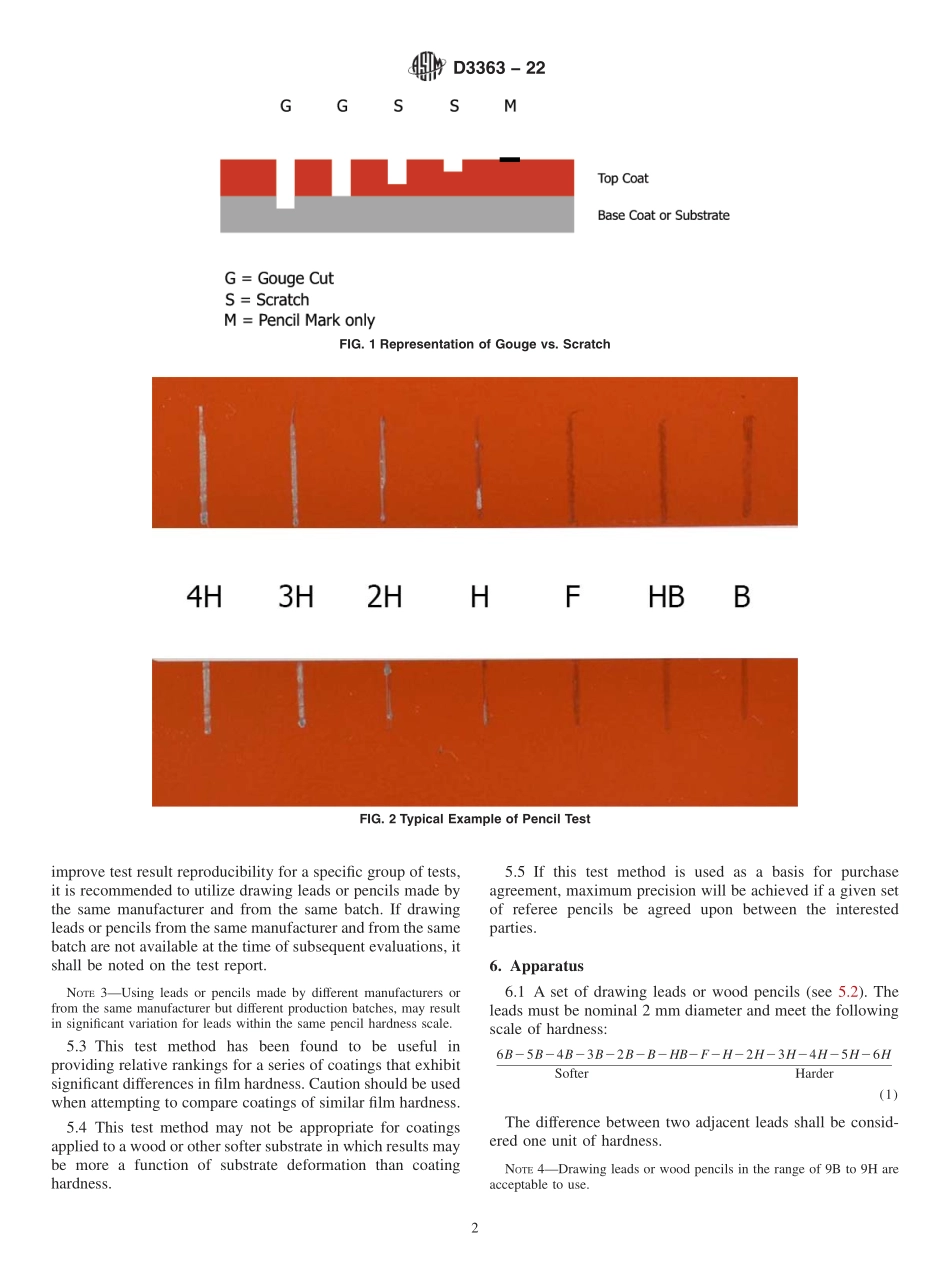

Designation:D3363−22StandardTestMethodforFilmHardnessbyPencilTest1ThisstandardisissuedunderthefixeddesignationD3363;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thistestmethodcoversaprocedureforrapid,inexpen-sivedeterminationofthefilmhardnessofanorganiccoatingonametalorsimilarlyhardsubstrateintermsofdrawingleadsorpencilleadsofknownhardness.1.2Thistestmethodissimilarincontent(butnottechni-callyequivalent)toISO15184.NOTE1—Otherproceduresareavailabletomeasurepermanentdefor-mationoforganiccoatingsundertheactionofasinglepoint(stylustip)includingbutnotlimitedtoTestMethodsD2197,D5178,andG171.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D2197TestMethodforAdhesionofOrganicCoatingsbyScrapeAdhesionD5178TestMethodforMarResistanceofOrganicCoatingsG171TestMethodforScratchHardnessofMaterialsUsingaDiamondStylus2.2OtherStandards:ISO15184Determinationoffilmhardnessbypenciltest33.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1gougehardness,n—thehardestpencilleadthatwillleavethefilmuncutforastrokelengthofatleast3mm(1⁄8in.);alsoreferredtoaspencilhar...