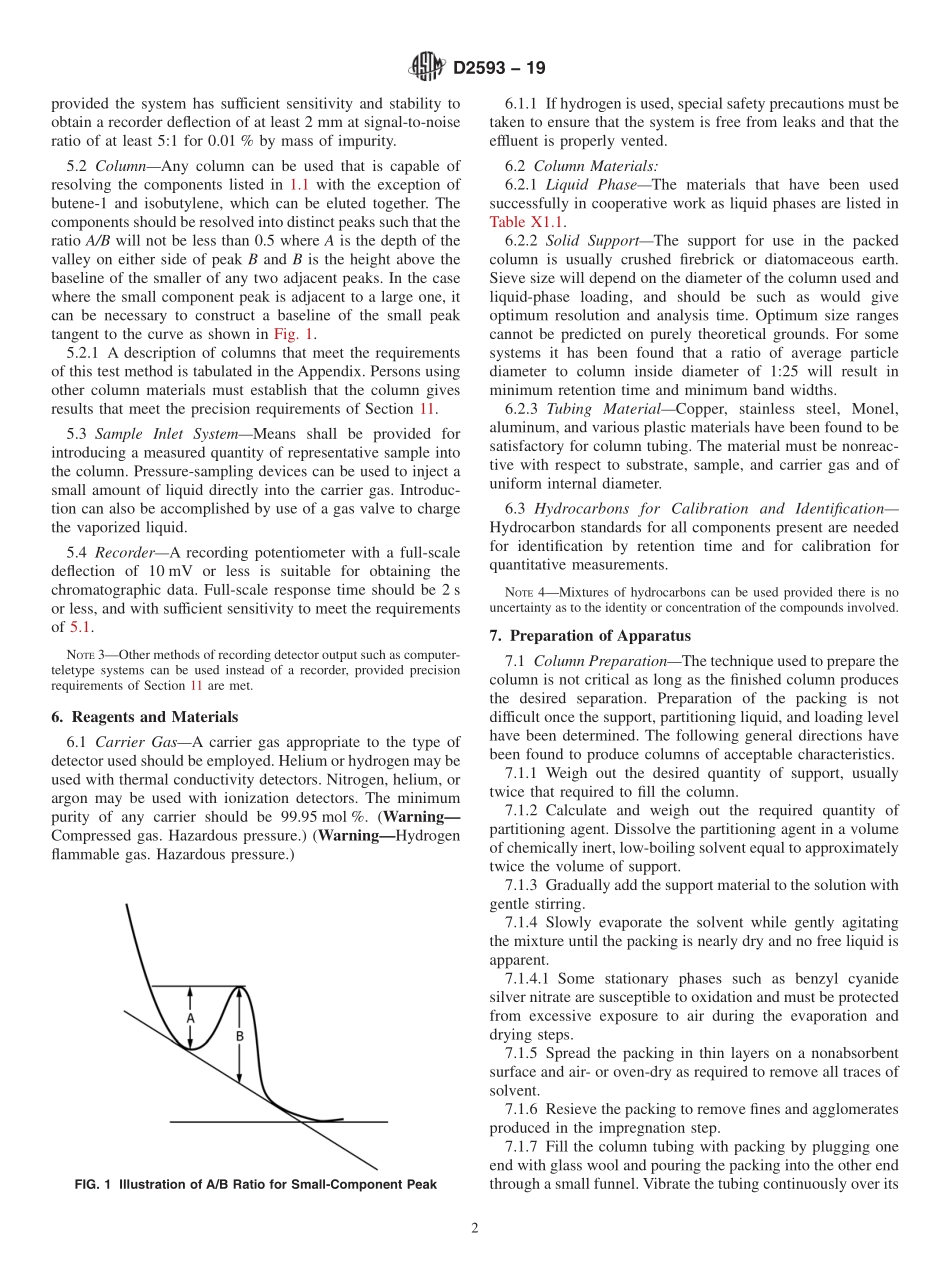

Designation:D2593−19StandardTestMethodforButadienePurityandHydrocarbonImpuritiesbyGasChromatography1ThisstandardisissuedunderthefixeddesignationD2593;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversthedeterminationofbutadiene-1,3purityandimpuritiessuchaspropane,propylene,isobutane,n-butane,butene-1,isobutylene,propadiene,trans-butene-2,cis-butene-2,butadiene-1,2,pentadiene-1,4,and,methyl,dimethyl,ethyl,andvinylacetyleneinpolymerizationgradebutadienebygaschromatography.Impuritiesincludingbutadienedimer,carbonyls,inhibitor,andresiduearemeasuredbyappropriateASTMproceduresandtheresultsusedtonormalizethecomponentdistributionobtainedbychromatog-raphy.NOTE1—Otherimpuritiespresentincommercialbutadienemustbecalibratedandanalyzed.Otherimpuritieswerenottestedinthecoopera-tiveworkonthistestmethod.NOTE2—Thistestmethodcanbeusedtocheckforpentadiene-1,4andotherC5sinsteadofTestMethodD1088.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.Forspecificwarningstatements,see6.1and9.3.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D1088MethodofTestforBoilingPointRangeofPolymerization-GradeButadiene(Withdrawn1983)32.2EnergyInstituteStandards:4IP194AnalysisofButadiene-1,3P...