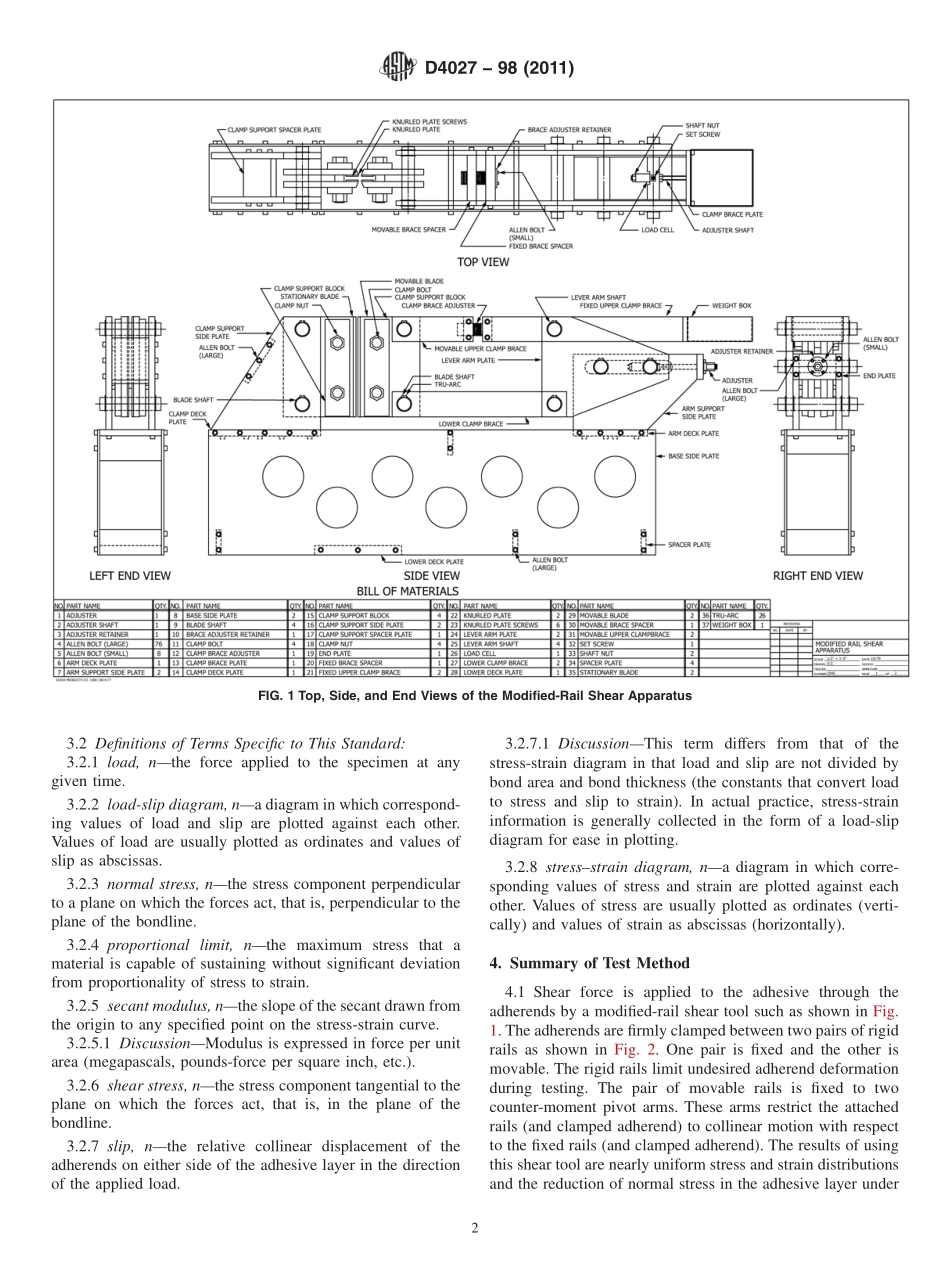

Designation:D4027−98(Reapproved2011)StandardTestMethodforMeasuringShearPropertiesofStructuralAdhesivesbytheModified-RailTest1ThisstandardisissuedunderthefixeddesignationD4027;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribesequipmentandprocedurestomeasuretheshearmodulusandshearstrengthofadhesivelayersbetweenrigidadherends.Theequipmentmayalsobeusedfordeterminingtheadhesive’sshearcreepcompliance,theeffectsofstrainhistorysuchascyclicloadinguponshearproperties,andafailurecriteriaforbiaxialstressconditionssuchasshearplustensionandshearpluscompression.21.2High-densitywoodshallbethepreferredsubstrate.Thepracticalupperlimitontheshearmodulusthatcanbemeasuredisdeterminedbytheshearmodulusoftheadherendsandbythestrainmeasuringdevice.Thus,thepracticallimitofadhesiveshearmodulusthatcanbemeasuredusinghigh-densitywoodadherendsisabout690MPa(1×105psi).NOTE1—Wood-basecomposites,metal,plastic,reinforcedplastics,andothercommonconstructionmaterialsmayalsobeusedforadherends.1.3Therangeofspecimendimensionsthatcanbetestedare:width1.59to12.70mm(0.0625to0.500in.),length102to203mm(4to8in.),andadherendthickness13to25mm(0.50to1.00in.).Thestandardspecimendimensionsshallbe:width3.18mm(0.125in.),length203mm(8in.),andadherendthickness19mm(0.75in.).Bondlinethicknessesfrom0.15to3.18mm(0.006to0.125in.)maybetested.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3D905TestMethodforStrengthPropertiesofAdhesiveBondsinShearbyCompressio...