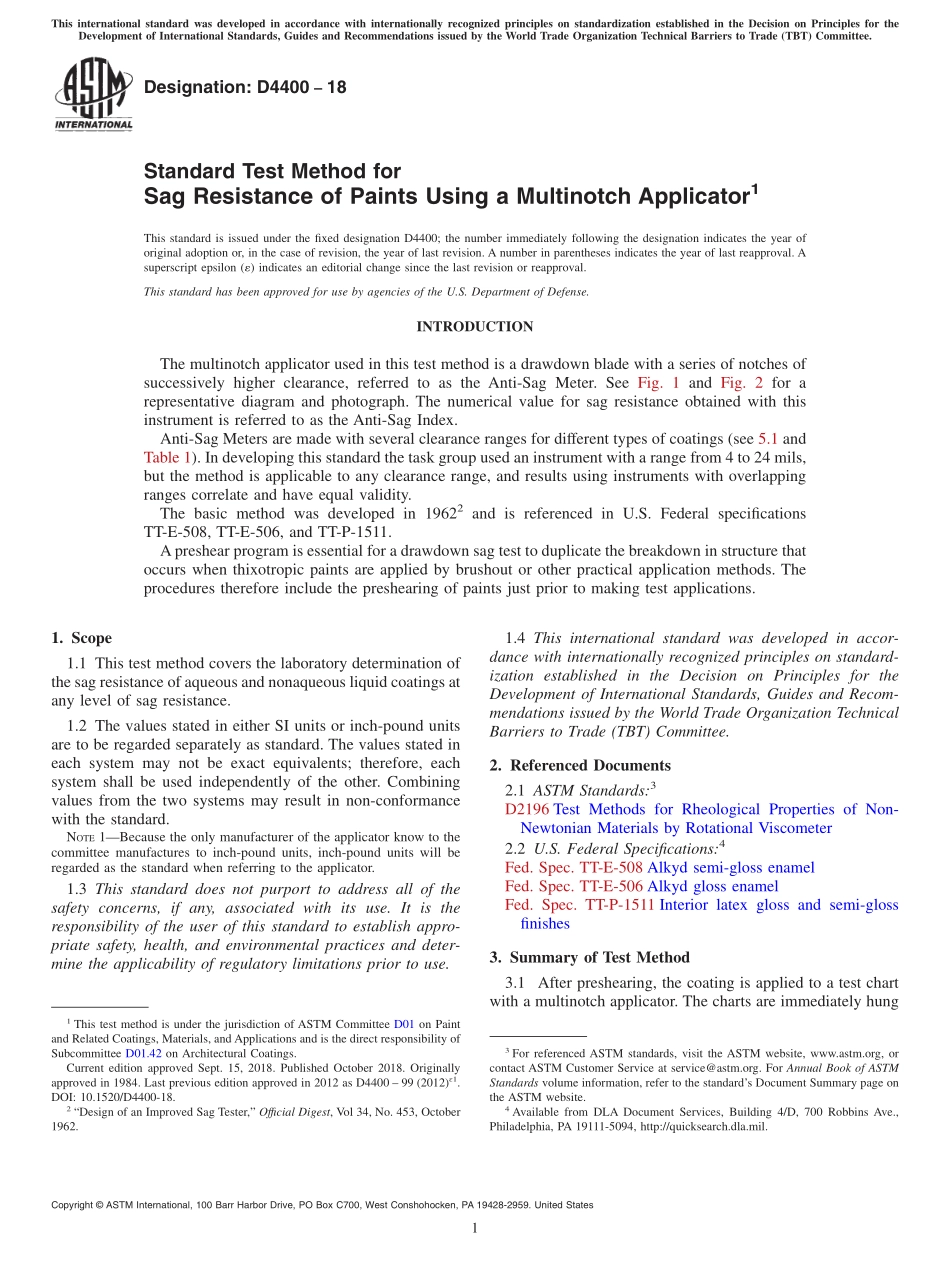

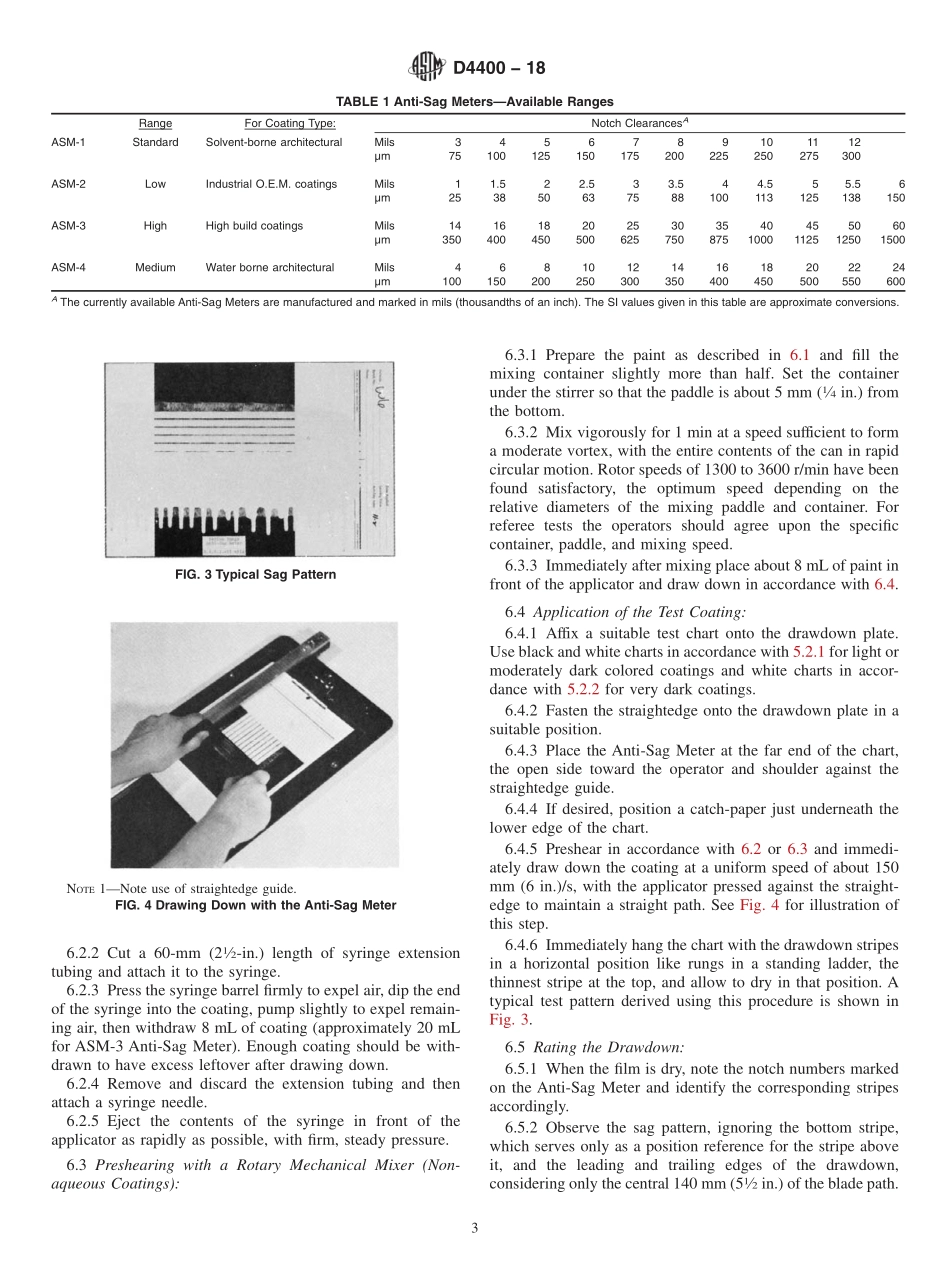

Designation:D4400−18StandardTestMethodforSagResistanceofPaintsUsingaMultinotchApplicator1ThisstandardisissuedunderthefixeddesignationD4400;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.INTRODUCTIONThemultinotchapplicatorusedinthistestmethodisadrawdownbladewithaseriesofnotchesofsuccessivelyhigherclearance,referredtoastheAnti-SagMeter.SeeFig.1andFig.2forarepresentativediagramandphotograph.ThenumericalvalueforsagresistanceobtainedwiththisinstrumentisreferredtoastheAnti-SagIndex.Anti-SagMetersaremadewithseveralclearancerangesfordifferenttypesofcoatings(see5.1andTable1).Indevelopingthisstandardthetaskgroupusedaninstrumentwitharangefrom4to24mils,butthemethodisapplicabletoanyclearancerange,andresultsusinginstrumentswithoverlappingrangescorrelateandhaveequalvalidity.Thebasicmethodwasdevelopedin19622andisreferencedinU.S.FederalspecificationsTT-E-508,TT-E-506,andTT-P-1511.Apreshearprogramisessentialforadrawdownsagtesttoduplicatethebreakdowninstructurethatoccurswhenthixotropicpaintsareappliedbybrushoutorotherpracticalapplicationmethods.Theproceduresthereforeincludethepreshearingofpaintsjustpriortomakingtestapplications.1.Scope1.1Thistestmethodcoversthelaboratorydeterminationofthesagresistanceofaqueousandnonaqueousliquidcoatingsatanylevelofsagresistance.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.NOTE1—Becausetheonlymanufactureroftheapplicatorknowtothecommitteemanufacturestoinch-poundunits,inch-poundunitswillberegardedasthestandardwhenreferringtotheapplicator.1.3Thisstandarddo...