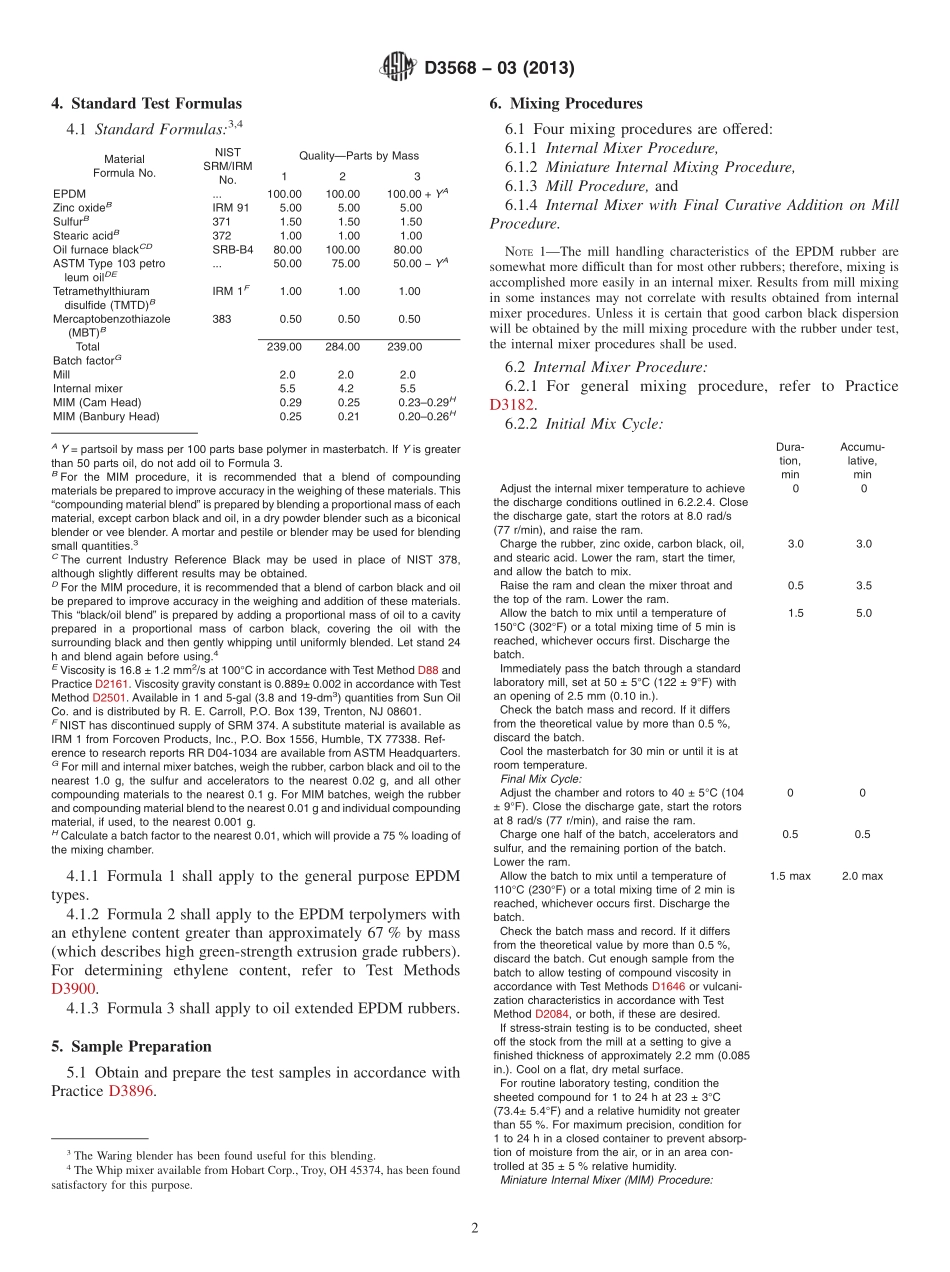

Designation:D3568−03(Reapproved2013)StandardTestMethodsforRubber—EvaluationofEPDM(EthylenePropyleneDieneTerpolymers)IncludingMixturesWithOil1ThisstandardisissuedunderthefixeddesignationD3568;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodsspecifythestandardmaterials,testformulas,mixingprocedures,andtestmethodsfortheevalu-ationandproductioncontrolofethylenepropylenedienerubbers(EPDM).1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesinparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D88TestMethodforSayboltViscosityD412TestMethodsforVulcanizedRubberandThermoplas-ticElastomers—TensionD1646TestMethodsforRubber—Viscosity,StressRelaxation,andPre-VulcanizationCharacteristics(MooneyViscometer)D2084TestMethodforRubberProperty—VulcanizationUsingOscillatingDiskCureMeterD2161PracticeforConversionofKinematicViscositytoSayboltUniversalViscosityortoSayboltFurolViscosityD2501TestMethodforCalculationofViscosity-GravityConstant(VGC)ofPetroleumOilsD3182PracticeforRubber—Materials,Equipment,andPro-ceduresforMixingStandardCompoundsandPreparingStandardVulcanizedSheetsD3896PracticeforRubberFromSyntheticSources—SamplingD3900TestMethodsforRubber—DeterminationofEthyl-eneUnitsinEthylene-PropyleneCopolymers(EPM)andinEthylene-Propylene-DieneTerpolymers(EPDM)byInfraredSpectrometryD4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustriesD5289TestMethodforRubberProperty—VulcanizationUsingRotorlessCureMetersD6204TestMethodforRubber—M...