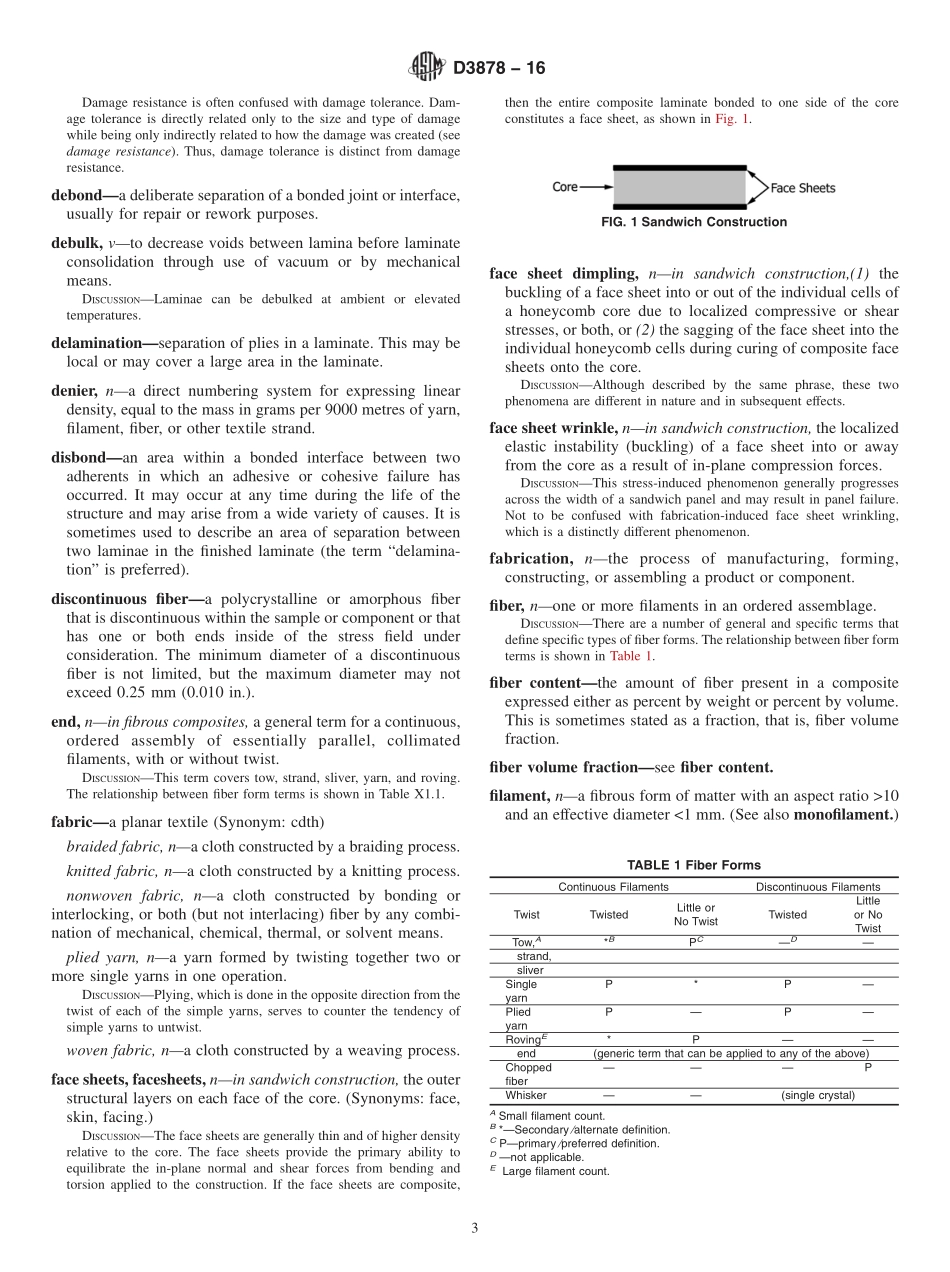

Designation:D3878−16StandardTerminologyforCompositeMaterials1ThisstandardisissuedunderthefixeddesignationD3878;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thesedefinitionscovergenericterms,includingtermsofcommercialimportance,thatappearinoneormorestan-dardsoncompositescontaininghigh-modulus(greaterthan20-GPa(3×106psi))fibers.1.2Thedefinitionscover,inmostcases,specialmeaningsusedinthecompositesindustry.Noattempthasbeenmadetoincludecommonmeaningsofthesametermsasusedoutsidethecompositesindustry.1.3Definitionsincludedhave,ingeneral,beenapprovedasstandard.2.ReferencedDocuments2.1ASTMStandards:2D123TerminologyRelatingtoTextiles2.2IndustryStandard:3CMH-17CompositeMaterialsHandbook3.Terminology3.1Definitions:645°laminate—abalancedsymmetriclaminatecomposedofonly+45°pliesand−45°plies.angleplylaminate—anybalancedlaminateconsistingofplusandminusthetaplieswherethetaisanacuteanglewithrespecttoareferencedirection.balancedlaminate—anylaminatethatcontainsoneplyofminusthetaorientationwithrespecttothelaminateprincipalaxisforeveryidenticalplywithaplusthetaorientation.bond,n—theactofadheringonesurfacetoanother,withorwithouttheuseofanadhesiveattheinterface.co-cure,cocure—seeCure.co-bond,cobond,n—theactofcuring(orconsolidating)andbondingonesemi-soliddetail(e.g.uncuredthermosetpolymerorathermoplasticpolymer)toasoliddetailinasingleprocessthroughprincipalactionofthematrix,possiblywiththeinclusionofaseparatelayerofadhesiveattheinterface.secondarybond,n—theactofbondingtwoormorealready-curedthermosetcompositeorothersoliddetails,duringwhichtheonlychemicalorthermalreaction,orboth,occurringisthecuringoftheadhesivelayerattheinterface.DISCUSSION—Forexample,apreviouslycuredcompositeormetaldoubl...