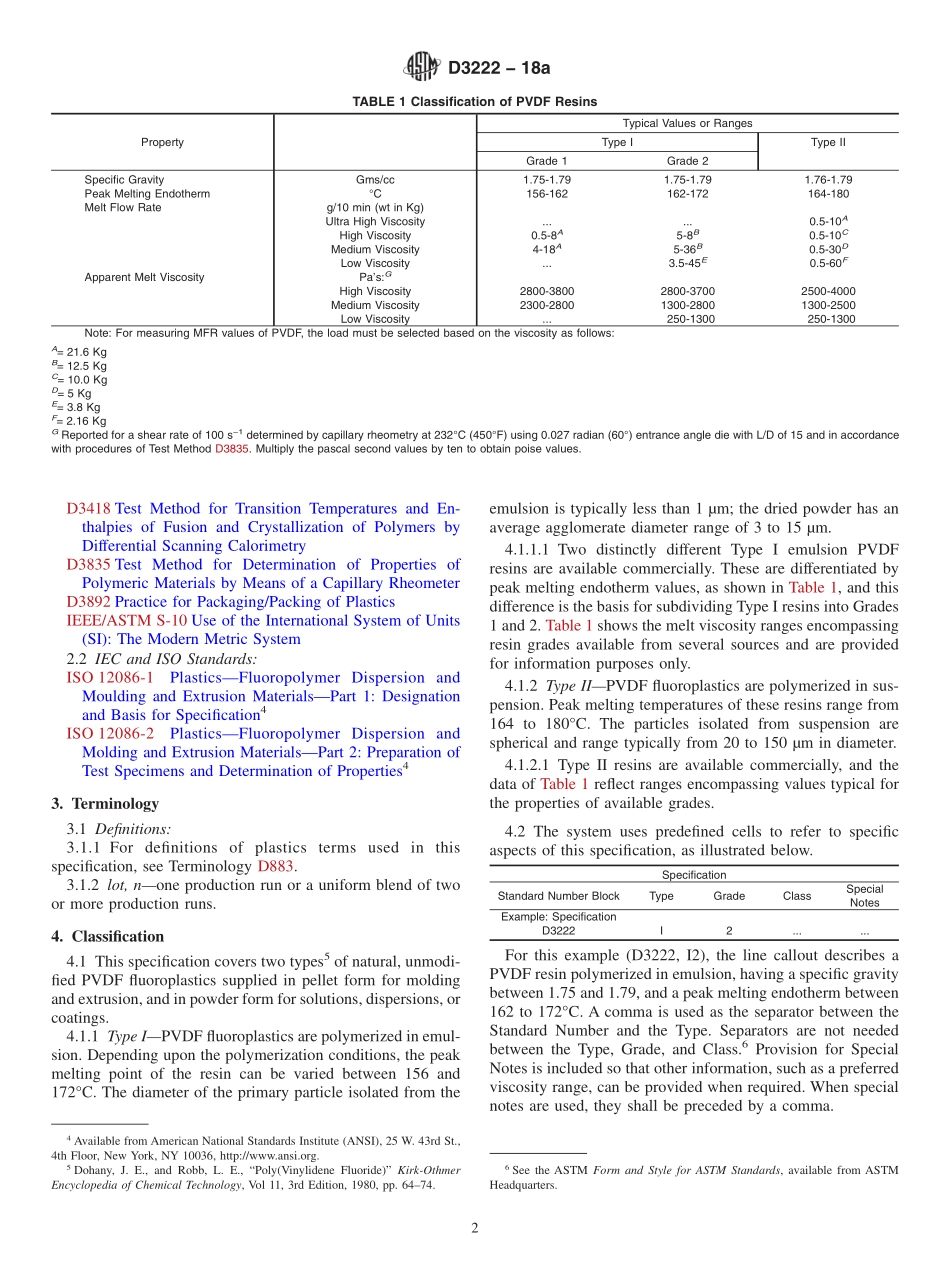

Designation:D3222−18aStandardSpecificationforUnmodifiedPoly(VinylideneFluoride)(PVDF)MoldingExtrusionandCoatingMaterials1ThisstandardisissuedunderthefixeddesignationD3222;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thisspecificationcoversmeltprocessablemoldingandextrusionmaterials,aswellascoatingmaterialsofpoly(vi-nylidenefluoride)fluoroplastic,commonlyabbreviatedPVDF(orPVF2inscientificliterature).Thisspecificationcoversthermoplasticresinmaterialssuppliedinpelletorpowderform.1.2Thisspecificationappliesonlytothevirginhomopoly-merpreparedfromvinylidenefluoride,notcopolymers,reinforced,filledgradesorspecialgradeswithadditivesortreatmentsformodificationofattributes.1.3ThetestsinvolvedareintendedtoprovideinformationforspecificationofunmodifiedPVDFhomopolymerresins.Itisnotthepurposeofthisspecificationtoprovideengineeringdatafordesignpurposes.1.4PVDFfluoroplasticsmeltbetween156and180°C(312and356°F)andarethermallystableuptoabout370°C(698°F).(Warning—Evolutionofcorrosiveandtoxichydrogenfluo-ridecanoccurundercertainconditions.)1.5ThevaluesstatedinSIunits,asdetailedinIEEE/ASTMS-10,aretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.NOTE1—PVDFexhibitspolymorphism.2Thetypeandextentofcrystallinestructurevarieswiththethermomechanicalhistoryofthesample.Specimenspreparedbytechniquesdifferentthanprescribedinthisspecificationcanhavepropertiesthatvaryfromthevaluesspecified.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.Specificprecautionarystatementsareg...