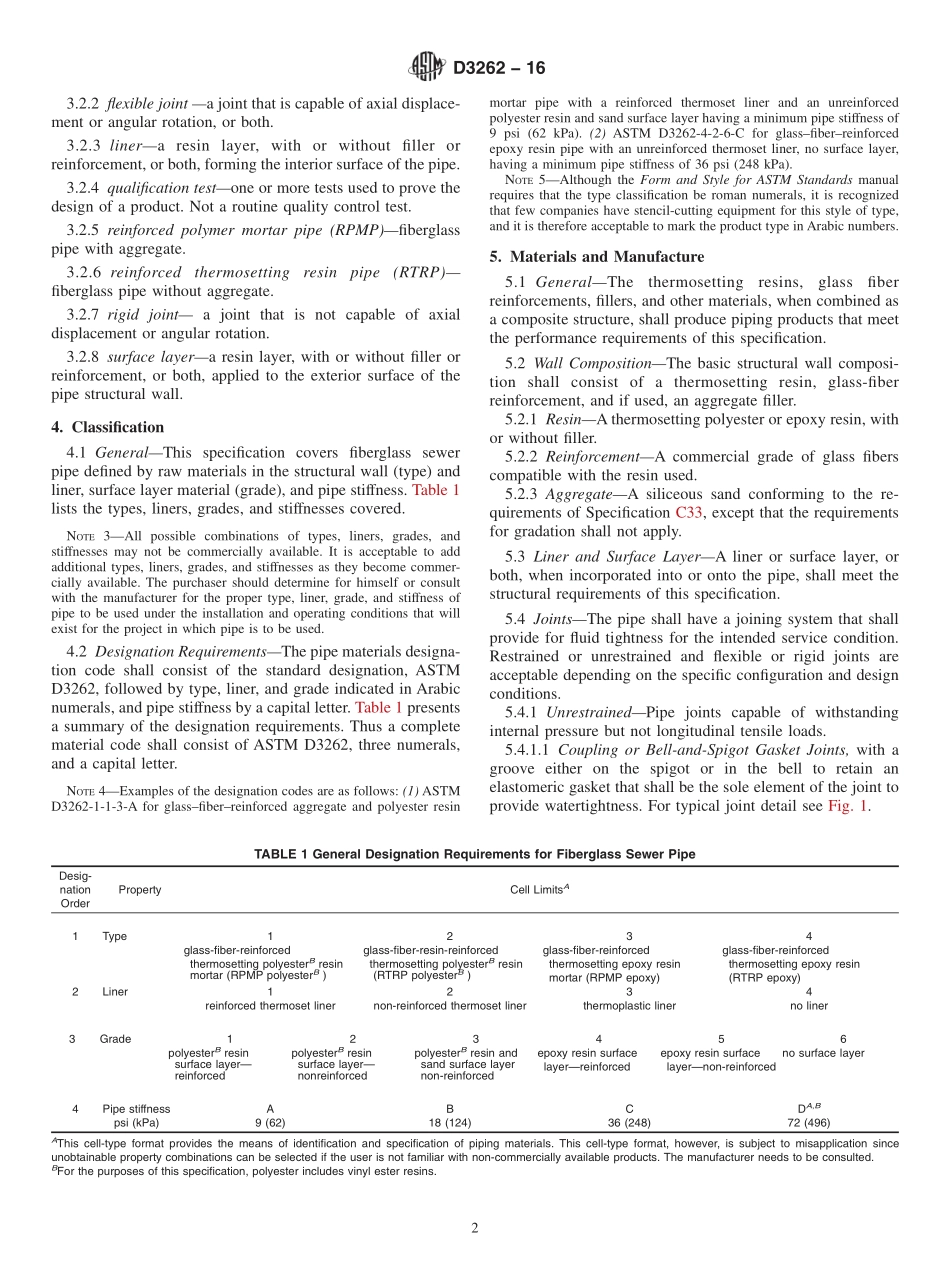

Designation:D3262−16AnAmericanNationalStandardStandardSpecificationfor“Fiberglass”(Glass-Fiber-ReinforcedThermosetting-Resin)SewerPipe1ThisstandardisissuedunderthefixeddesignationD3262;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversmachine-madefiberglasspipe,8in.(200mm)through156in.(4000mm),intendedforuseingravity-flowsystemsforconveyingsanitarysewage,stormwater,andsomeindustrialwastes.Bothglass-fiber-reinforcedthermosetting-resinpipe(RTRP)andglass-fiber-reinforcedpolymermortarpipe(RPMP)arefiberglasspipes.NOTE1—Forthepurposesofthisstandard,polymerdoesnotincludenaturalpolymers.1.2Althoughthisspecificationissuitedprimarilyforpipestobeinstalledinburiedapplications,itisacceptabletoapplyittotheextentapplicableforotherinstallationssuchas,butnotlimitedto,jacking,tunnelliningandslipliningrehabilitationofexistingpipelines.NOTE2—ThereisnoknownISOequivalenttothisstandard.1.3Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodportion,Section8,ofthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyproblems,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C33SpecificationforConcreteAggregatesD638TestMethodforTensilePropertiesofPlasticsD695TestMethodforCompressivePropertiesofRigidPlasticsD883TerminologyRelatingtoPlasticsD1600TerminologyforAbbreviatedTermsRelatingtoPlas-ticsD2412TestMethodforDeterminationofExternalLoadingCharacteristicsofPlasticPipebyParallel-PlateLoadingD2584TestMethodforIgnitionLossofCuredReinforcedResinsD2992Practicef...