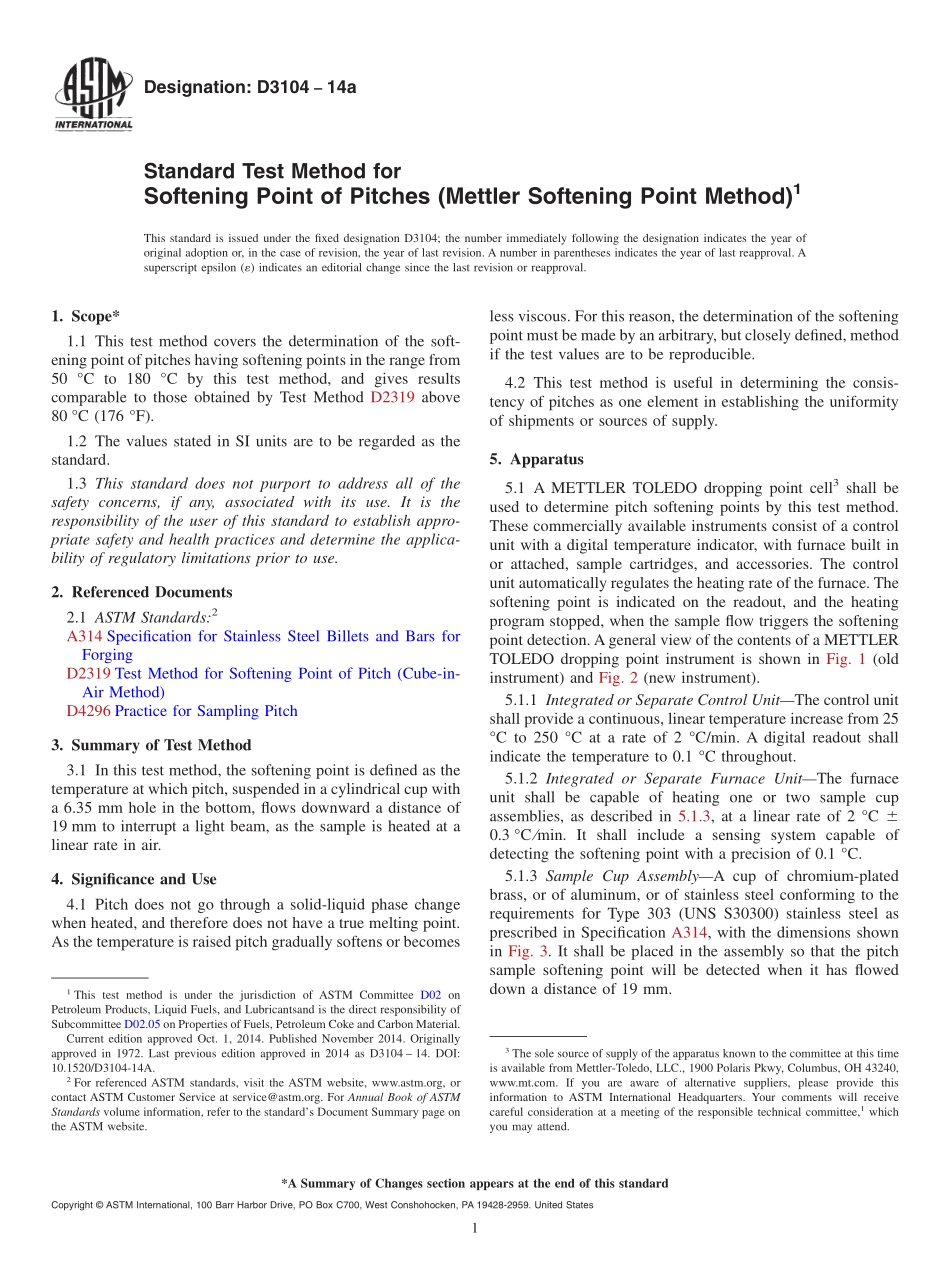

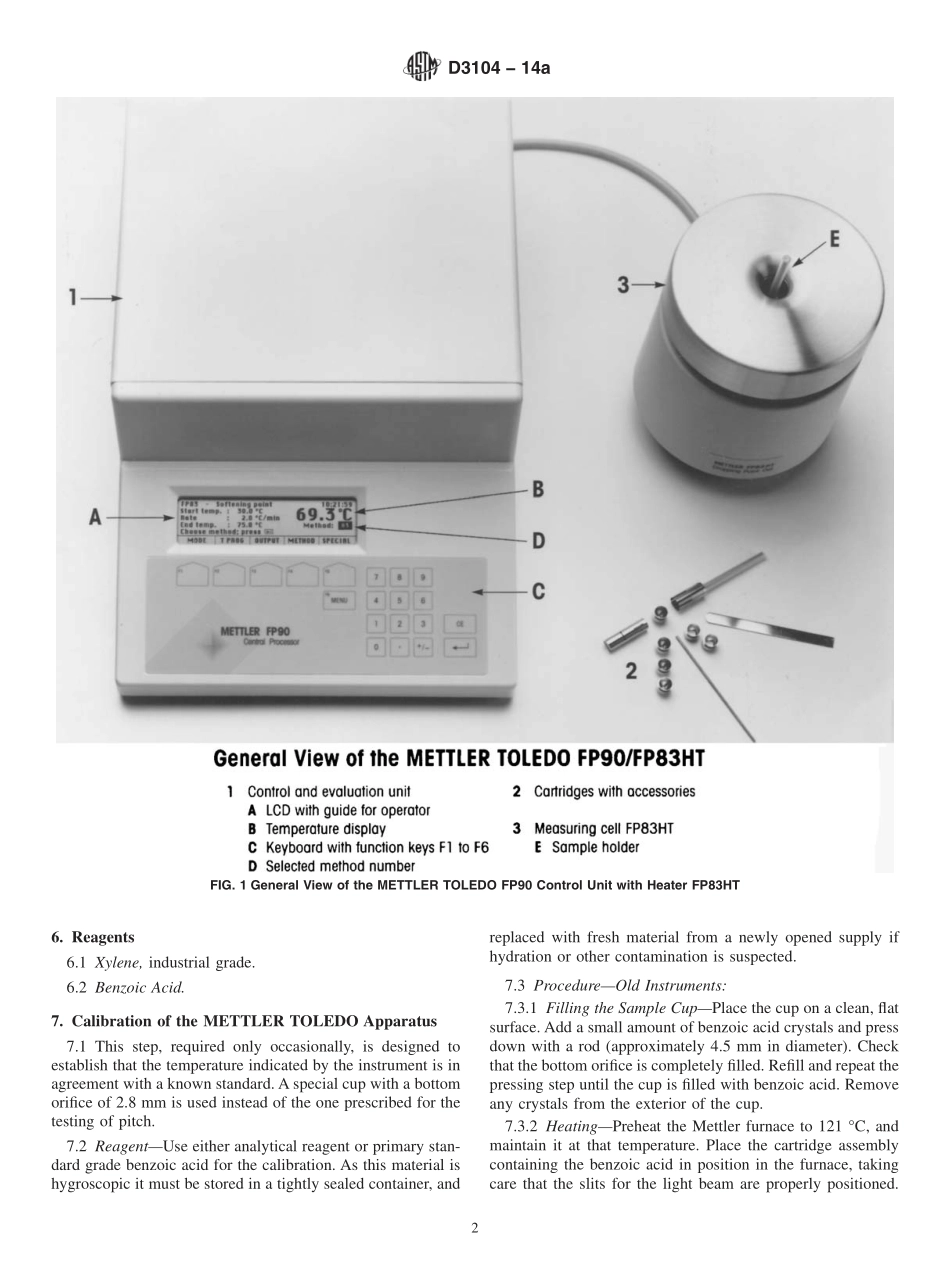

Designation:D3104−14aStandardTestMethodforSofteningPointofPitches(MettlerSofteningPointMethod)1ThisstandardisissuedunderthefixeddesignationD3104;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversthedeterminationofthesoft-eningpointofpitcheshavingsofteningpointsintherangefrom50°Cto180°Cbythistestmethod,andgivesresultscomparabletothoseobtainedbyTestMethodD2319above80°C(176°F).1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A314SpecificationforStainlessSteelBilletsandBarsforForgingD2319TestMethodforSofteningPointofPitch(Cube-in-AirMethod)D4296PracticeforSamplingPitch3.SummaryofTestMethod3.1Inthistestmethod,thesofteningpointisdefinedasthetemperatureatwhichpitch,suspendedinacylindricalcupwitha6.35mmholeinthebottom,flowsdownwardadistanceof19mmtointerruptalightbeam,asthesampleisheatedatalinearrateinair.4.SignificanceandUse4.1Pitchdoesnotgothroughasolid-liquidphasechangewhenheated,andthereforedoesnothaveatruemeltingpoint.Asthetemperatureisraisedpitchgraduallysoftensorbecomeslessviscous.Forthisreason,thedeterminationofthesofteningpointmustbemadebyanarbitrary,butcloselydefined,methodifthetestvaluesaretobereproducible.4.2Thistestmethodisusefulindeterminingtheconsis-tencyofpitchesasoneelementinestablishingtheuniformityofshipmentsorsourcesofsupply.5.Apparatus5.1AMETTLERTOLEDOdroppingpointcell3shallbeusedtodeterminepitchsofteningpointsbythistestmethod.Thesecommerciallyavailableinstrumentsconsistofacontrolunitwithadigitaltemperatureindicator,withfurnacebui...