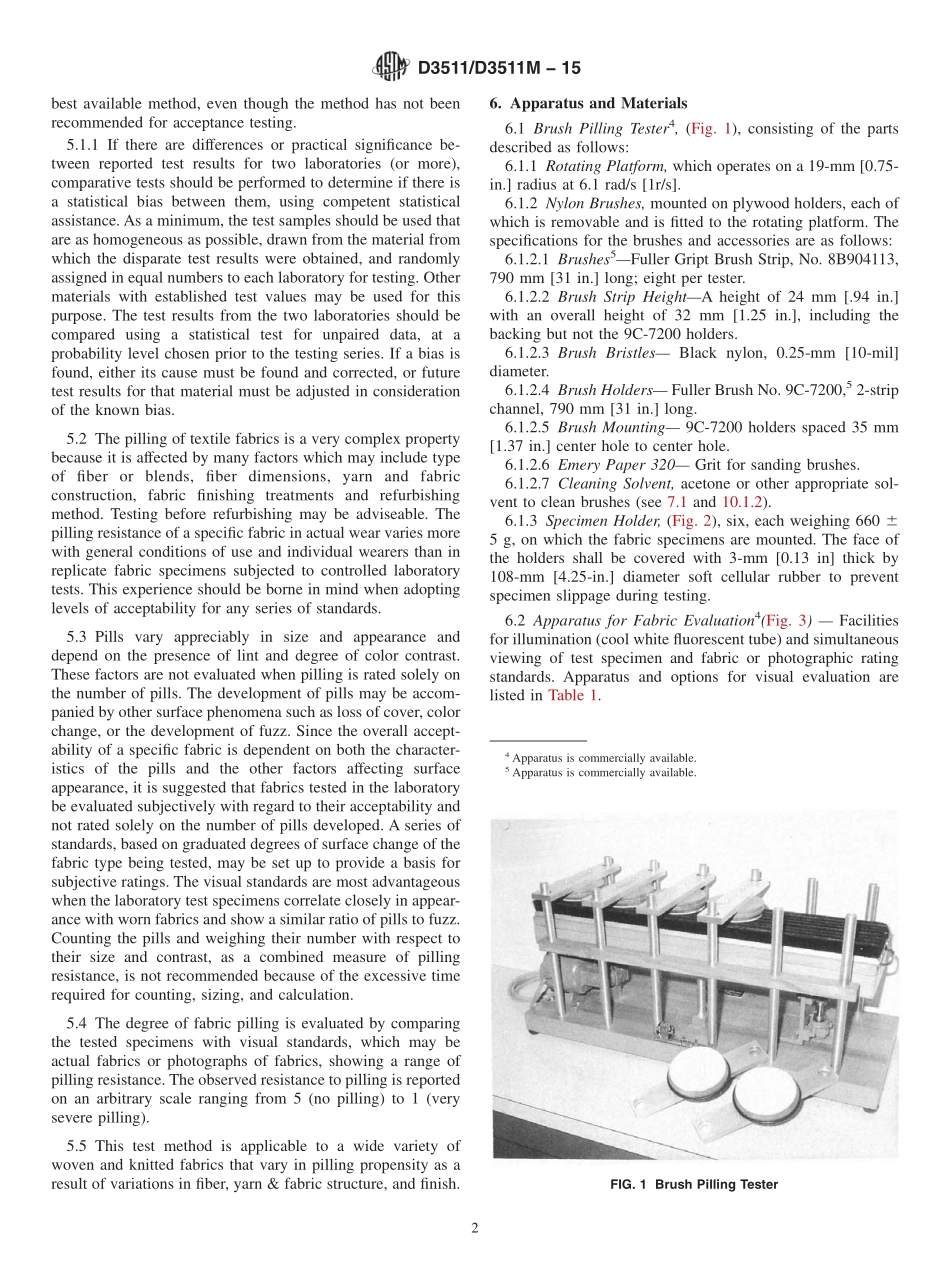

Designation:D3511/D3511M−15StandardTestMethodforPillingResistanceandOtherRelatedSurfaceChangesofTextileFabrics:BrushPillingTester1ThisstandardisissuedunderthefixeddesignationD3511/D3511M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationofthepro-pensityofafabrictoformpillsfromfuzzundertestconditionsintendedtosimulatenormalwearusingthebrushpillingtester.Thisprocedureisgenerallyintendedtobeusedforupholstery,automotive,luggageandheavydutyuniformfabricsbecauseitishighlyabrasive.Thisdoesnothoweverprecludeitfrombeingusedforothertypesoffabrics.Ifunsure,comparisontestsshouldbeperformedtoensurethatthistestmethodreplicatespillingonthefinalproduct.NOTE1—Forothertestmethodsforthepillingresistanceoftextiles,refertoTestMethodsD3512,D3514,andD4970.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D123TerminologyRelatingtoTextilesD1776PracticeforConditioningandTestingTextilesD3512TestMethodforPillingResistanceandOtherRelatedSurfaceChangesofTextileFabrics:RandomTumblePillingTesterD3514TestMethodforPillingResistanceandOtherRelatedSurfaceChangesofTextileFabrics:ElastomericPadD4850TerminologyRelatingtoFabricsandFabricTestMethodsD4970TestMethodforPillingResistanceandOtherRel...