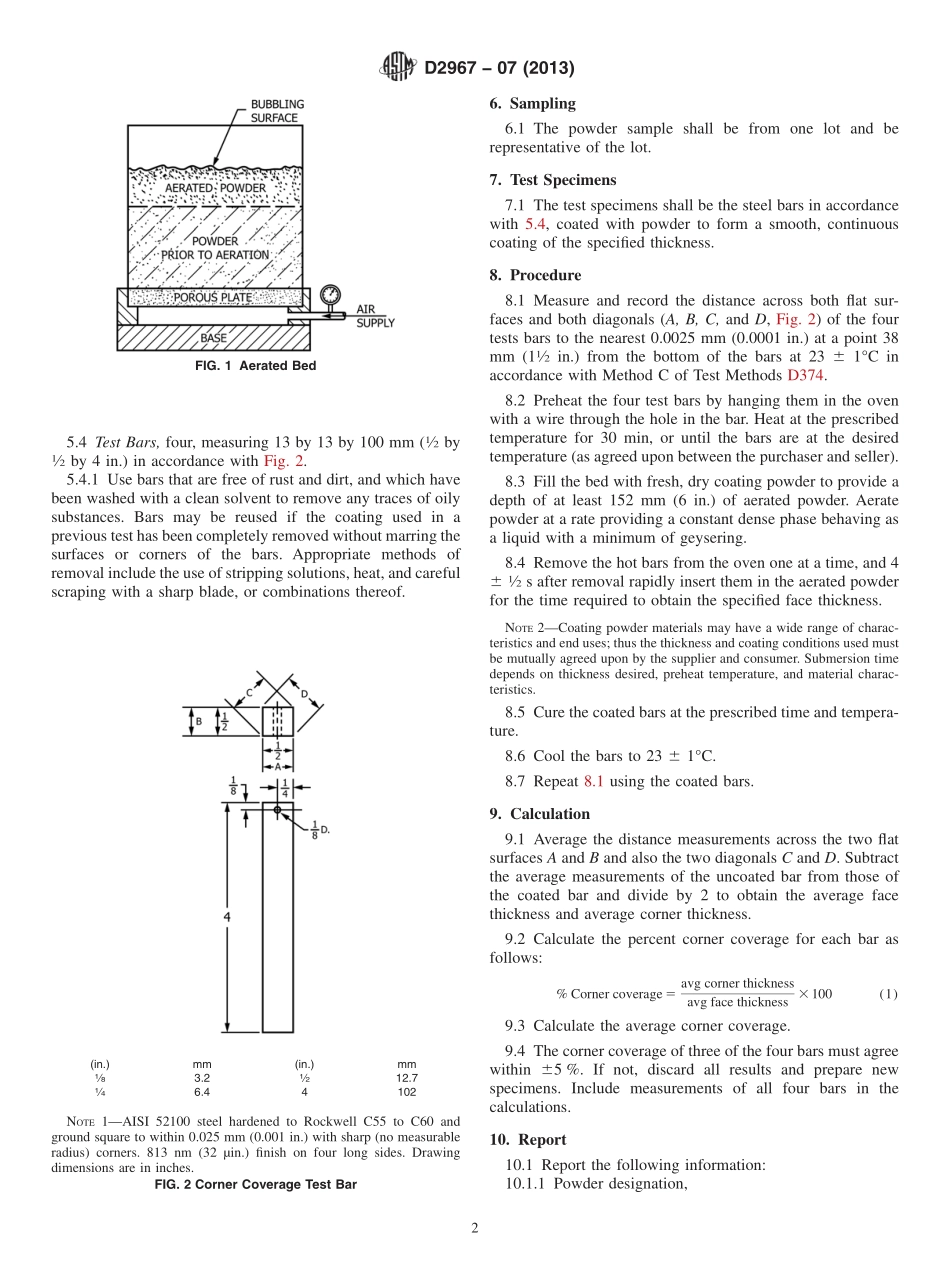

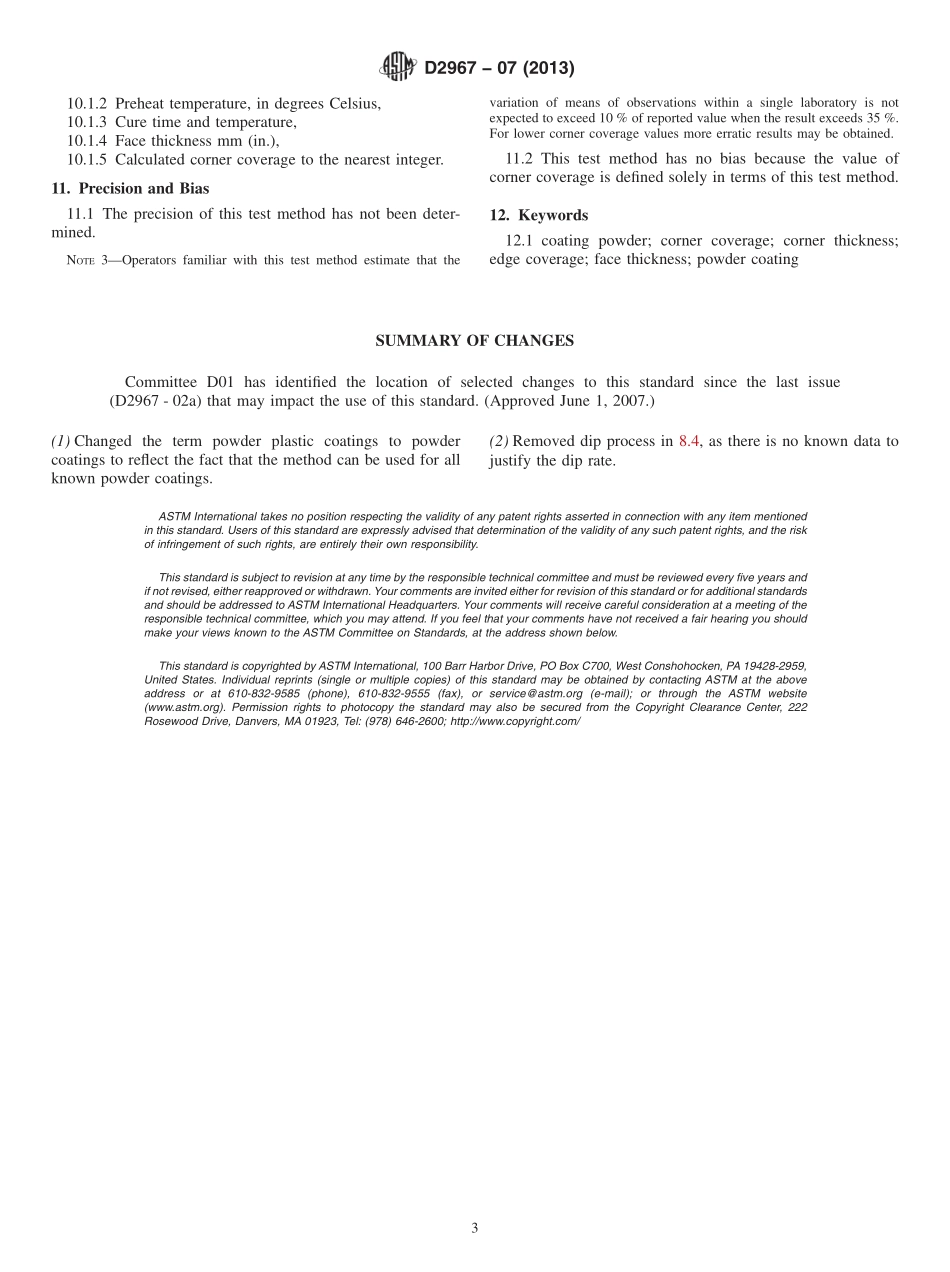

Designation:D2967−07(Reapproved2013)StandardTestMethodforCornerCoverageofPowderCoatings1ThisstandardisissuedunderthefixeddesignationD2967;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversthedeterminationoftheratioofcornerthickness(see3.1.3)tofacethickness(see3.1.4)ofpowdercoatingsappliedtoaspecificfacethicknessbydippingpreheatedsquarebarsintoaeratedpowderandcuringthecoatingusingpredeterminedconditions.NOTE1—Thepropertyofcornercoveragehasalsobeenreferredtoas“edgecoverage,”thoughthelatterisnotrecommended.Therearewidespreadmisunderstandingsandexpectationsrelativetotheterm“edgecoverage.”Thistestisperformedonasteelbarhavingsquarecornersandtheresultsdonotnecessarilyrelatetoedgesthataresharper,thatis,burrs.Acoatingthathasmeasurablecornercoveragemaystillnotprotectsharperedgesfromcorrosionorprovidetheelectricalinsulationneededinsomeapplications.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D374TestMethodsforThicknessofSolidElectricalInsu-lation(Withdrawn2013)33.Terminology3.1Definitions:3.1.1coatingpowders,n—finelydividedparticlesofresin,eitherthermoplasticorthermosetting,generallyincorporatingpigments,fillers,andadditivesandremainingfinelydividedduringstorageundersuitableconditions,which,afterfusingandpossiblycuring,giveacontinuousfilm.3.1.1.1Discussion—Thecoatingpowdermaycontainfillers,colorants,curingagents,etc.,consistentwithproducingthedesiredcoatings.Thepowderisappliedbyvariousmethodssuchas...