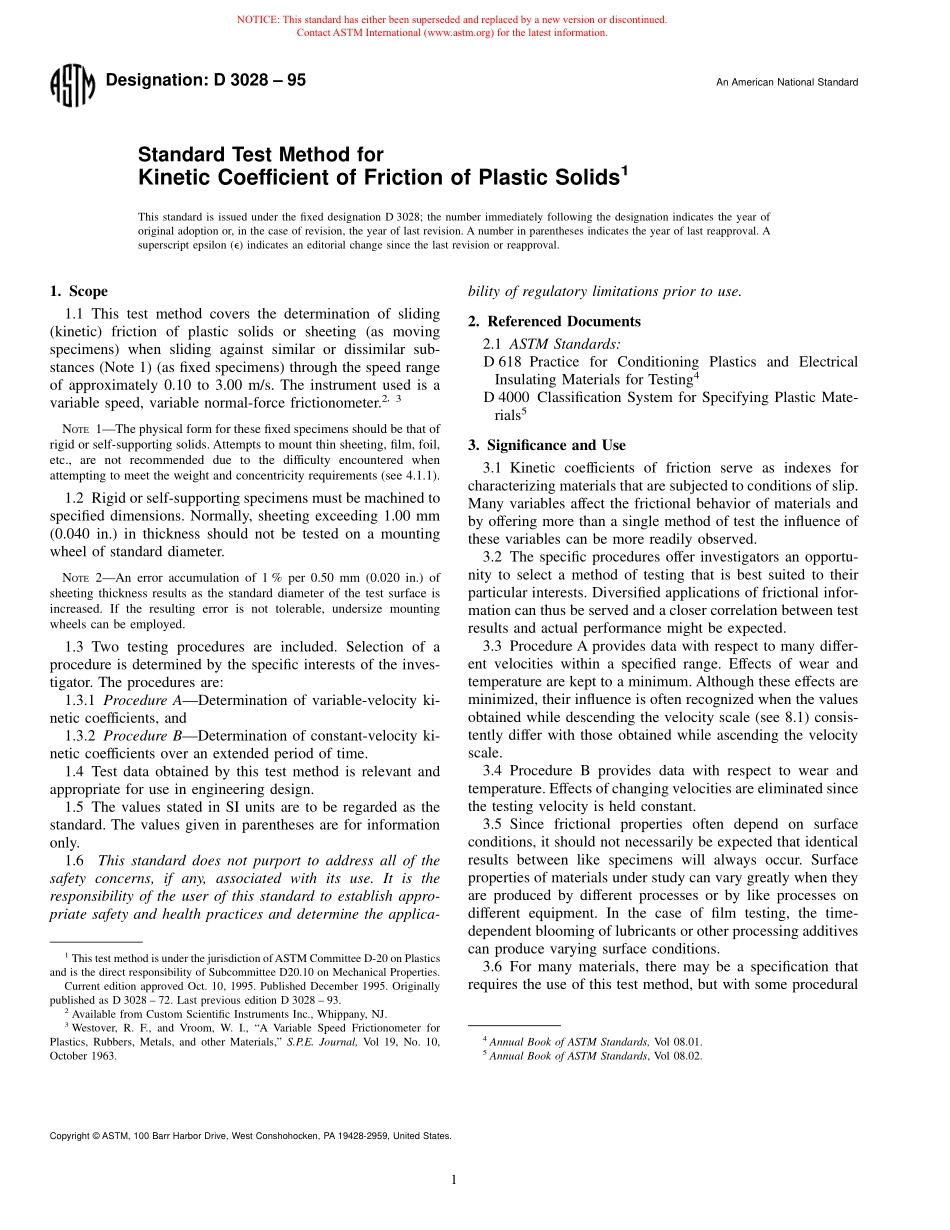

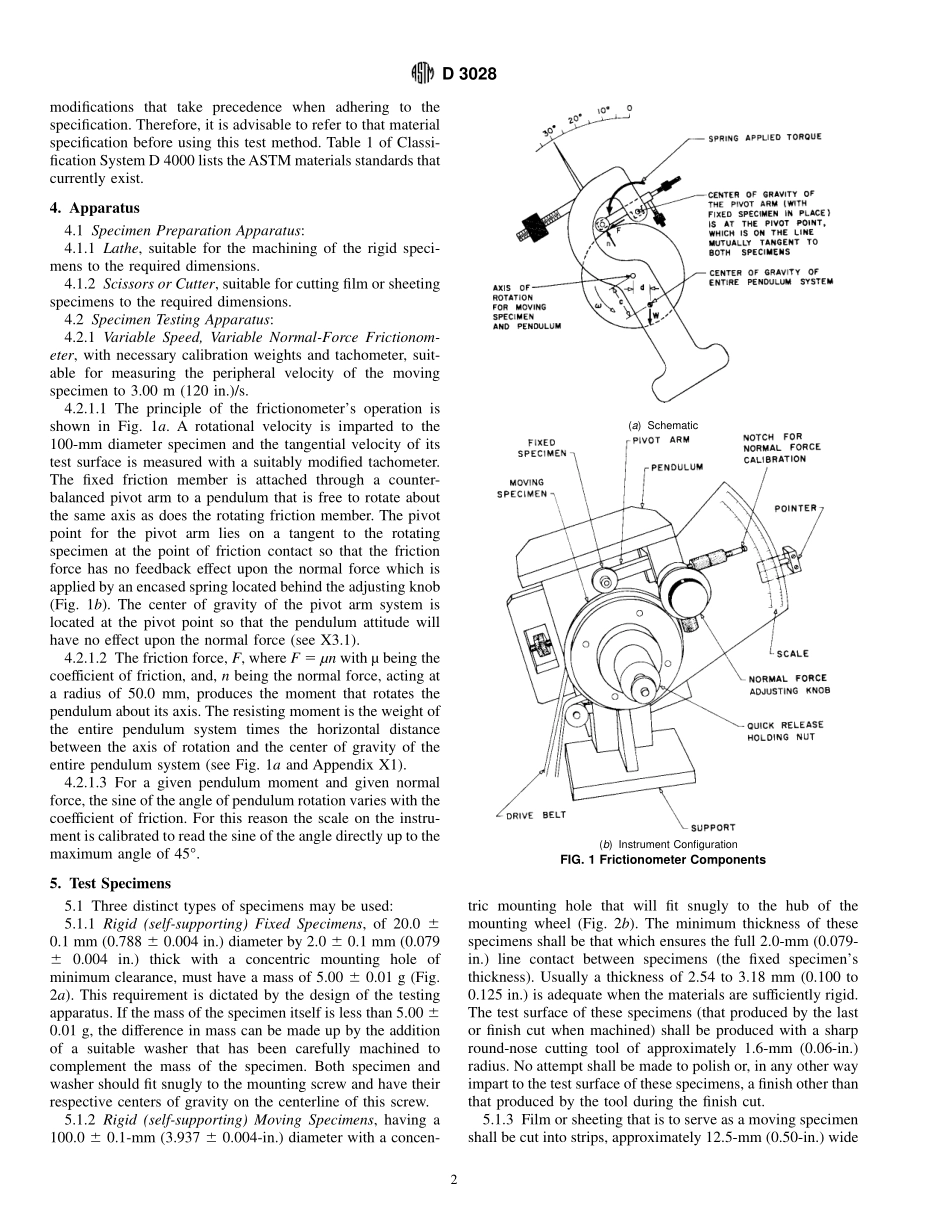

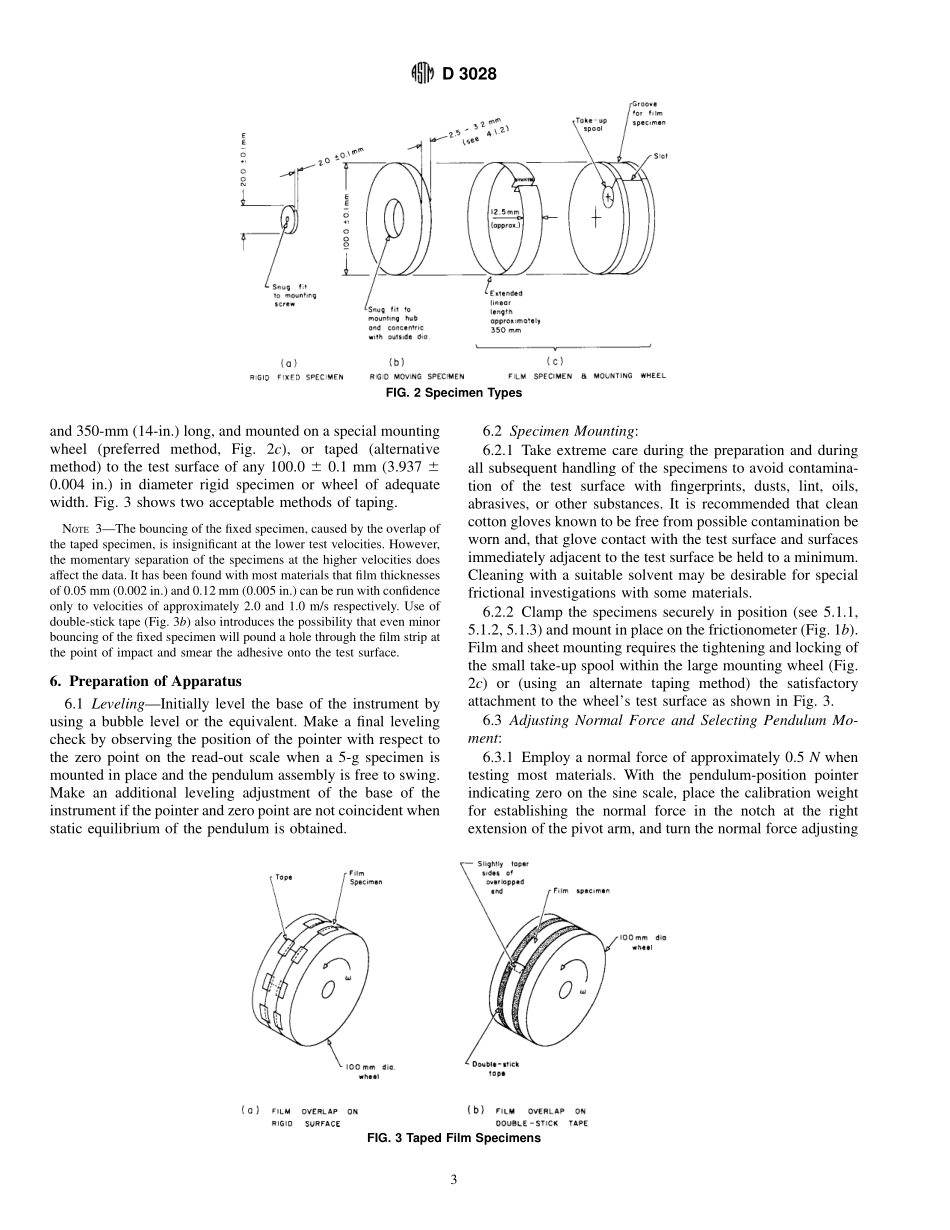

Designation:D3028–95AnAmericanNationalStandardStandardTestMethodforKineticCoefficientofFrictionofPlasticSolids1ThisstandardisissuedunderthefixeddesignationD3028;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofsliding(kinetic)frictionofplasticsolidsorsheeting(asmovingspecimens)whenslidingagainstsimilarordissimilarsub-stances(Note1)(asfixedspecimens)throughthespeedrangeofapproximately0.10to3.00m/s.Theinstrumentusedisavariablespeed,variablenormal-forcefrictionometer.2,3NOTE1—Thephysicalformforthesefixedspecimensshouldbethatofrigidorself-supportingsolids.Attemptstomountthinsheeting,film,foil,etc.,arenotrecommendedduetothedifficultyencounteredwhenattemptingtomeettheweightandconcentricityrequirements(see4.1.1).1.2Rigidorself-supportingspecimensmustbemachinedtospecifieddimensions.Normally,sheetingexceeding1.00mm(0.040in.)inthicknessshouldnotbetestedonamountingwheelofstandarddiameter.NOTE2—Anerroraccumulationof1%per0.50mm(0.020in.)ofsheetingthicknessresultsasthestandarddiameterofthetestsurfaceisincreased.Iftheresultingerrorisnottolerable,undersizemountingwheelscanbeemployed.1.3Twotestingproceduresareincluded.Selectionofaprocedureisdeterminedbythespecificinterestsoftheinves-tigator.Theproceduresare:1.3.1ProcedureA—Determinationofvariable-velocityki-neticcoefficients,and1.3.2ProcedureB—Determinationofconstant-velocityki-neticcoefficientsoveranextendedperiodoftime.1.4Testdataobtainedbythistestmethodisrelevantandappropriateforuseinengineeringdesign.1.5ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.6Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealth...