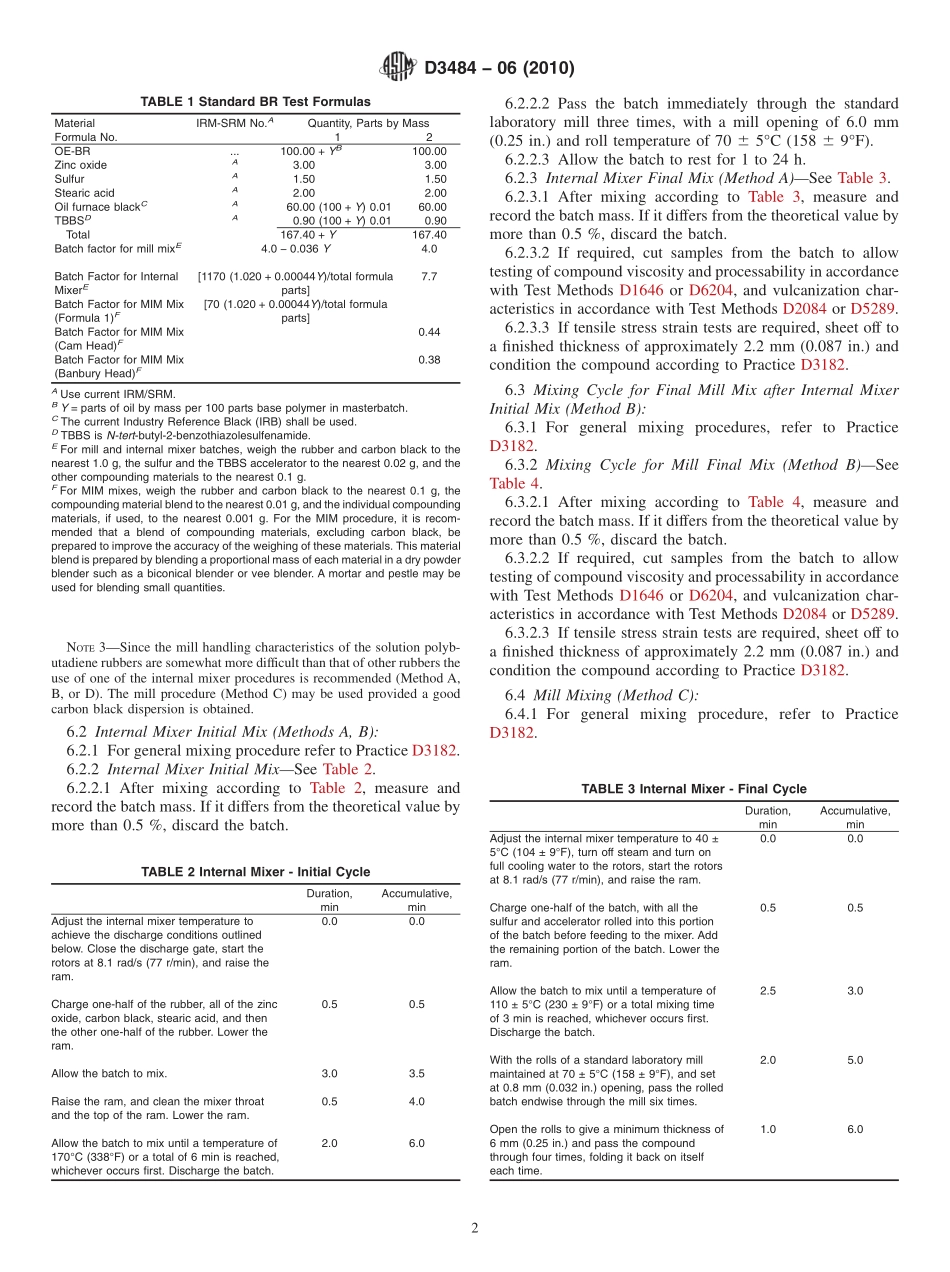

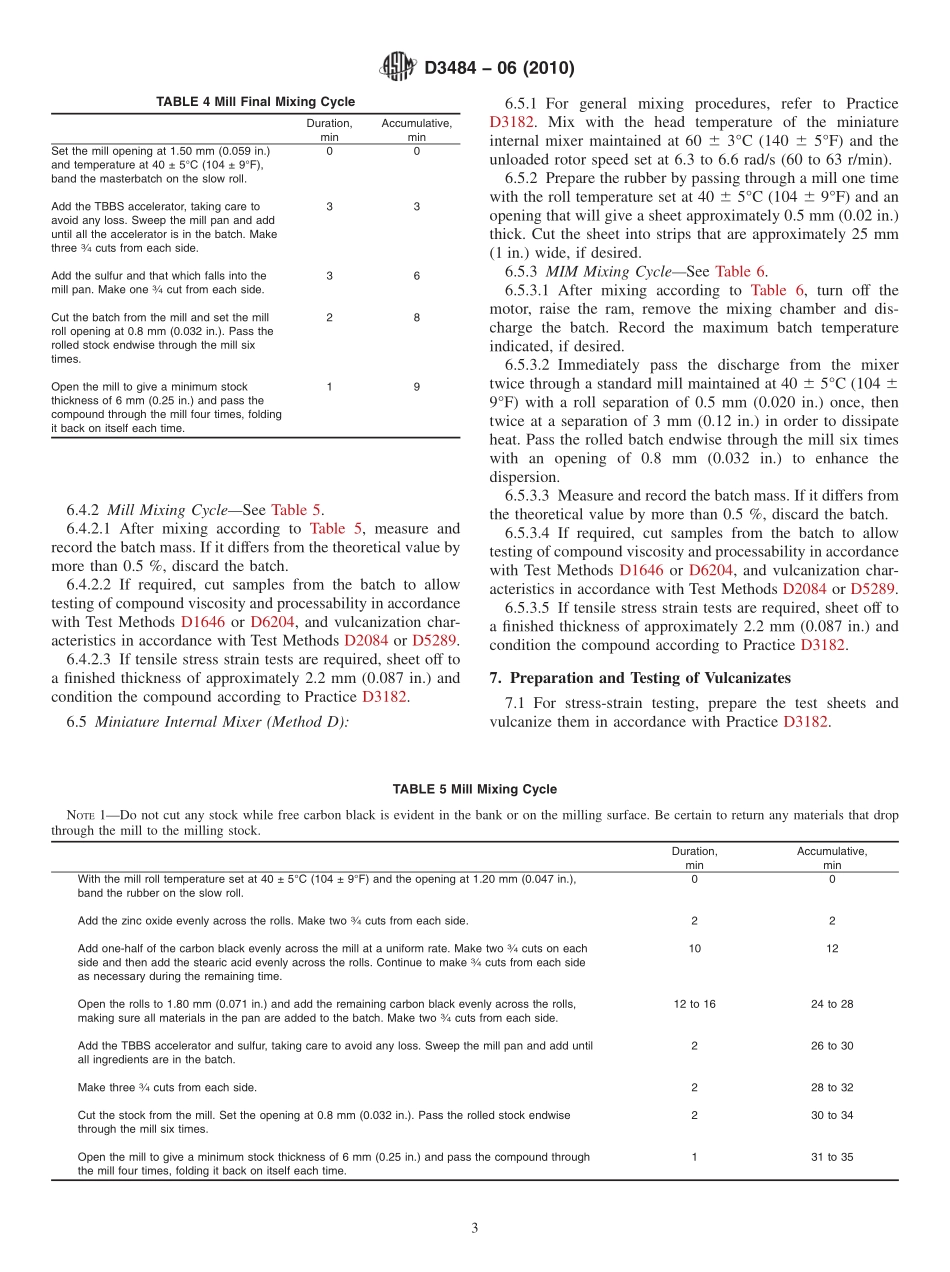

Designation:D3484−06(Reapproved2010)StandardTestMethodsforRubber—EvaluationofOil-ExtendedSolutionBR(PolybutadieneRubber)1ThisstandardisissuedunderthefixeddesignationD3484;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscoverthestandardmaterials,testformulas,mixingprocedures,andtestmethodsfortheevalu-ationandproductioncontrolofoil-extendedpolybutadienerubber(OE-BR)polymerizedinanappropriatesolution.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D412TestMethodsforVulcanizedRubberandThermoplas-ticElastomers—TensionD1646TestMethodsforRubber—Viscosity,StressRelax-ation,andPre-VulcanizationCharacteristics(MooneyVis-cometer)D2084TestMethodforRubberProperty—VulcanizationUsingOscillatingDiskCureMeterD3182PracticeforRubber—Materials,Equipment,andPro-ceduresforMixingStandardCompoundsandPreparingStandardVulcanizedSheetsD3896PracticeforRubberFromSyntheticSources—SamplingD4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustriesD5289TestMethodforRubberProperty—VulcanizationUsingRotorlessCureMetersD6204TestMethodforRubber—MeasurementofUnvulca-nizedRheologicalPropertiesUsingRotorlessShearRhe-ometers2.2ISOStandard:ISO2476Rubber,Butadiene(BR)SolutionPolymerizedTypes—TestRecipeandEvaluationCharacteristics33.SignificanceandUse3.1Thesetestsaremainlyintendedforrefereepurposesbutmayalsobeusedforqualitycontrolofrubberproduction.Theymaybeusedinresearchanddevelopmentwor...