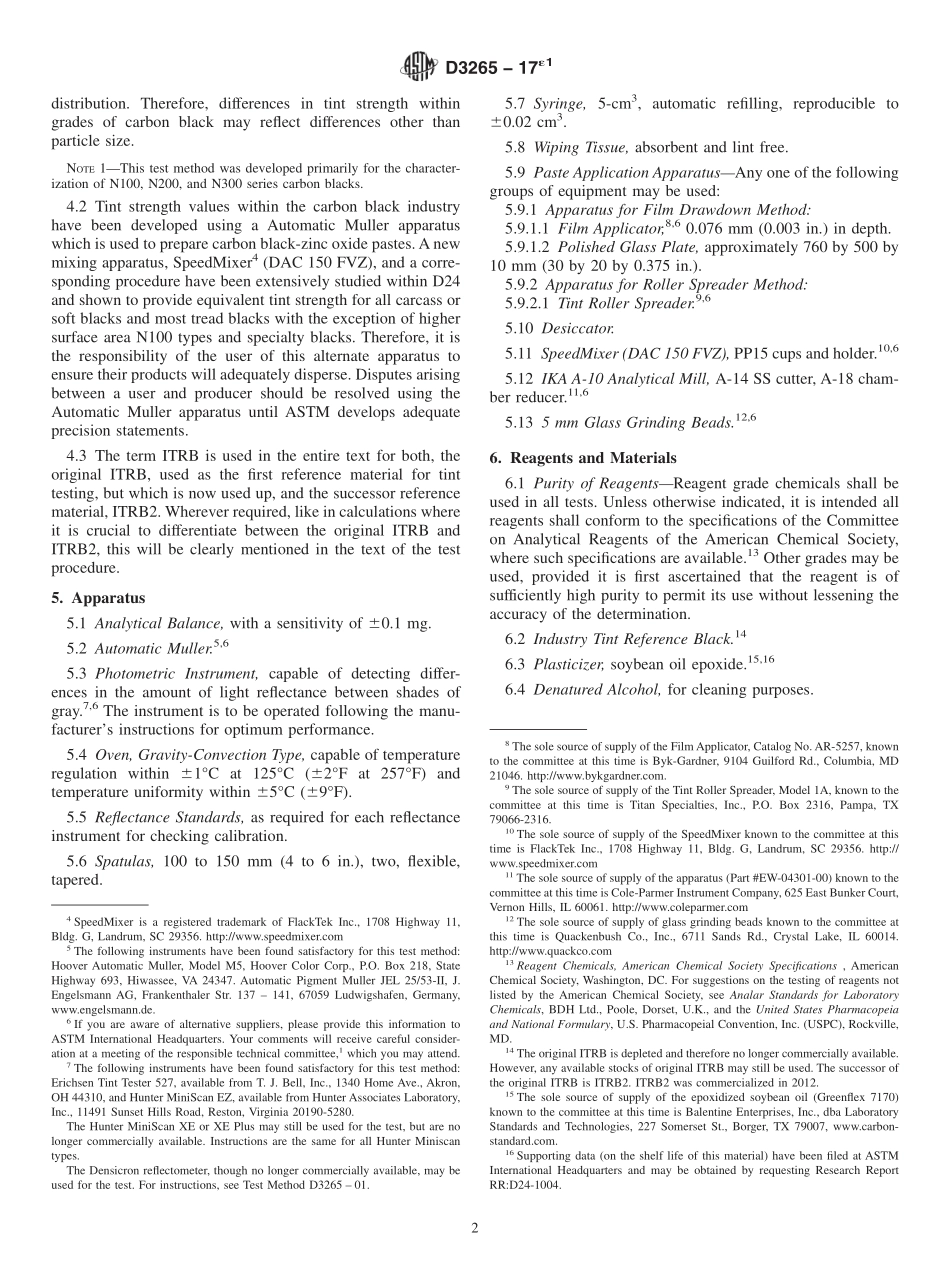

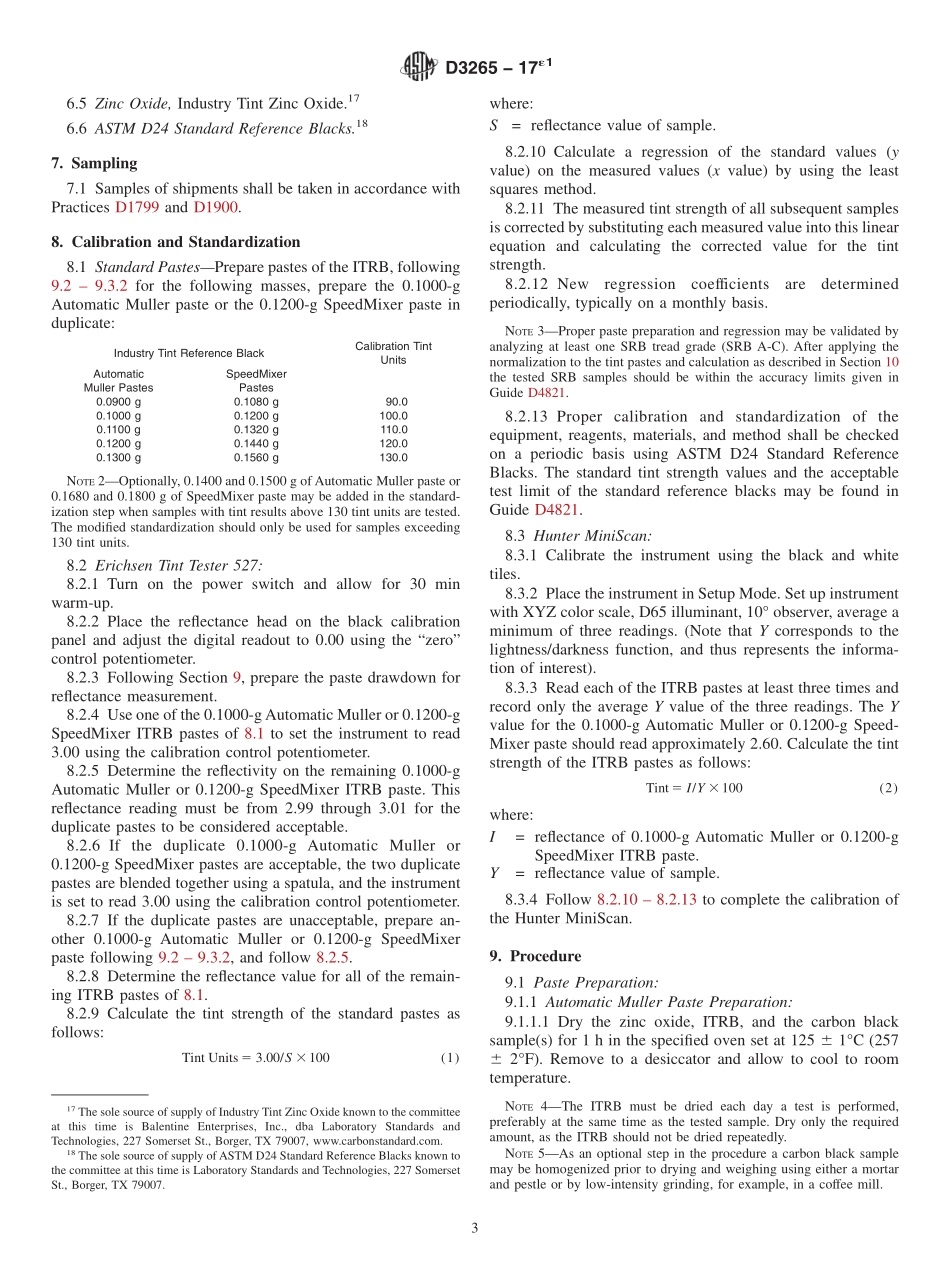

Designation:D3265−17´1StandardTestMethodforCarbonBlack—TintStrength1ThisstandardisissuedunderthefixeddesignationD3265;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ε1NOTE—Editoriallycorrectedfootnote15inAugust2017.1.Scope1.1Thistestmethodcoversthedeterminationofthetintstrengthofcarbonblackrelativetoanindustrytintreferenceblack(ITRB).1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,healthandenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D1799PracticeforCarbonBlack—SamplingPackagedShipmentsD1900PracticeforCarbonBlack—SamplingBulkShip-mentsD4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustriesD4821GuideforCarbonBlack—ValidationofTestMethodPrecisionandBias3.SummaryofTestMethod3.1Acarbonblacksampleismixedwithawhitepowder(zincoxide)andaliquidvehicle(epoxidizedsoybeanoil,ESO)toproduceablackorgraypaste.Thispasteisthenspreadtoproduceasurfacesuitableformeasuringthereflectanceofthemixturebymeansofaphoto-electricreflectancemeter.ThereflectanceofthetestedsampleisthencomparedtothereflectanceoftheITRBpreparedinthesamemanner.ThetintstrengthofthetestedsampleisexpressedasunitsofthereflectanceoftheITRBdividedbythereflectanceofthesampleandmultiplied...