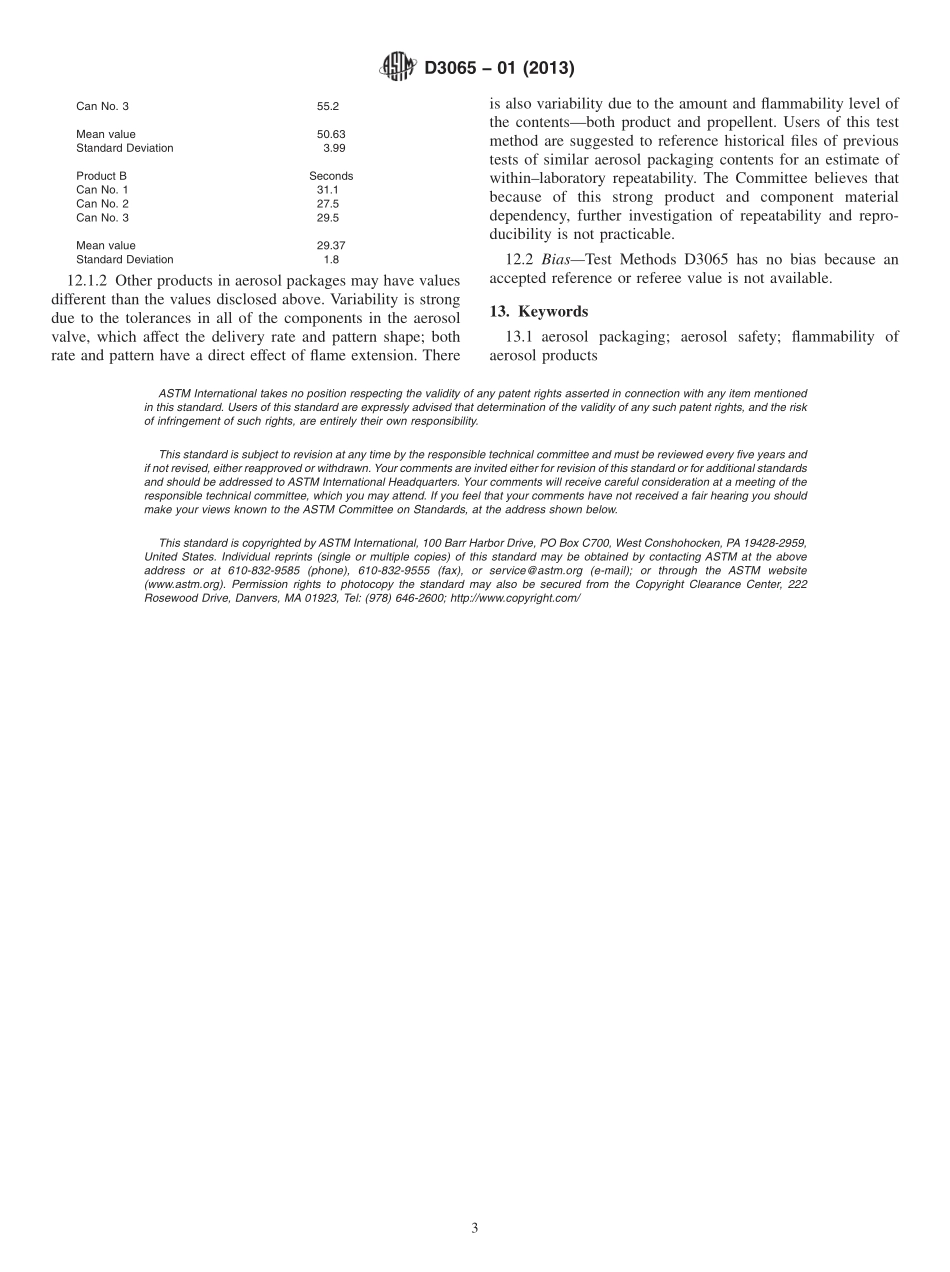

Designation:D3065−01(Reapproved2013)StandardTestMethodsforFlammabilityofAerosolProducts1ThisstandardisissuedunderthefixeddesignationD3065;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thesetestmethodscoverthedeterminationofflamma-bilityhazardsforaerosolproducts.1.2Thesetestmethodsappearinthefollowingorder:SectionFlameProjectionTest4to7ClosedDrumTest8to101.3Thesetestmethodsshouldbeusedtomeasureanddescribethepropertiesofmaterials,products,orassembliesinresponsetoheatandflameundercontrolledlaboratorycondi-tionsandshouldnotbeusedtodescribeorappraisethefirehazardorfireriskofmaterials,products,orassembliesunderactualfireconditions.However,resultsofthistestmaybeusedaselementsofafireriskassessmentwhichtakesintoaccountallofthefactorswhicharepertinenttoanassessmentofthefirehazardofaparticularenduse.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E1SpecificationforASTMLiquid-in-GlassThermometers3.SignificanceandUse3.1ThesetestmethodsweredevelopedsothattheOpenDrumTestcouldbeabandonedasameaningfulguideinestablishingflammabilityhazards.FLAMEPROJECTIONTEST4.Apparatus4.1Base,8in.(203mm)wideand2ft(0.6m)long,markedin6-in.(152-mm)intervals.4.2Rule,2ft(0.6m)long,markedininches(ormillimetres)tobesupportedhorizontallyonthesideofthebaseandapproximately6in.(152mm)aboveit.4.3Candle,paraffin,approximately1in.(25mm)indiam-eterandofsuchheightthatthetopthirdoftheflameisattheheightofthehorizontalrule,tobeplacedatthezeropointinthebase.5.Conditioning5.1Conditionthedispenserto70...