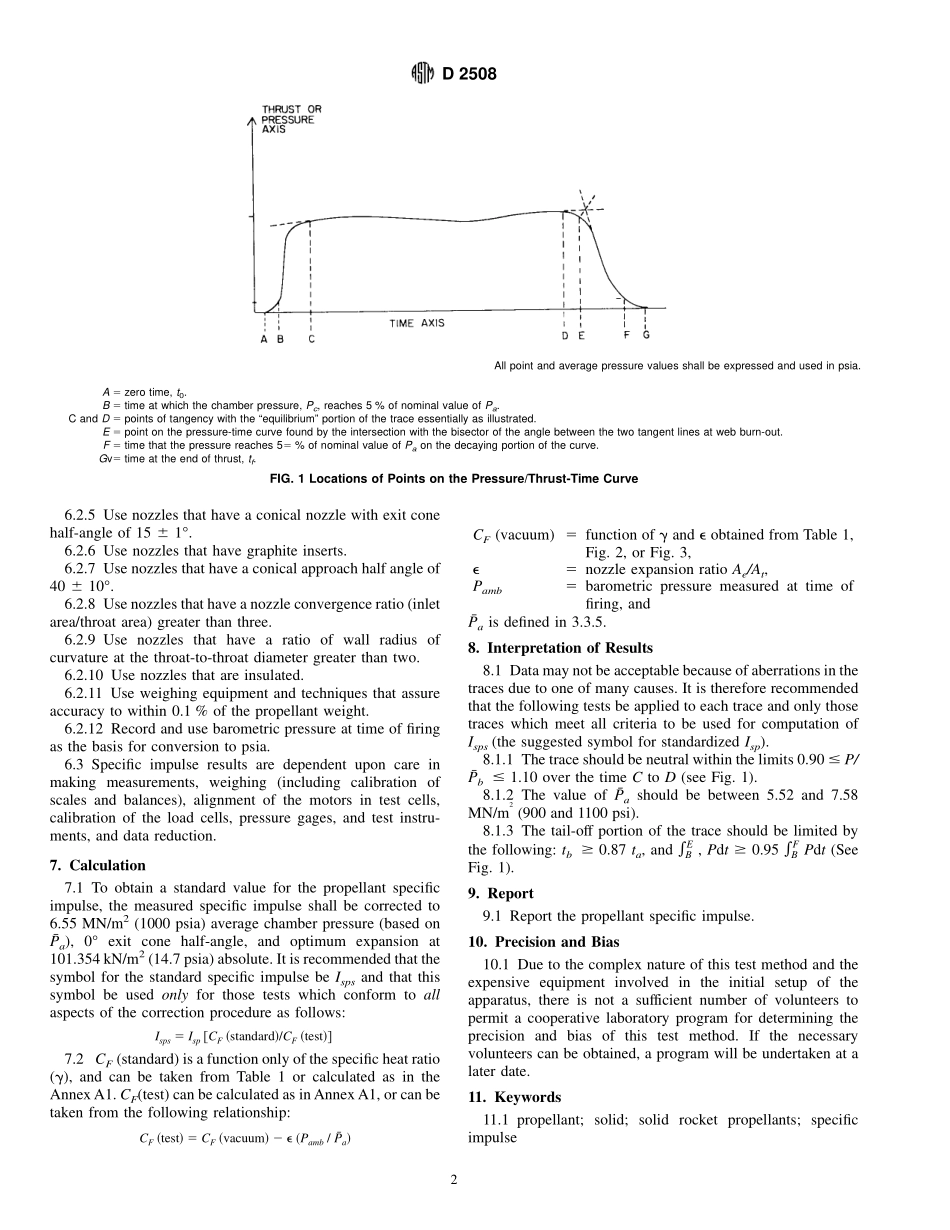

Designation:D2508–93AnAmericanNationalStandardStandardTestMethodforSolidRocketPropellantSpecificImpulseMeasurements1ThisstandardisissuedunderthefixeddesignationD2508;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthemeasurementofsolidpropellantspecificimpulsevalues.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.2.ReferencedDocuments2.1ASTMStandards:D2506TerminologyRelatingtoSolidRocketPropulsion22.2MilitarySpecification:MIL-STD-292C33.Terminology3.1Definitions—RefertoTerminologyD2506orMilitarySpecificationMIL-STD-292C.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1massofpropellant,m—p,tobeusedinthecalculationofspecificimpulse,shallbethemassofpropellantchargedintothemotor.3.2.1.1Anignitercorrectionshallbemade,determinedeitherbyexperimentorcalculation,whenthetheoreticalvalueofthiscorrectionexceeds0.1%.3.2.1.2Thedifferencebetweenbeforeandafterfiringweightsshallberecordedasexpendedweight.3.2.1.3Thepercentagedifferencebetweenexpendedweightandpropellantweightshallberecordedaseitherinertsexpended(iftheexpendedweightishigher)orresiduere-tained.Valueslessthan0.2%maybeignored.3.3Symbols:3.3.1totalimpulse—I5*AGFdt.3.3.2burningtime—tb5timefrom“B”to“E”.3.3.3actiontime—ta5timefrom“B”to“F”.3.3.4averagepressureoverburningtime—P¯b5*BEPdt/tb.3.3.5averagepressureoveractiontime—P¯a5*BEPdt/ta.3.3.6measuredspecificimpulse—Isp5I/mp,whichiscorrectedtostandardconditionsinaccordancewithSection8.4.SummaryofTestMethod4.1Thistestmethodsetsforththefollowing:4.1.1Asetofuniformdesignationstobeusedforthecalculations.4.1.2Precautionstobetakeninexperimentaltechniques.4.1.3Acceptablerangesofexperimentalconditionstoas-suregoodresults.4.1.4Uniformproceduresforcorrectingmeasuredvaluestoast...