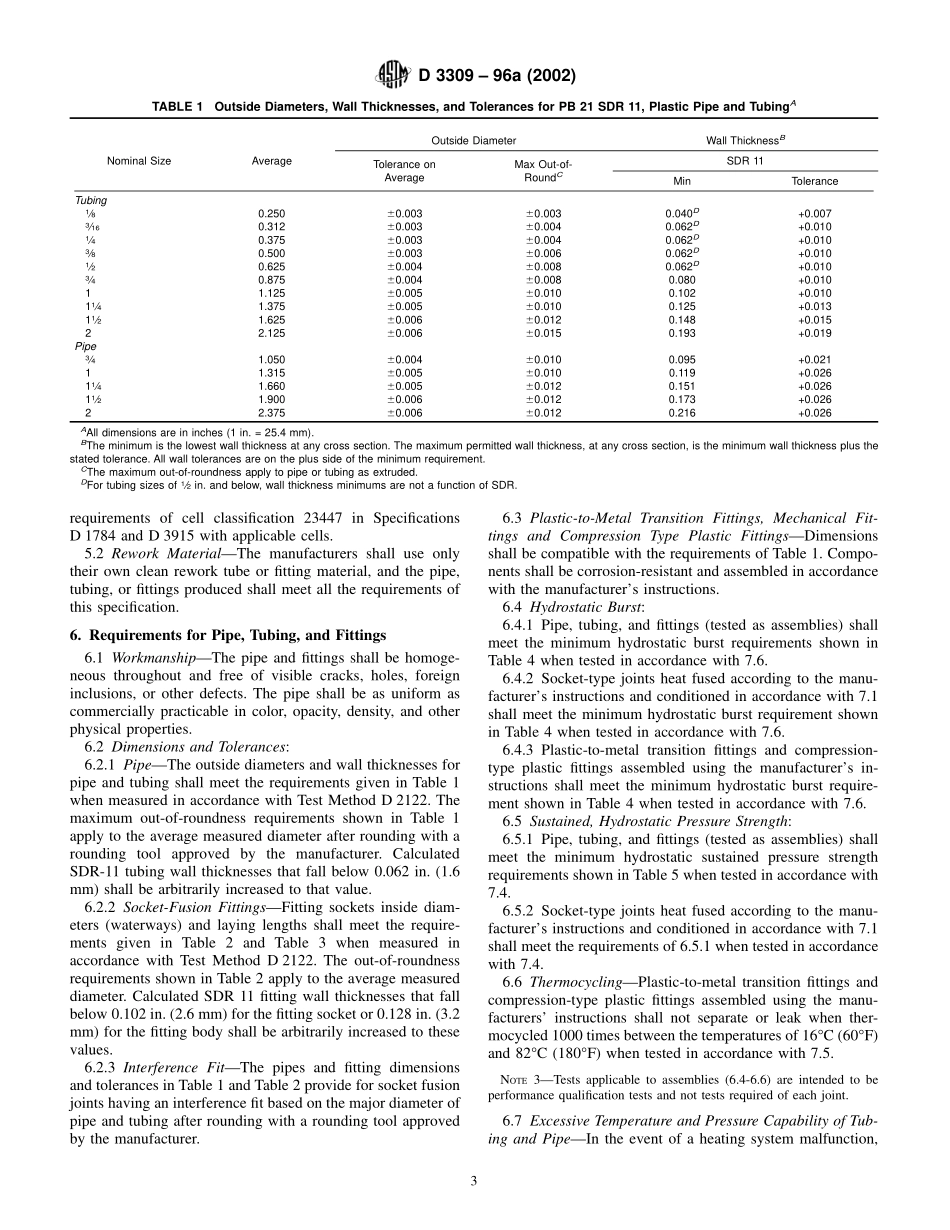

Designation:D3309–96a(Reapproved2002)AnAmericanNationalStandardStandardSpecificationforPolybutylene(PB)PlasticHot-andCold-WaterDistributionSystems1ThisstandardisissuedunderthefixeddesignationD3309;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thisspecificationcoversrequirements,testmethods,andmethodsofmarkingforpolybutyleneplasticsystemcomponentsmadeinonestandarddimensionratioandin-tendedfor0.69MPa(100psi)waterserviceuptoandincluding82°C(180°F).Thesecomponentscomprisepipeandtubing,socket-fusionfittings,compressionfittings,mechanicalfittings,andplastic-to-metaltransitionfittings.Requirementsandtestmethodsareincludedforsustained,hydrostaticpres-surestrength,thermocyclingresistance,jointstrength,anddimensionsandtolerancesforpipeandsocketfusionfittings.Thecomponentscoveredbythisspecificationareintendedforuseinhot-andcold-waterpotablewaterserviceanddistribu-tionsystemsandsuchnon-potablewaterapplicationsasbuildingservicespiping,waterheatingandcoolingsystems,firesprinklerapplications,andothermiscellaneousapplica-tionsinvolvingthetransportofwater,ethyleneglycolsolu-tions,orotheraqueousliquidsshownnottoadverselyaffectPBperformance.1.2Thetextofthisspecificationreferencesnotes,footnotes,andappendixeswhichprovideexplanatorymaterial.Thesenotesandfootnotes(excludingthoseintablesandfigures)shallnotbeconsideredasrequirementsofthespecification.1.3ThevaluesinSIunitsarethestandard.Thevaluesstatedinparenthesesareforinformationonly.NOTE1—Suggestedhydrostaticdesignstressesandhydrostaticpres-sureratingsforpipe,tubing,andfittingsarelistedinAppendixX1.Design,assembly,andinstallationconsiderationsarediscussedinAppen-dixX2.Anoptionalperformancequalificationandanin-plantqualitycontrolprogramarerecommende...