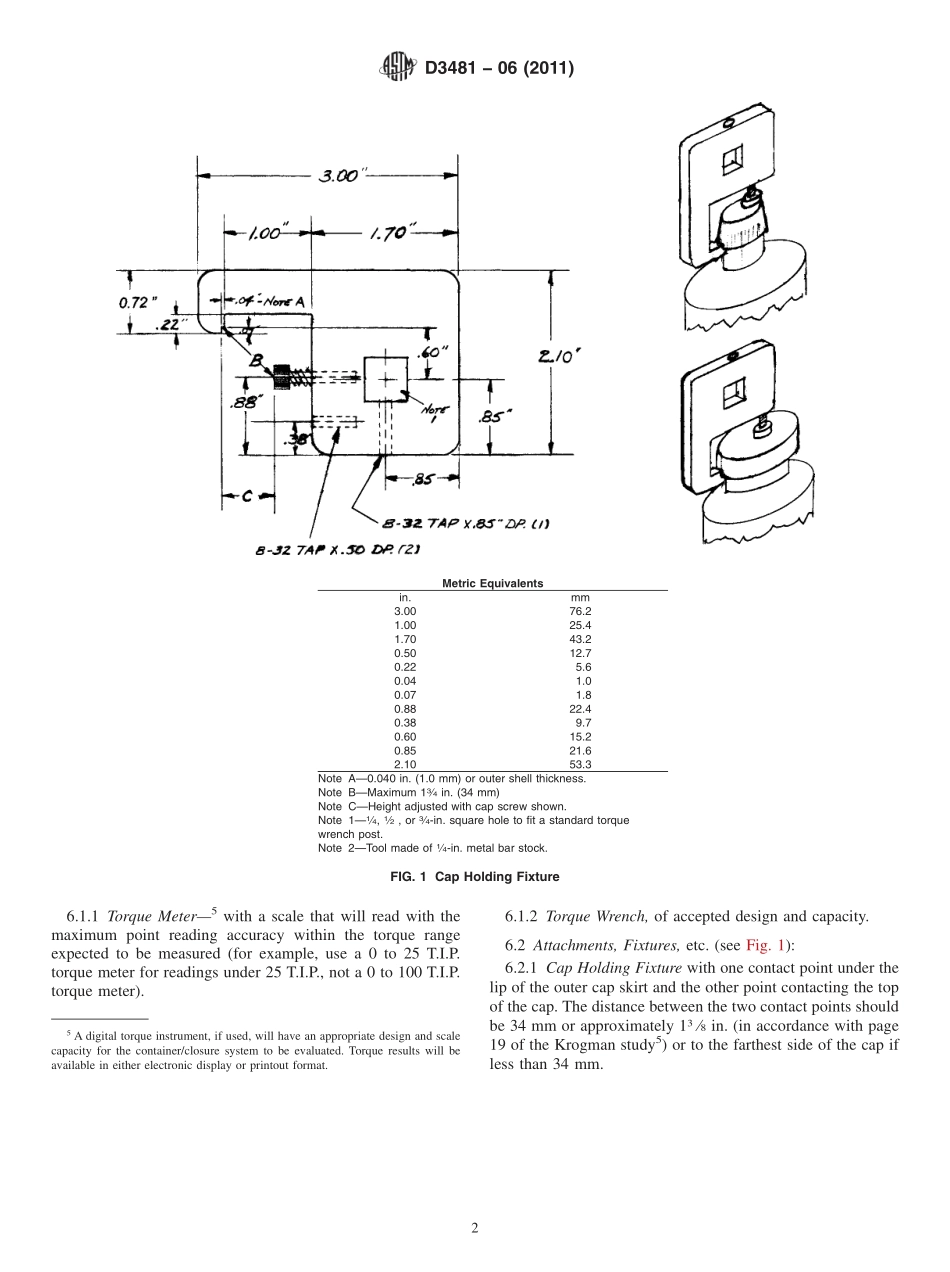

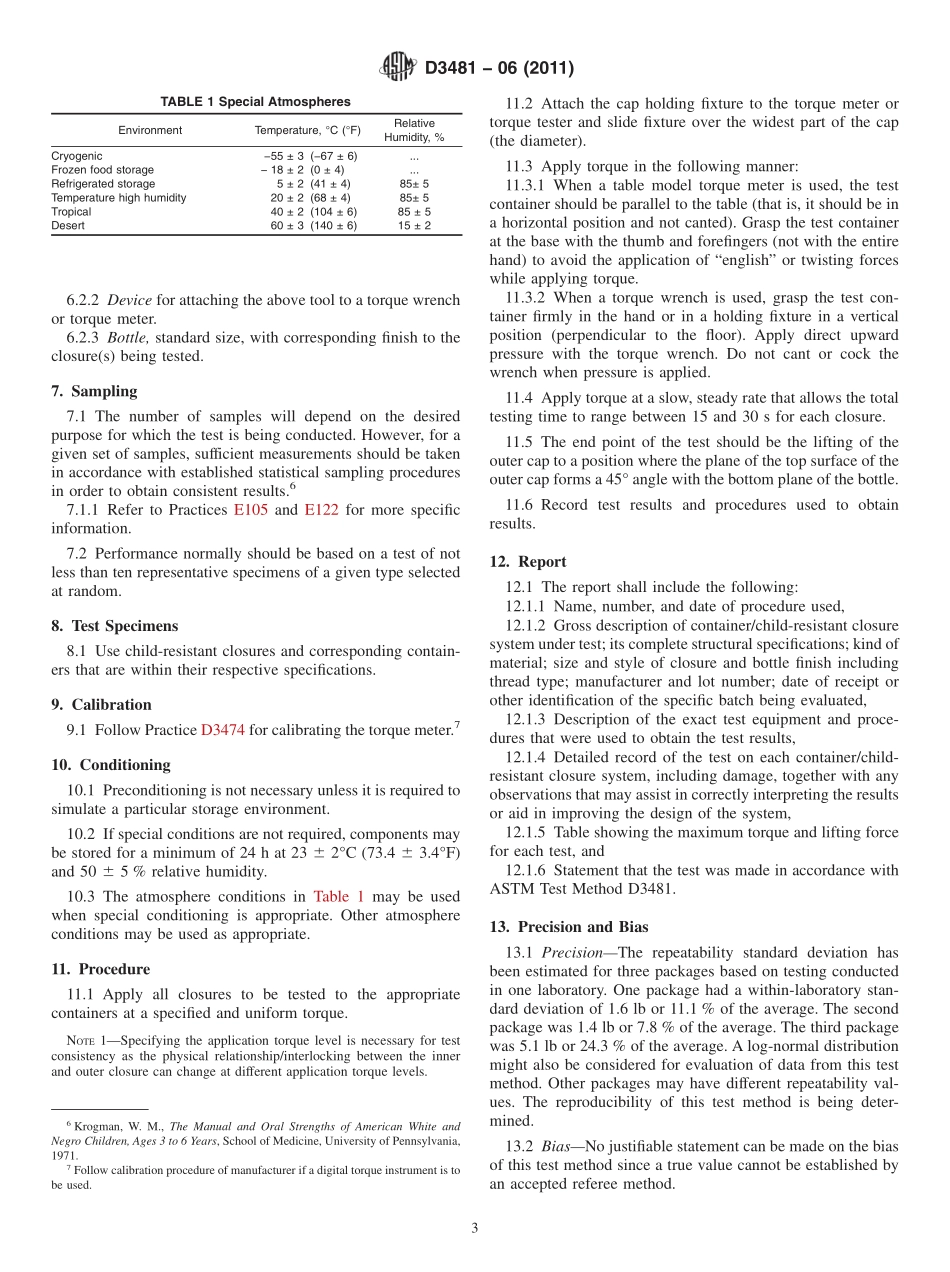

Designation:D3481−06(Reapproved2011)StandardTestMethodforManualShellingTwo-PieceChild-ResistantClosuresThatAreActivatedbyTwoSimultaneousDissimilarMotions1ThisstandardisissuedunderthefixeddesignationD3481;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthemeasurementoftheforcerequiredtoseparate(or“shell”)thesnap-fittedoutercapfromtheinnercapofTypeIA,IB,orICchild-resistantclosures.1.2Thistestmethoddoesnotmeasuretheforcerequiredtoseparatepartsofachild-resistantclosuresystemthatwereoriginally“screwed-on”insteadof“snapped-on”(forexample,pullacapoverorthroughcontinuousormulti-startthreadswhenthecapwasoriginallyscrewedon).1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Theinch-poundunitsgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D3474PracticeforCalibrationandUseofTorqueMetersUsedinPackagingApplicationsD3475ClassificationofChild-ResistantPackagesE105PracticeforProbabilitySamplingofMaterialsE122PracticeforCalculatingSampleSizetoEstimate,WithSpecifiedPrecision,theAverageforaCharacteristicofaLotorProcess2.2OtherDocuments:ISOBulletin2233Packaging—Complete,Filled,TransportPackages—Part2:ConditioningforTesting33.Terminology(seeClassificationD3475)3.1Definitions:3.1.1TypeIAchild-resistantclosure—atwo-piececontinu-ousthreadclosurerequiringarandompushdownwhileturning;noorientationofthepushdownforceisnecessary.3.1.2TypeIBchild-resistantclosure—atwo-piececontinu-ousthreadclosurerequiringalocalizedsqueezeforcewhileturning;theforcemustbeappliedtoadesignatedl...