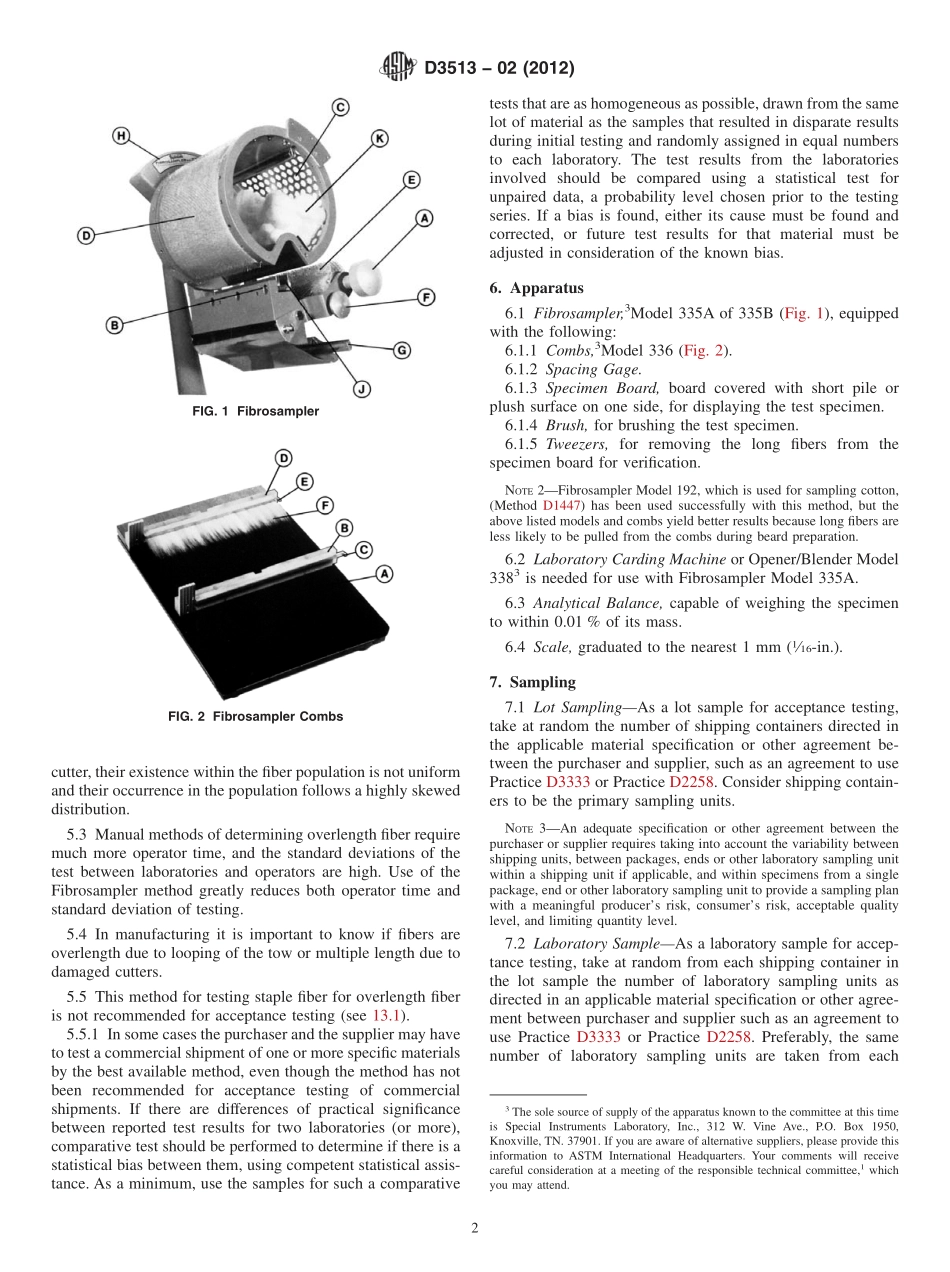

Designation:D3513−02(Reapproved2012)StandardTestMethodforOverlengthFiberContentofManufacturedStapleFiber1ThisstandardisissuedunderthefixeddesignationD3513;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthepercentbynumberofoverlengthormultiplelengthfibersinasampleofmanufacturedcutstaple.Themethodisapplicabletofibertakenimmediatelyaftermanufacturing,fromthebale,orfrompartiallyprocessedstock.NOTE1—Formeasurementoflengthandlengthdistributionofmanu-facturedstaplefibers,refertoTestMethodD5103.1.2ThistestmethodcoversproceduresusingtheFibrosam-plerModel335A(inch-poundunits),theFibrosamplerModel335B(SIunits),andFibrosamplercombsModel336.1.2.1TheFibrosamplerModel335Aisequippedwithasampleplatethathas15.8-mm(5⁄8-in.)diametersampleholesandisrecommendedforuseonblendedstapletakenfromthefiberblenderorfromacardingmachine.1.2.2TheFibrosamplerModel335Bisequippedwithasampleplatethathas10-mm(0.4-in.)diametersampleholesandisrecommendedforuseonunblendedstapleasmaybetakenfromthefibercutterorfromabaleofstaplefiber.1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasthestandard.Thevaluesstatedineachunitarenotexactequivalents;therefore,eachunitmustbeusedindependentlyoftheother.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D123TerminologyRelatingtoTextilesD1447TestMethodforLengthandLengthUniformityofCottonFibersbyPhotoelectricMeasurementD2258PracticeforSamplingYarnforTestingD3333PracticeforSamplingManufacturedStapleFibers,Sliver,orTowforTestingD3888TerminologyforYarnSpinningSyste...