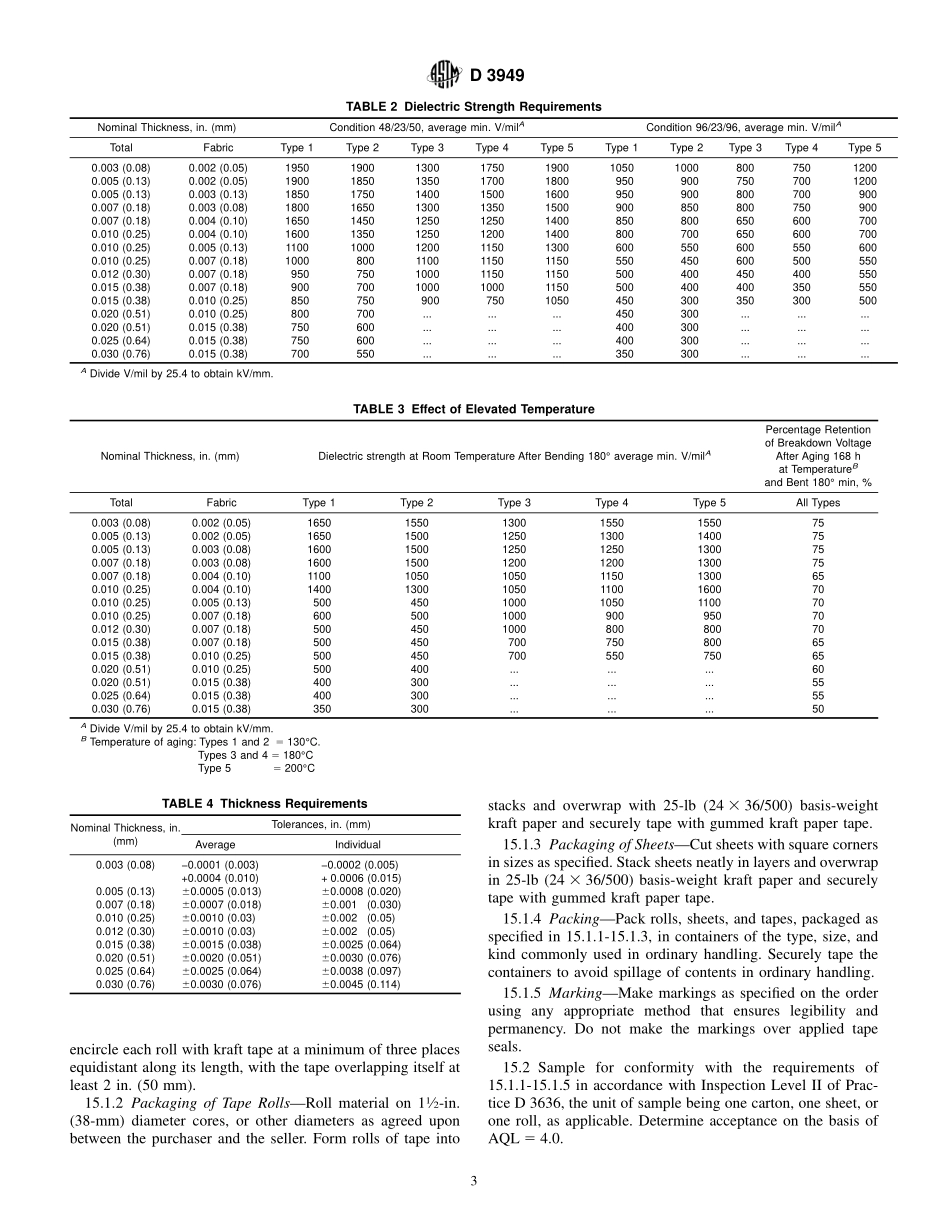

Designation:D3949–99AnAmericanNationalStandardStandardSpecificationforCoatedGlassFabricsUsedforElectricalInsulation1ThisstandardisissuedunderthefixeddesignationD3949;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoverswovenglassfabriccoatedwithfullycuredoleoresinousvarnish,epoxyresin,polyurethaneresin,orpolyesterresin.Excludedarecoatedpolyester-glassfabricandglassfabriccoatedwithsiliconeresinsandsiliconeelastomers.1.2Itisrecognizedthatseveralproperties,notablybreakingstrengthanddielectricstrength,arerelatedtothestyleofbasefabricusedforanyparticularthickness.Thisspecificationhasbeendevelopedformaterialsusingfabricswovenfromrela-tivelycoarse-filamentyarnsandinsomecasesfromrelativelyopen-weaveconstructions,andpropertyvaluesarefrequentlysomewhatlowerthaniffinerfilamentyarnsorcloserweaveconstructionswereused.Theuseristhereforealertedthatsignificantlyhigherlevelsofperformancetestvaluesmaybeobtainedthroughtheuseoftheselattertypesofalternatebaseconstructions.1.3Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.2.ReferencedDocuments2.1ASTMStandards:D902TestMethodsforFlexibleResin-CoatedGlassFab-ricsandGlassFabricTapesUsedforElectricalInsulation2D1711TerminologyRelatingtoElectricalInsulation2D1830TestMethodforThermalEnduranceofFlexibleSheetMaterialsUsedforElectricalInsulationbytheCurvedElectrodeMethod2D2518SpecificationforWovenGlassFabricsforElectricalInsulation3D3636PracticeforSamplingandJudgingQualityofSolidElectricalInsulatingMaterials33.Terminology3.1Definitions:Fordefinitionsoftermsusedinthisspeci-ficationrefertoTerminologyD1711.4.Classification4.1Thematerialsofthisspecificationareidentifiedaccord-ingtothetypeofcoatingapplied,asfollows:4.1.1Type1—Blackoleoresinousvarnish,4.1.2Type2—Yellowoleoresinousvarnish,4.1.3Type3—Ep...