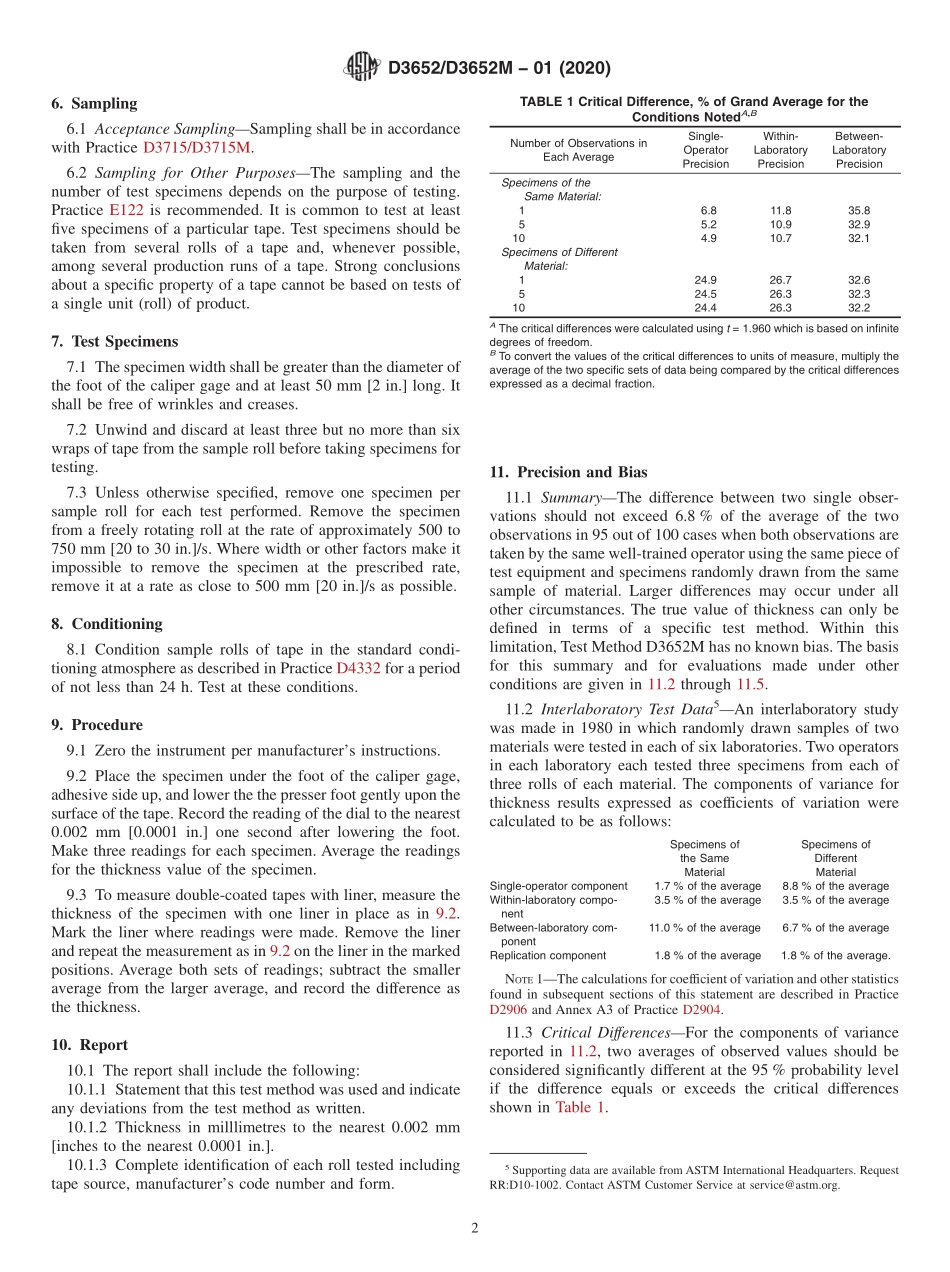

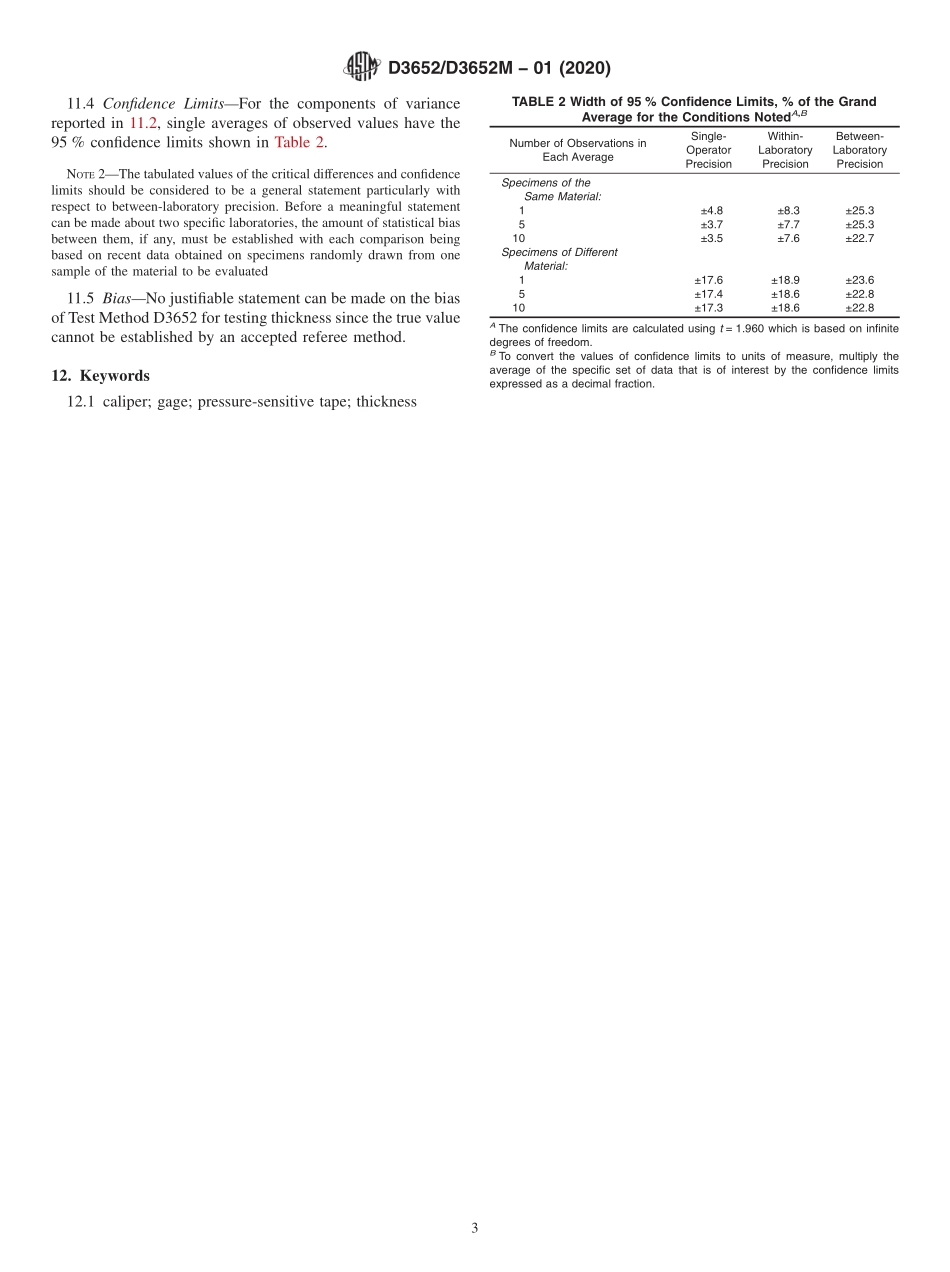

Designation:D3652/D3652M−01(Reapproved2020)StandardTestMethodforThicknessofPressure-SensitiveTapes1ThisstandardisissuedunderthefixeddesignationD3652/D3652M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationofthethick-nessofpressure-sensitivetapesatstandardconditions.1.2ThistestmethodisintendedtoreplaceAFERA40062andPSTC33.21.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:3D996TerminologyofPackagingandDistributionEnviron-mentsD2904PracticeforInterlaboratoryTestingofaTextileTestMethodthatProducesNormallyDistributedData(With-drawn2008)4D2906PracticeforStatementsonPrecisionandBiasforTextiles(Withdrawn2008)4D3715/D3715MPracticeforQualityAssuranceofPressure-SensitiveTapesD4332PracticeforConditioningContainers,Packages,orPackagingComponentsforTestingE122PracticeforCalculatingSampleSizetoEstimate,WithSpecifiedPrecision,theAverageforaCharacteristicofaLotorProcess3.Termin...