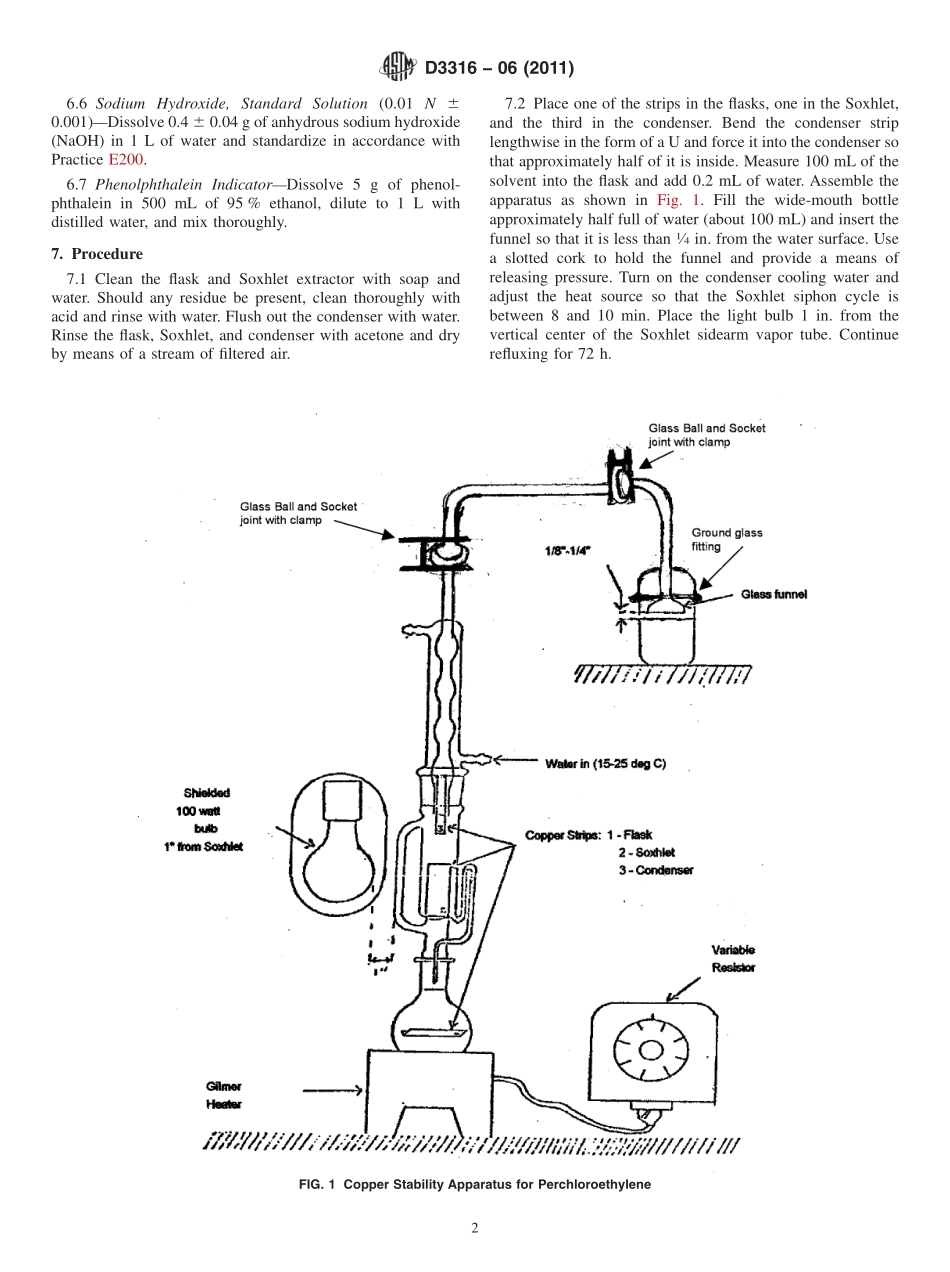

Designation:D3316−06(Reapproved2011)StandardTestMethodforStabilityofPerchloroethylenewithCopper1ThisstandardisissuedunderthefixeddesignationD3316;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoverstheevaluationofthecorrosive-nesstocoppermetalbyperchloroethylene.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E200PracticeforPreparation,Standardization,andStorageofStandardandReagentSolutionsforChemicalAnalysis3.SummaryofTestMethod3.1Cleancopperstripsaresubjectedtotheactionofliquidandvaporphasesofboilingperchloroethylenefor72hinthepresenceoflight.Weightlossofcopperstripsandacidformationaredeterminedattheendofthetestperiod.4.SignificanceandUse4.1Thistestmethodistobeusedasaguideinselectingoreliminatingcertaingradesofperchloroethyleneusedfordry-cleaningfabricsordegreasingmetalparts.5.Apparatus5.1Flask,300-mL,24/40standard-taperjoint.5.2SoxhletExtractor,30-mminsidediameter,24/40standard-taperbottomjoint,34/45standard-taperupperjoint.5.3AllihnCondenser,bulbtype,34/45standard-taperbot-tomjoint.5.4Bottle,wide-mouth,8oz.5.5Funnel,8-mmoutsidediameterstem,35-mmdiameteropening.5.6Heater,variablecontrol.5.7LightBulb,100W.5.8Beaker,400mL.5.9AnalyticalBalance.6.ReagentsandMaterials6.1PurityofReagents—Reagentgradechemicalsshallbeusedinalltests.Unlessotherwiseindicated,itisintendedthatallreagentsshallconformtothespecificationsoftheCommit-teeonAnalyticalReagentsoftheAmericanChemicalSociety,wheresuchspecificationsareava...