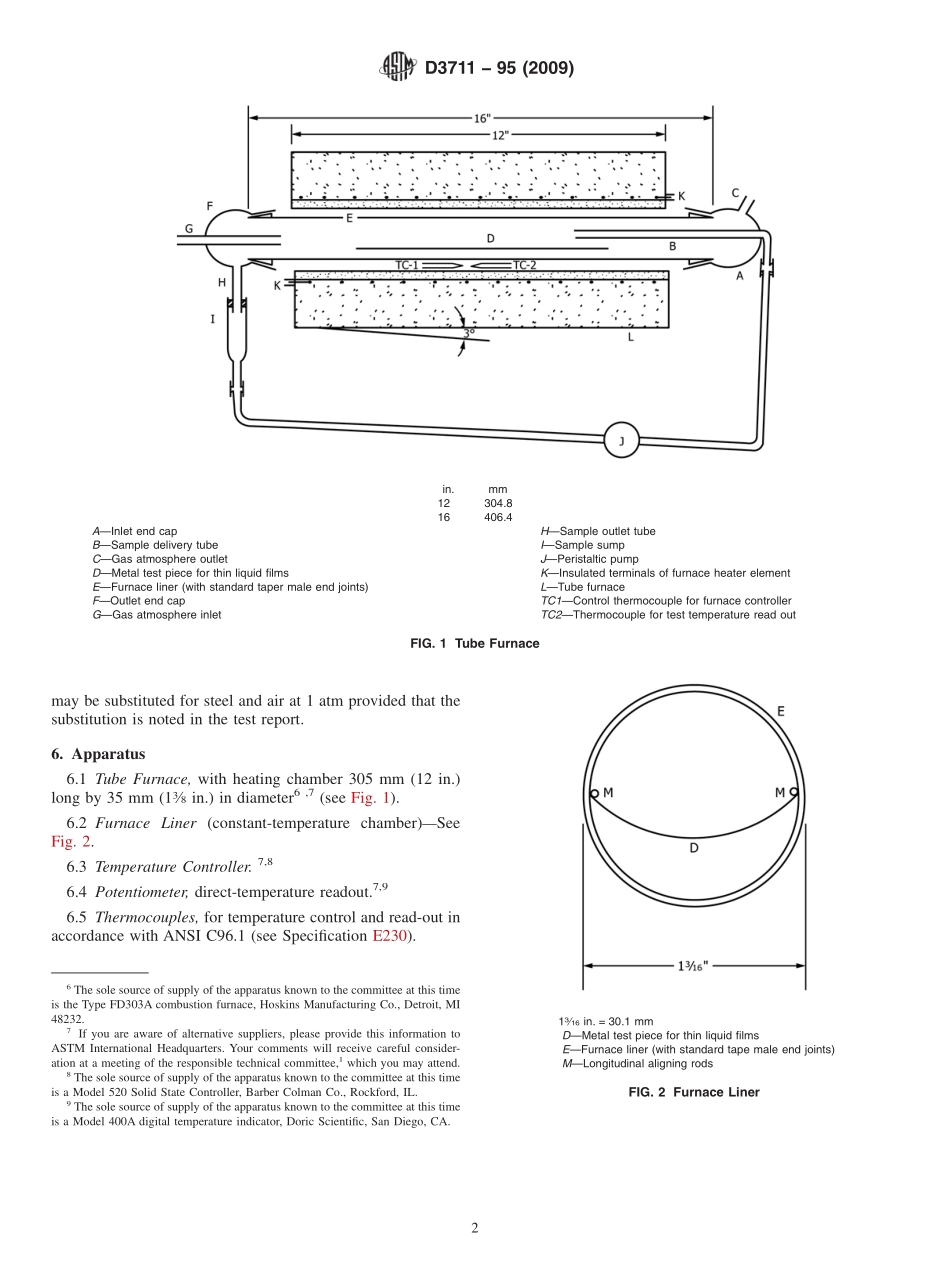

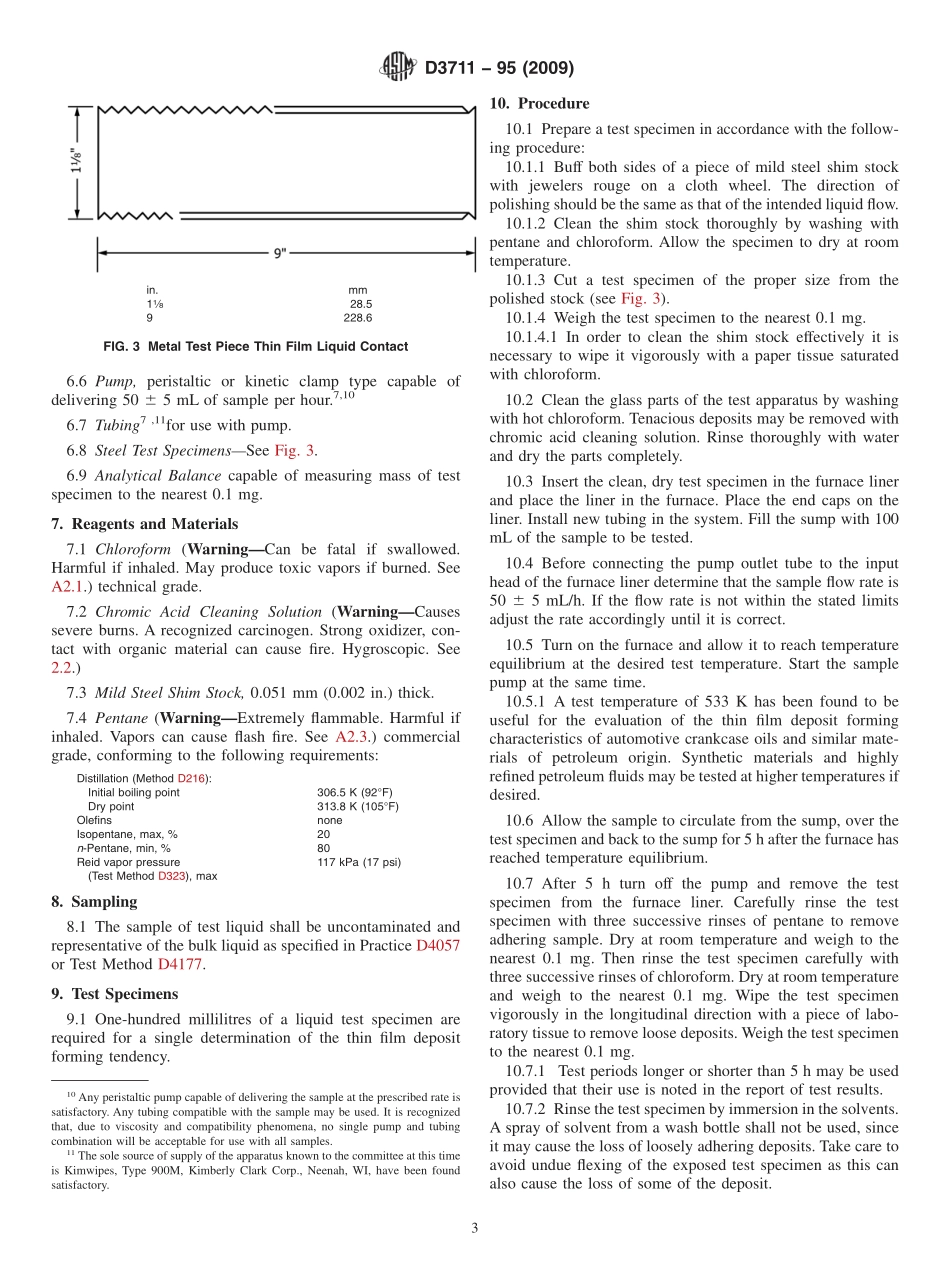

Designation:D3711−95(Reapproved2009)StandardTestMethodforDepositionTendenciesofLiquidsinThinFilmsandVapors1ThisstandardisissuedunderthefixeddesignationD3711;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftheten-dencyofliquidsinthinfilmsandofvaporstoformdepositsonmetalsurfaces.Thetestmethodappliestobothpetroleum-basedandsyntheticlubricants,hydraulicfluids,heat-transferfluids,andrelatedmaterials.21.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Incaseswherematerials,products,orequipmentareavailableininch-poundunitsonly,SIunitsareomitted.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Forspecificwarningstatements,seeSection7andAnnexA2.2.ReferencedDocuments2.1ASTMStandards:3D216MethodofTestforDistillationofNaturalGasoline(Withdrawn1988)4D323TestMethodforVaporPressureofPetroleumProducts(ReidMethod)D4057PracticeforManualSamplingofPetroleumandPetroleumProductsD4177PracticeforAutomaticSamplingofPetroleumandPetroleumProductsE230SpecificationandTemperature-ElectromotiveForce(EMF)TablesforStandardizedThermocouples2.2ANSIStandard:C96.1TemperatureMeasurementThermocouples.53.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1deposittendency,n—depositiontendencyofathinfilmorvaporisanindexofthepropensityofamaterialtoformcarbonaceousresiduesonhotsurfacesincontactwiththeliquidorvaporphaseofthesample.4.SummaryofTestMethod4.1Thetestspecimenisallowedtoflowslowlyinathinfilmoverasteeltestspecimeninaconstant-temperaturechamber(furnaceliner).Circulationofthesamplefromthesumptotheheatedsurfaceandbacktothesumpisaccom-plishedbyme...