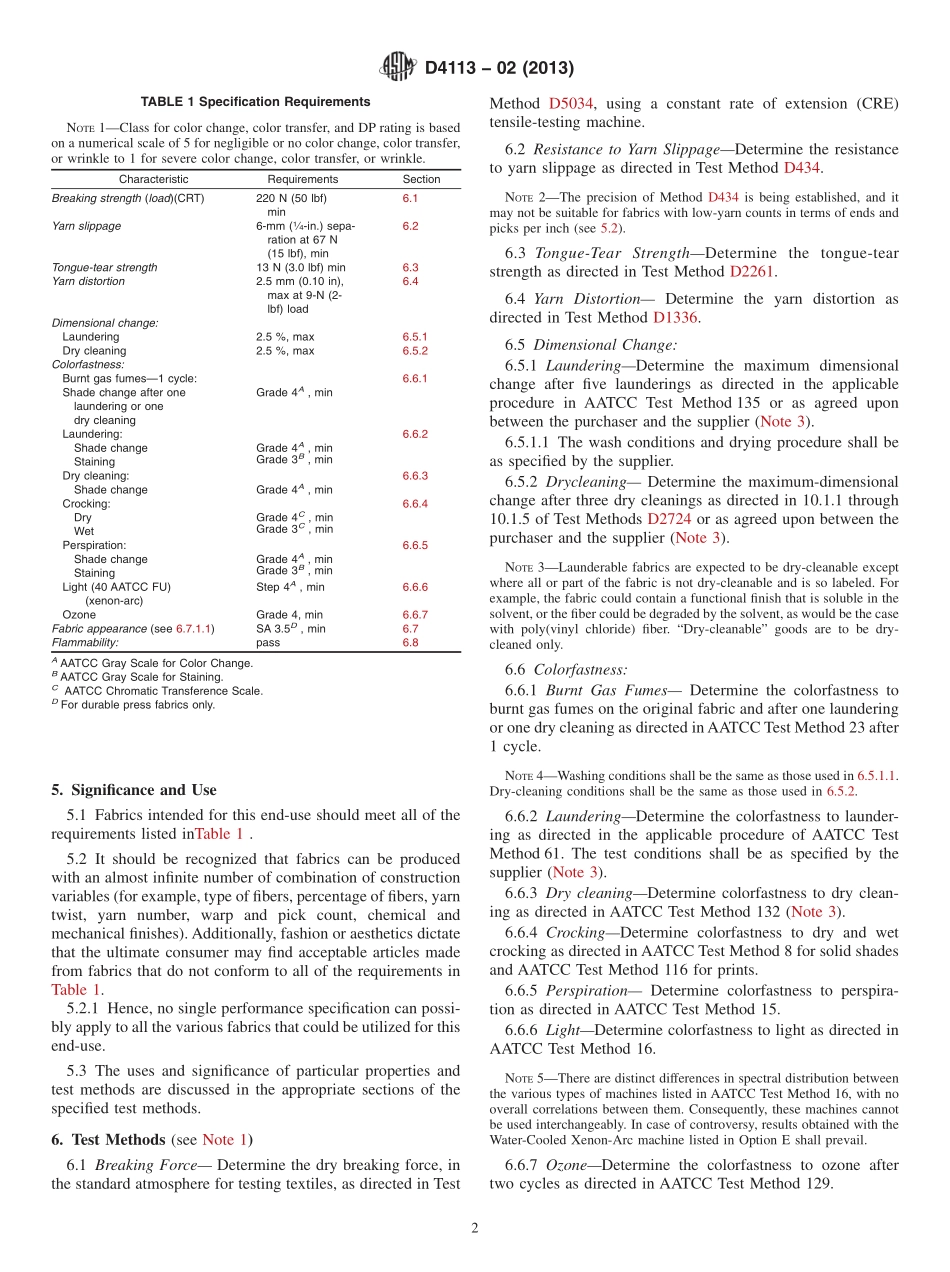

Designation:D4113−02(Reapproved2013)StandardPerformanceSpecificationforWovenSlipcoverFabrics1ThisstandardisissuedunderthefixeddesignationD4113;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisperformancespecificationcoverswovenfabricscomprisedofanytextilefiberormixtureoffiberstobeusedinslipcovers.1.2Theserequirementsapplytoboththelengthandwidthdirectionsforthosepropertieswherefabricdirectionisperti-nent.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D123TerminologyRelatingtoTextilesD434TestMethodforResistancetoSlippageofYarnsinWovenFabricsUsingaStandardSeam(Withdrawn2003)3D1336TestMethodforDistortionofYarninWovenFabricsD2261TestMethodforTearingStrengthofFabricsbytheTongue(SingleRip)Procedure(Constant-Rate-of-ExtensionTensileTestingMachine)D2724TestMethodsforBonded,Fused,andLaminatedApparelFabricsD5034TestMethodforBreakingStrengthandElongationofTextileFabrics(GrabTest)2.2AATCCTestMethods:48ColorfastnesstoCrocking:AATCCCrockmeterMethod15ColorfastnesstoPerspiration16ColorfastnesstoLight23ColorfastnesstoBurntGasFumes61ColorfastnesstoLaundering,HomeandCommercial:Accelerated116ColorfastnesstoCrocking:RotaryVerticalCrockmeterMethod124AppearanceofFabricsAfterRepeatedHomeLaunder-ings129ColorfastnesstoOzoneintheAtmosphereUnderHighHumidities132ColorfastnesstoDrycleaning135DimensionalChangesinAutomaticHomeLaunderingofWovenorKnitFabrics187DimensionalChangesofFabrics:AcceleratedEvaluationProcedureNo.1GrayScaleforColorChangeEvaluationProcedureNo.2GrayScaleforStainingEvaluationProcedureNo.8AATCC9–StepChromaticTransferenceScale2.3...