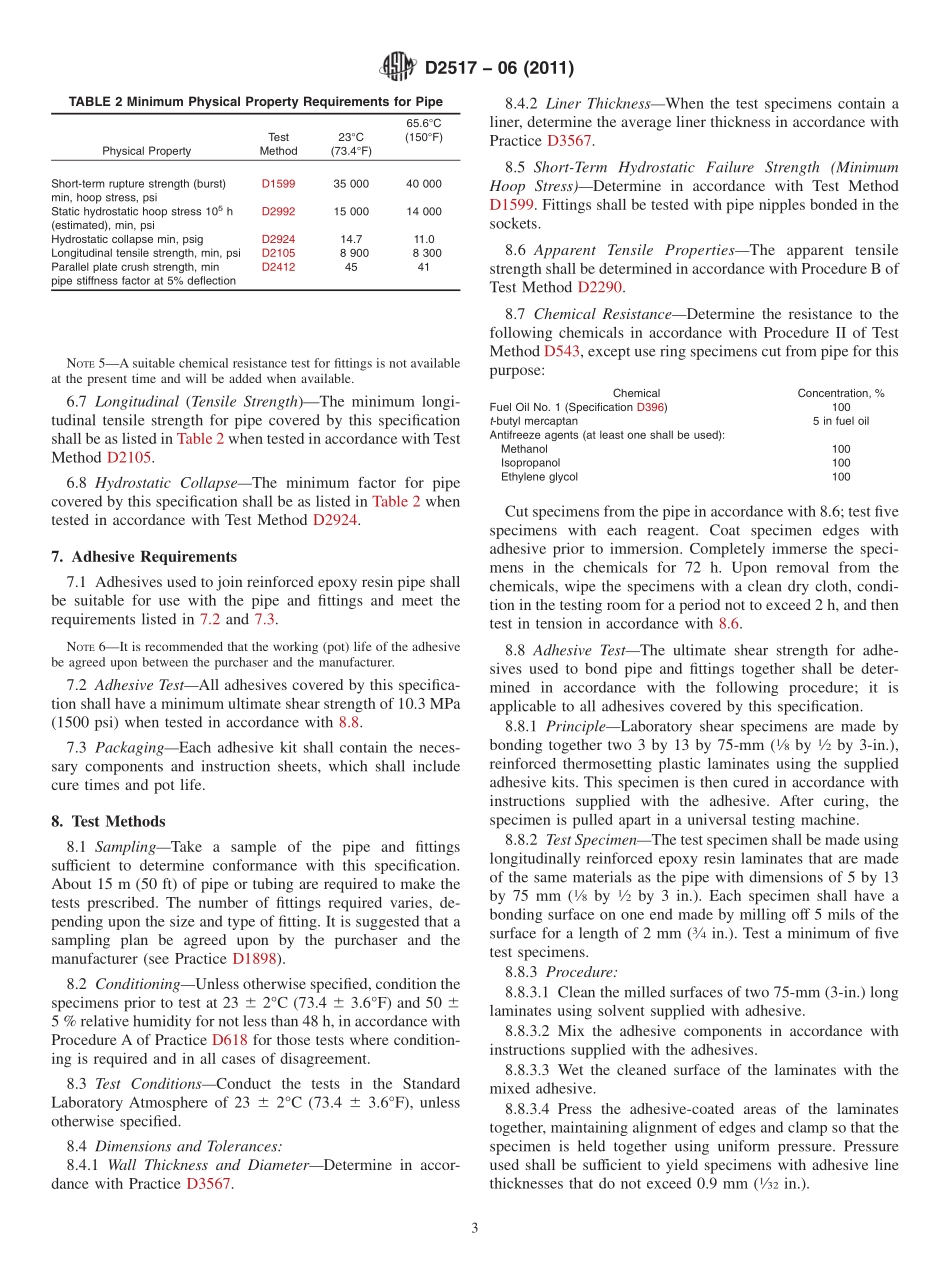

Designation:D2517−06(Reapproved2011)AnAmericanNationalStandardStandardSpecificationforReinforcedEpoxyResinGasPressurePipeandFittings1ThisstandardisissuedunderthefixeddesignationD2517;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope*1.1Thisspecificationcoversrequirementsandmethodsoftestformaterials,dimensionsandtolerances,hydrostatic-burststrength,chemicalresistance,andlongitudinaltensileproperties,forreinforcedepoxyresinpipeandfittingsforuseingasmainsandservicesfordirectburialandinsertionapplications.Thepipeandfittingscoveredbythisspecificationareintendedforuseinthedistributionofnaturalgas,petro-leumfuels(propane–airandpropane–butanevapormixtures),manufacturedandmixedgaseswhereresistancetogaspermeation,toughness,resistancetocorrosion,aging,anddeteriorationfromwater,gas,andgasadditivesarerequired.Methodsofmarkingarealsogiven.DesignconsiderationsarediscussedinAppendixX1.1.2ThevaluesinSIunitsaretoberegardedasthestandard.1.3Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodportion,Section8,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.1.4ArecommendedinplantqualitycontrolprogramisgiveninAppendixX2.2.ReferencedDocuments2.1ASTMStandards:2D396SpecificationforFuelOilsD543PracticesforEvaluatingtheResistanceofPlasticstoChemicalReagentsD618PracticeforConditioningPlasticsforTestingD883TerminologyRelatingtoPlasticsD1598TestMethodforTime-to-FailureofPlasticPipeUnderConstantInternalPressureD1599TestMethodforResistancetoShort-TimeHydr...