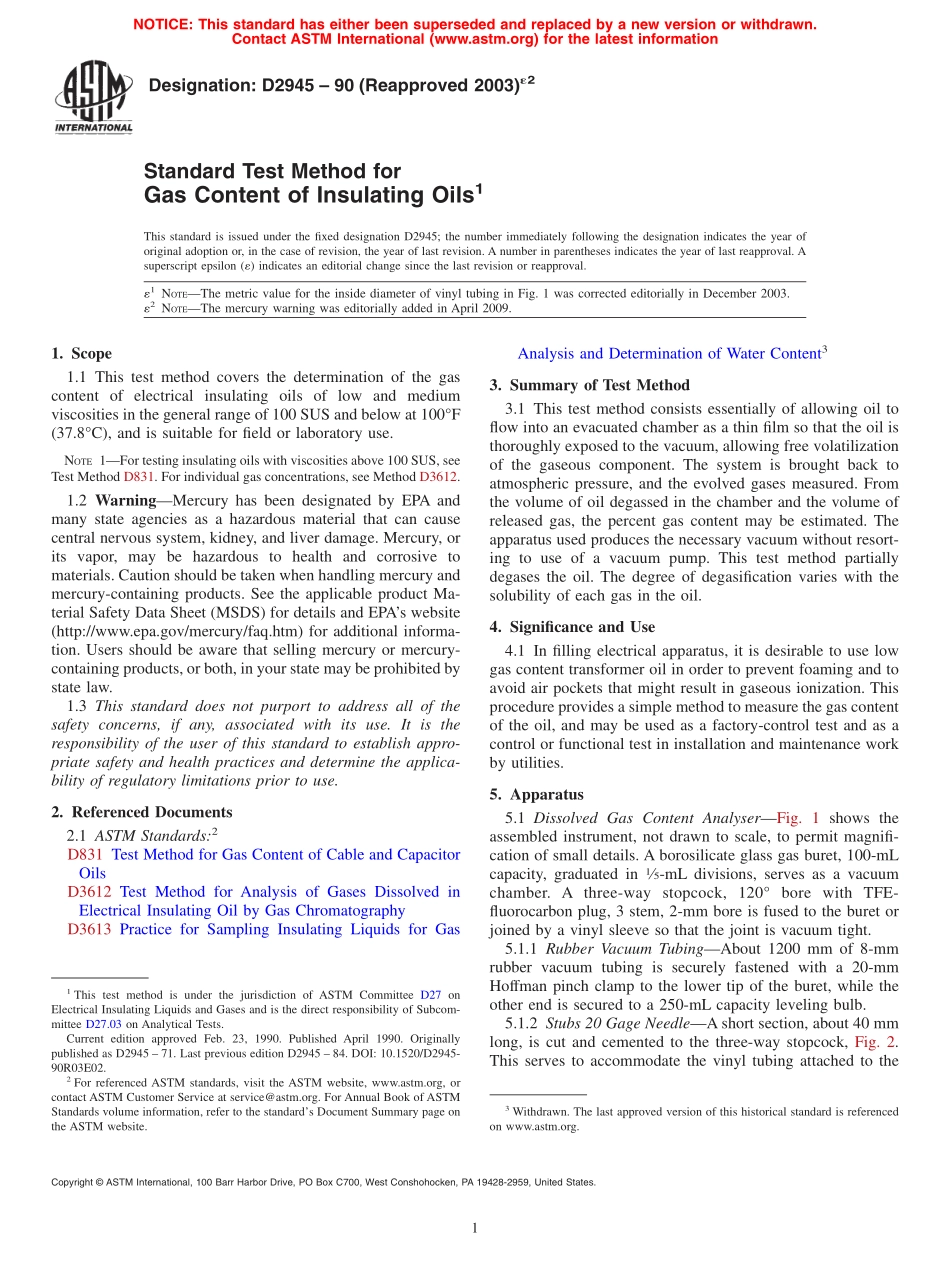

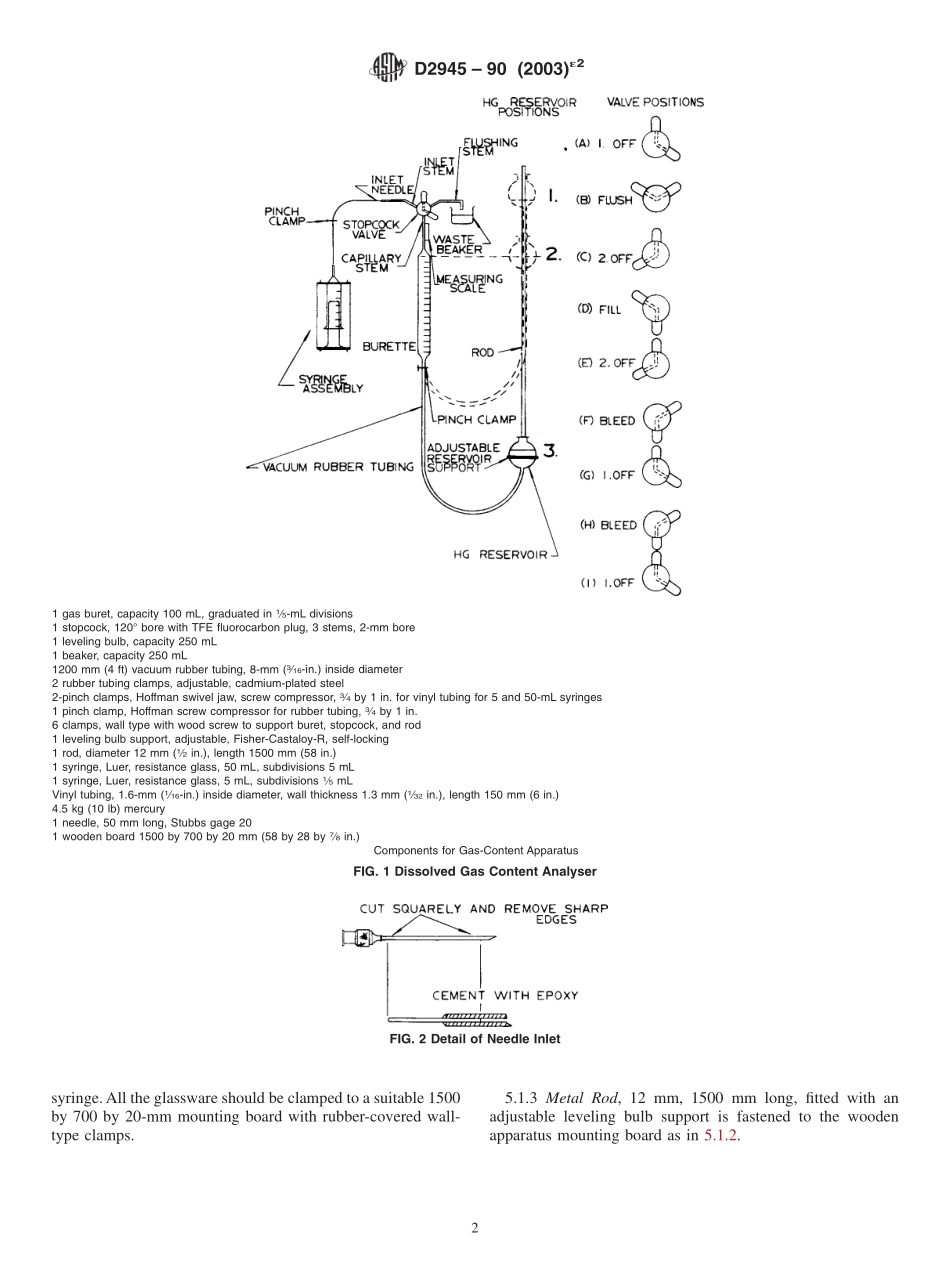

Designation:D2945–90(Reapproved2003)´2StandardTestMethodforGasContentofInsulatingOils1ThisstandardisissuedunderthefixeddesignationD2945;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.´1NOTE—ThemetricvaluefortheinsidediameterofvinyltubinginFig.1wascorrectededitoriallyinDecember2003.´2NOTE—ThemercurywarningwaseditoriallyaddedinApril2009.1.Scope1.1Thistestmethodcoversthedeterminationofthegascontentofelectricalinsulatingoilsoflowandmediumviscositiesinthegeneralrangeof100SUSandbelowat100°F(37.8°C),andissuitableforfieldorlaboratoryuse.NOTE1—Fortestinginsulatingoilswithviscositiesabove100SUS,seeTestMethodD831.Forindividualgasconcentrations,seeMethodD3612.1.2Warning—MercuryhasbeendesignatedbyEPAandmanystateagenciesasahazardousmaterialthatcancausecentralnervoussystem,kidney,andliverdamage.Mercury,oritsvapor,maybehazardoustohealthandcorrosivetomaterials.Cautionshouldbetakenwhenhandlingmercuryandmercury-containingproducts.SeetheapplicableproductMa-terialSafetyDataSheet(MSDS)fordetailsandEPA’swebsite(http://www.epa.gov/mercury/faq.htm)foradditionalinforma-tion.Usersshouldbeawarethatsellingmercuryormercury-containingproducts,orboth,inyourstatemaybeprohibitedbystatelaw.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D831TestMethodforGasContentofCableandCapacitorOilsD3612TestMethodforAnalysisofGasesDissolvedinElectricalInsulatingOilbyGasChromatographyD3613PracticeforSamplingInsulatingLiquidsforGasAnalysisandDeterminationofWaterContent33.SummaryofTestMethod3.1Thistestmethodconsistsessentiallyofallowingoiltoflowintoanevacuatedchambera...