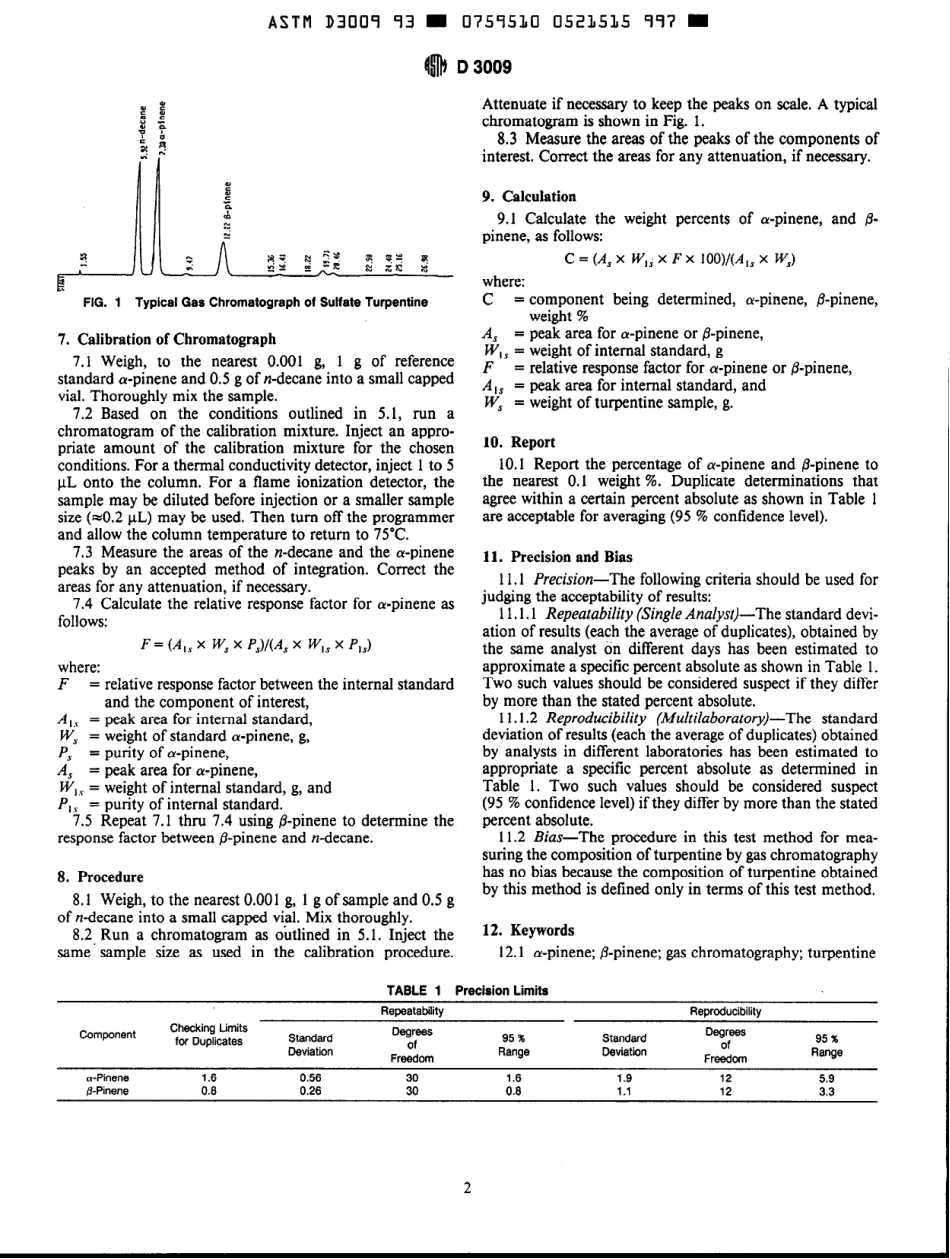

ASTMD300993-0759530052L5L4T50-Designation:D3009-93AMEHICANSOCIETYFORTESTINGANDMATERIALS1916RaceStPhiladelphia,Pa19103ReprintedfromtheAnnualBookofASTMStandards.CopyrightASTMIfnotMedinthecwrentcombinedIndex,willappearinthenetiedition.StandardTestMethodforCompositionofTurpentinebyGasChromatography’ThisstandardisissuedunderthefixeddesignationD3009;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(0indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthecomposition,specificallythea-pineneand&pinenecontent,ofwood,gum,andsulfateturpentinebypackedcolumngaschromatography.TermsaredefinedinTerminologyD804.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyproblems,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:DI3SpecificationforSpiritsofTurpentine2D804TerminologyRelatingtoNavalStores,IncludingTallOilandRelatedProducts23.SummaryofTestMethod3.1Aweightedmixtureofthesampleandinternalstan-dardisprepared,analiquotisinjectedintoa75°Cchromato-graphiccolumn,andthetemperatureprogrammedto2Oo’Ctoobtainthechromatogram.Thepeakareasforthecompo-nentstobedeterminedandalsofortheinternalstandardaremeasured.Thepercentagesofthecomponentspresentarecalculatedfromtheproductofthepeakareaofthecompo-nent,weightofinternalstandard,andthecalibrationfactordividedbytheproductoftheweightofsampleandpeakareaoftheinternalstandard.4.SignificanceandUse4.1EarliermethodsforcharacterizingturpentinewerebasedonphysicalpropertiesbasedonphysicalpropertiessuchasthoseinSpecificationD13.Asturpentinebecamewidelyusedasachemicalrawmaterialitschemicalcompo-sition,especiallyitscY-pineneand@-pinenecontent,becamemoreimportant.Thegaschromatographictechniquede-...