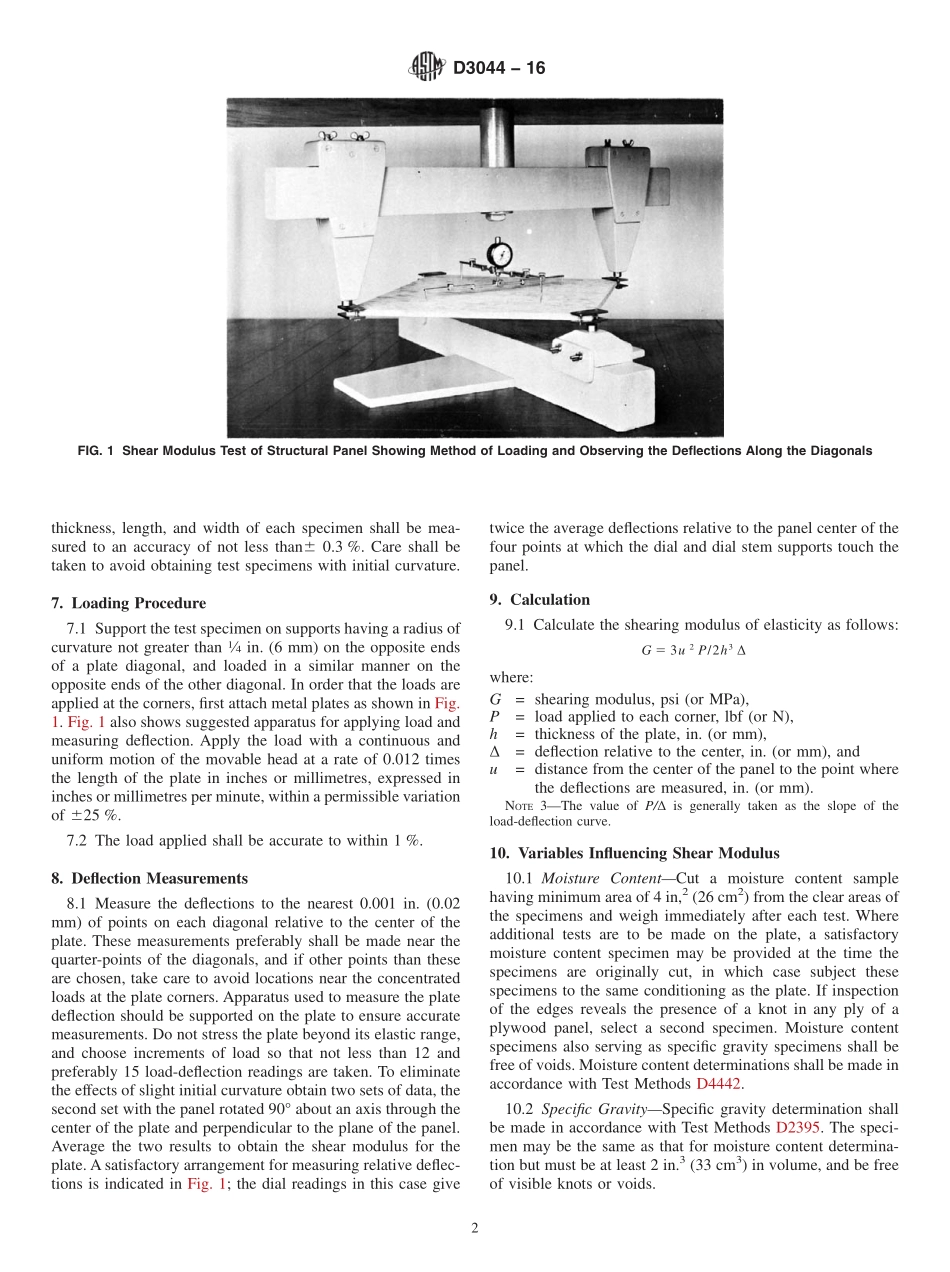

Designation:D3044−16StandardTestMethodforShearModulusofWood-BasedStructuralPanels1ThisstandardisissuedunderthefixeddesignationD3044;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversdeterminationoftheshearmodulusofwood-basedstructuralpanelsassociatedwithsheardistortionintheplaneofthepanels.Themethodisapplicabletoalltypesofwood-basedstructuralpanels.Thegraindirec-tionororientationoftheindividualplies,laminations,orlayersshallbeparallelorperpendiculartotheedgeofthetestspecimen.Iftheplies,laminations,orlayersareofdifferentmaterialorelasticproperties,themethodgivestheeffectiveshearingmodulus.Wood-basedstructuralpanelsinuseincludeplywood,orientedstrandboard,andcompositesofveneerandofwood-basedlayers.NOTE1—Thistestmethodisprimarilydesignedformaterialinwhichthegrainororientationoftheindividualplies,laminations,orlayersisparallelorperpendiculartotheedgeofthespecimen.Itmaybeused,however,forplywoodspecimensinwhichthegrainisat45°tothespecimenedgesifafour-plypanelwithallpliesofthesamethicknessisused.ThecontrollingconditionisthattheEI(modulusofelastic-ity×momentofinertia)valuesalongbothdiagonalsshallbeequal.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2395TestMethodsforDensityandSpecificGravity(Rela-tiveDensity)ofWoodandWood-BasedMaterialsD2718TestMethodsforStructuralPanelsinPlanarShear(RollingShear)D4442TestMethodsforDirectMo...