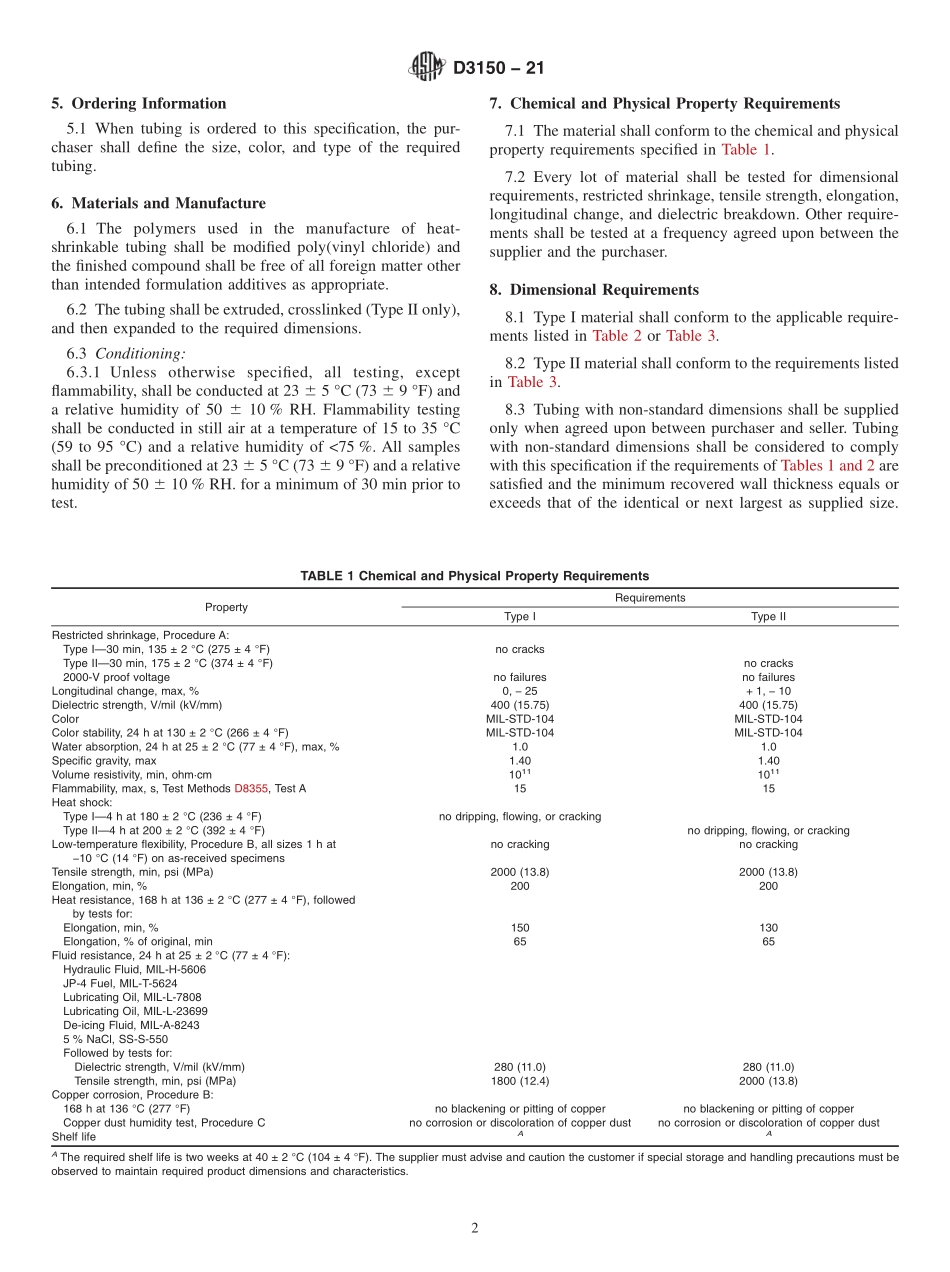

Designation:D3150−21StandardSpecificationforCrosslinkedandNoncrosslinkedPoly(VinylChloride)Heat-ShrinkableTubingforElectricalInsulation1ThisstandardisissuedunderthefixeddesignationD3150;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationappliestoflexible,crosslinkedandnoncrosslinkedpoly(vinylchloride)heat-shrinkabletubingforelectricalinsulatingpurposes.Itissuppliedinanexpandedformandwillshrinktoitsextrudeddiameterwhenheated.NOTE1—ThisstandardissimilarbutnotidenticaltoIEC60684–3–201.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.2.1Insomecases(includingthetitle),temperaturesaredescribedindegreesCelsiusonly.1.3Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D1711TerminologyRelatingtoElectricalInsulationD2671TestMethodsforHeat-ShrinkableTubingforElec-tricalUseD3636PracticeforSamplingandJudgingQualityofSolidElectricalInsulatingMaterialsD8355TestMethodsforFlammabilityofElectricalInsulat-ingMaterialsUsedforSleevingorTubingE176TerminologyofFireStandards2.2MilitaryStandards:3MIL-STD-104LimitsforElectricalInsulationColorMIL-H-5606HydraulicFluid,PetroleumBase,Aircraft,Missile,andOrdnanceMIL-T-5624TurbineFuel,Aviation,GradesJP-4andJP-5MIL-L-7808LubricatingOil,Aircraft,TurbineEngine,Syn-theticBaseMIL-L-23699LubricatingOil,Aircraft,TurbineEngines,SyntheticBaseMIL-A-8243Anti-IcingandDe-IcingDefrostingFluid2.3FederalStandard:4SS-S-550Sodium...