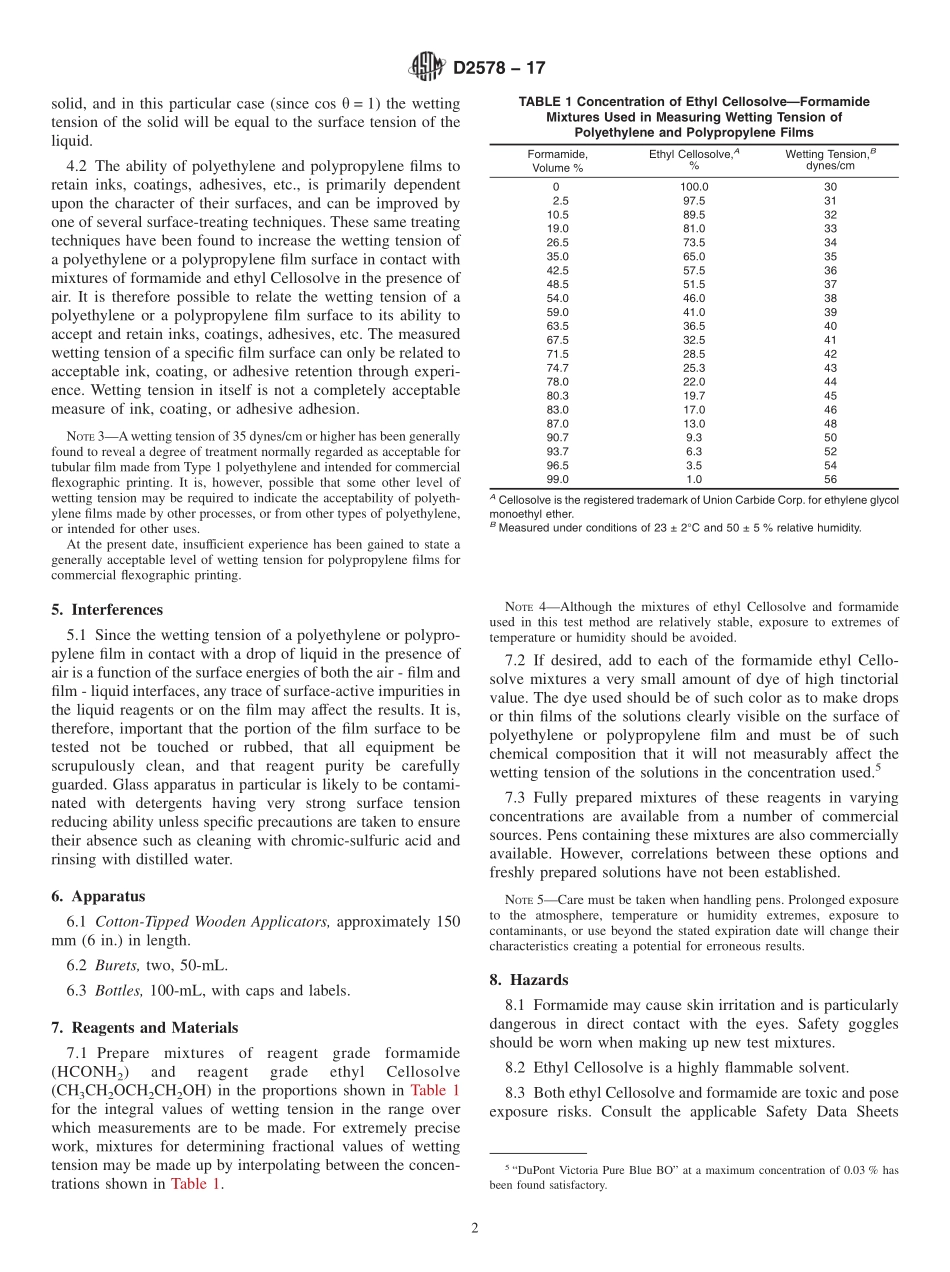

Designation:D2578−17StandardTestMethodforWettingTensionofPolyethyleneandPolypropyleneFilms1ThisstandardisissuedunderthefixeddesignationD2578;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversthemeasurementofthewettingtensionofapolyethyleneorpolypropylenefilmsurfaceincontactwithdropsofspecifictestsolutionsinthepresenceofair.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesaremathematicalconversionstoinch-poundunitsthatareprovidedforinforma-tiononlyandarenotconsideredstandard.NOTE1—Thistestmethodandthespecifiedreagentswerespecificallydevelopedforpolyethyleneandpolypropylenefilms.Itispossibletoutilizethistestmethodandthespecifiedreagentsforfilmscomposedofotherpolymers,butthiscanaffectthesurfaceenergiesofthegas-liquidandsolid-liquidinterfaces,whichwillaffectthecontactangleandwettingtension.Theapplicabilityandsignificanceforuseofnon-polyolefinmaterialsmustbeestablishedbytheuser.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.SpecifichazardsstatementsaregiveninSection8.NOTE2—ThistestmethodisequivalenttoISO8296.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod2.2ISOStandard:ISO8296Plastics—FilmandSheet...