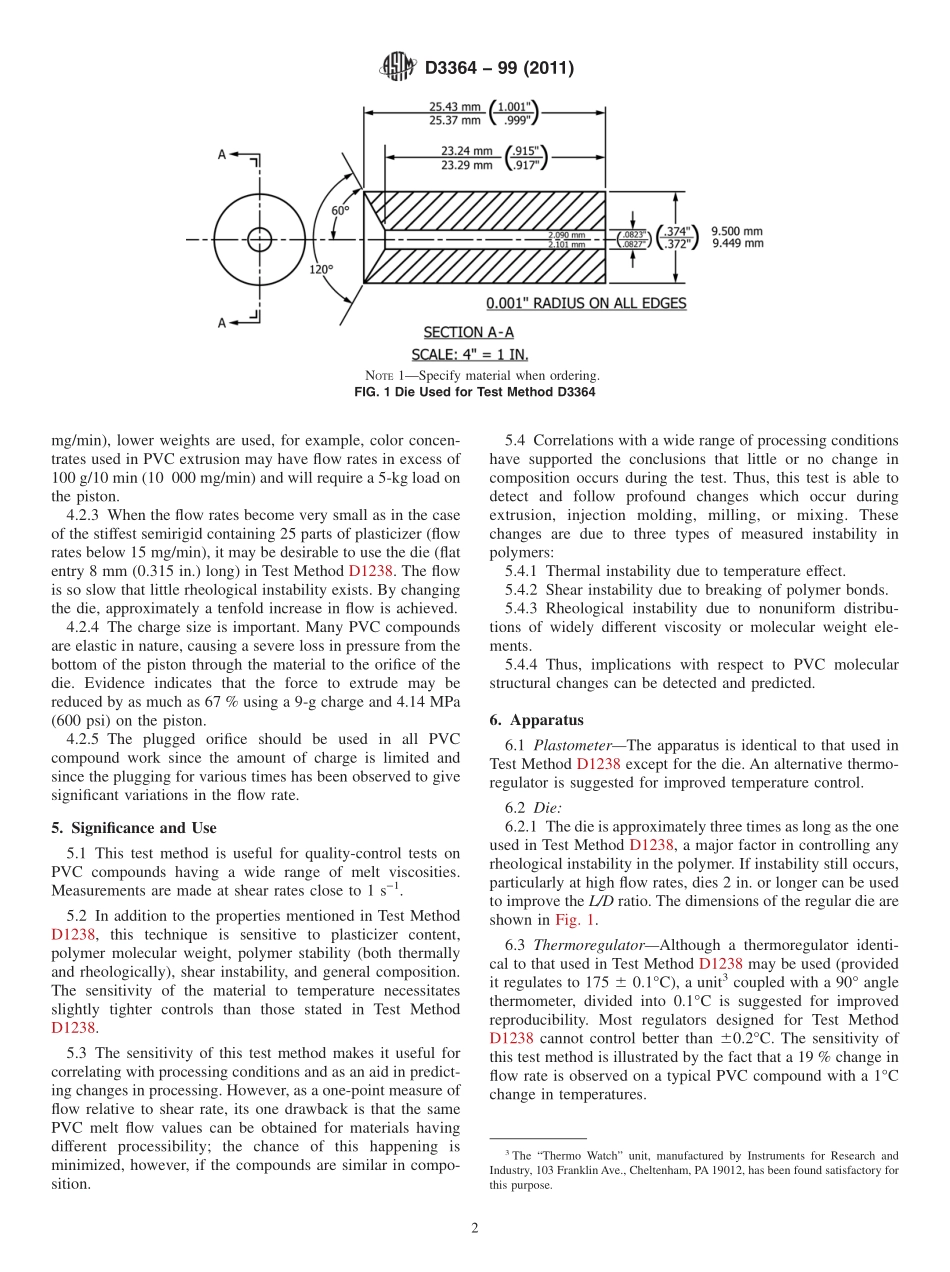

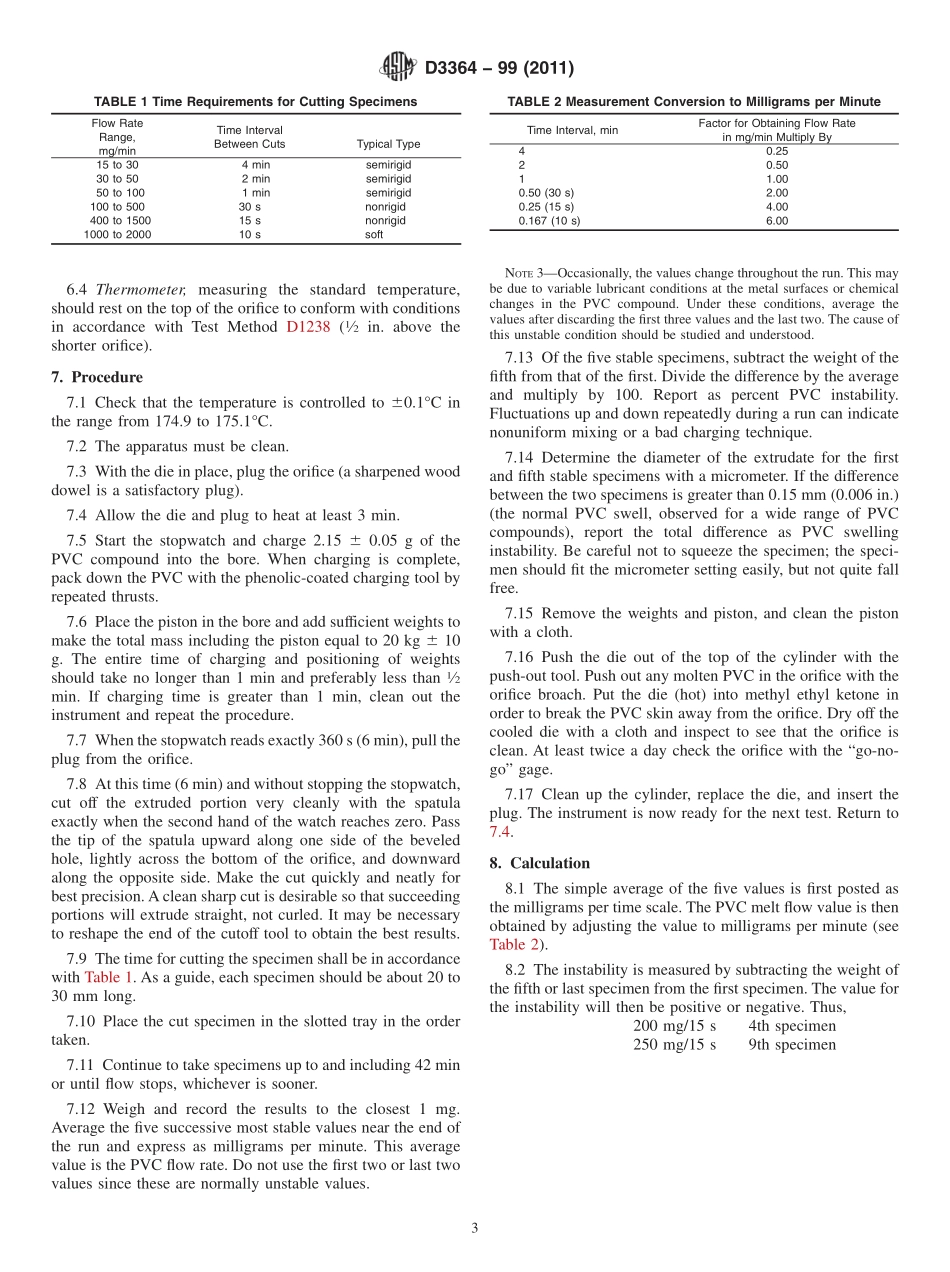

Designation:D3364−99(Reapproved2011)StandardTestMethodforFlowRatesforPoly(VinylChloride)withMolecularStructuralImplications1ThisstandardisissuedunderthefixeddesignationD3364;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThistestmethodisanextensionofTestMethodD1238specifictothemeasurementofflowratesofpoly(vinylchloride)(PVC)compoundswhiledetectingandcontrollingvariouspolymerinstabilitiesassociatedwiththeflowrate.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesaremathematicalconversionstoinch-poundunitsthatareprovidedforinforma-tiononlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:2D883TerminologyRelatingtoPlasticsD1238TestMethodforMeltFlowRatesofThermoplasticsbyExtrusionPlastometerD3835TestMethodforDeterminationofPropertiesofPolymericMaterialsbyMeansofaCapillaryRheometerE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions—Fordefinitionsrelatedtoplastics,seeTer-minologyD883.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1SeeTestMethodD3835,Sections5.1,5.2,and5.3.3.2.2Flowisthereciprocaloftheviscosity;therefore,theflowisdefinedasthevolumetricdisplacementthroughacontrolledorificeandisexpressedasshearrateovershearstress.NOTE2—SincePVCobeysthepowerlawfunction,theaboverelation-shipcanbeexpressedasfollows:(Viscosity)(ShearRate)1−N=(shearstress)inwhichtheshearrateisexpressedas4Q/πR3anddependsonth...