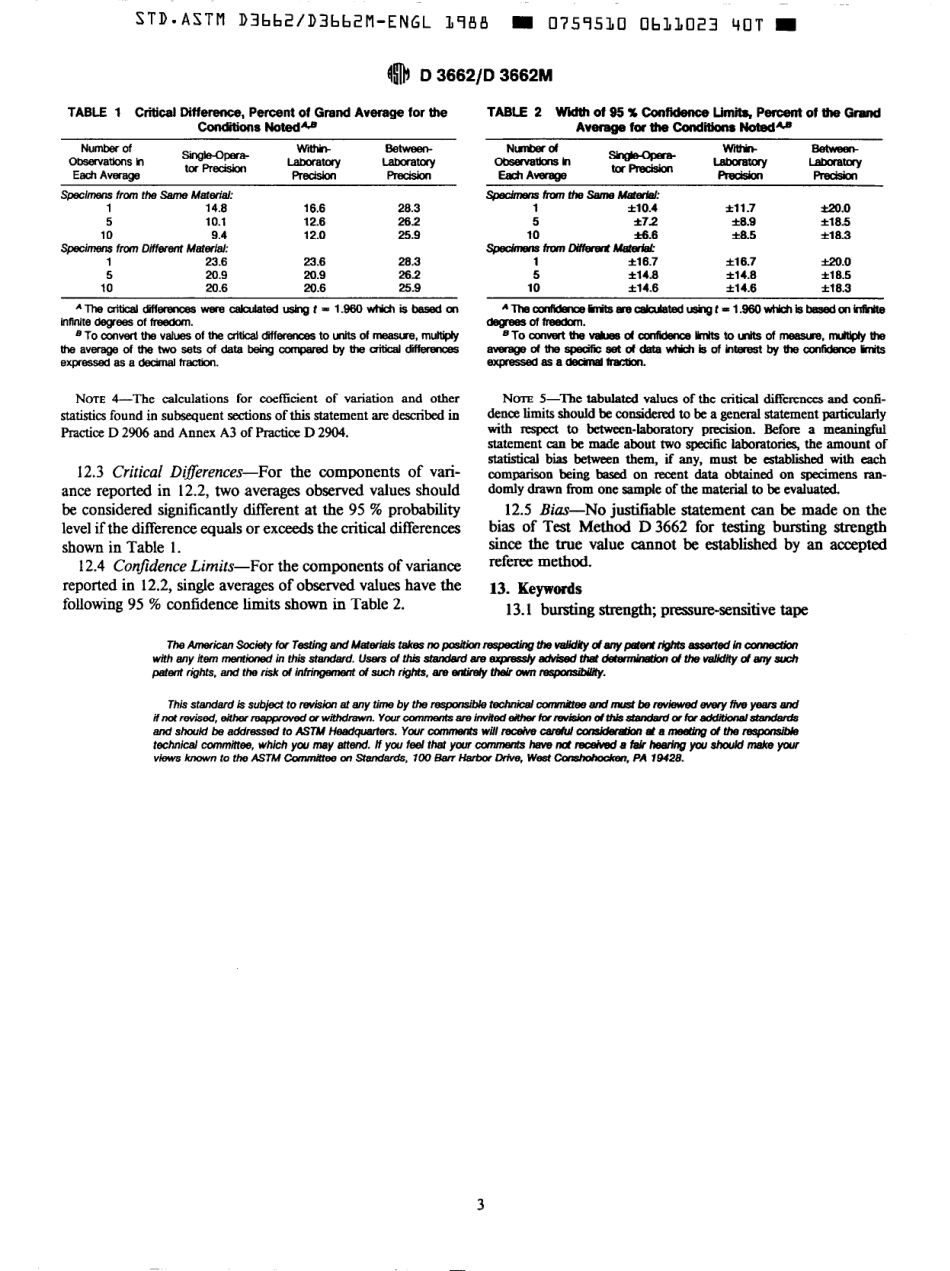

STD.ASTMD3662/D3662M-ENGLI,988-0759530ObLLO2L637=Designation:D3662/D3662M-88(Reapproved1993)c2AMERICANSOCIETYFORTESTINGANDMATERIALS100BarrHarborOr..WestConshohocken.PA19428RepnntedfromtheAnnualBookofASTMStandards.CopyrightASTMStandardTestMethodforBurstingStrengthofPressure-SensitiveTapes’‘hisstandardisissuadunderthefixeddaipationD3662/D3662M,thenumberimmehtelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,thcyearoflastrevision.Anumbcrinparrntbesesindicatcsthcyearoflartreapproval.Asuperscriptepsilon(e)indicatesaneditorial&au&sin@tbela%trevisionorrespprovaLThisstan&udhasbeenappmvedforusebyagenci~oftheDqwtmeniqfD&me.%iikedon13wasaddededitoriallyinJuly1993.c*NUTE-D3662andD3662MweremmbinededitmiaUyinDecember1997.1.Scope1.1Thistestmethodcoversthemeasurementoftheburstingstrengthofpressure-sensitivetapeusedintheclosureoffiberboardcontainers.1.2ThevaluesstatedineitherSIorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemmustbeusedindependently,withoutcombiningvaluesinanyway.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.ItistheresponsibilityoftheuserofthisstandardtoestablishapprcFpriatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D996TerminologyofPackagingandDistributionEnvironments2D2529TestMethodforBurstingStrengthofPaperboardandLinerboardD2904PracticeforInterlabomtoryTestingofaTextileTestMethodthatProducesNormallyDistributedData4D2906PracticeforStatementsonPrecisionandBiasforTextiles4D3715/D3715MPracticeforQualityAssuranceofPres-sure-SensitiveTapes2D4332PracticeforConditioningContainers,Packages,orPackagingComponentsforTesting2E122PracticeforChoiceofSampleSizetoEstimateaMeasureofQualityforaLotorProcess53.Terminology3.1TerminologyfoundinTerminologyD996shallapply.’ThistestmethodisunderthejurisdictionofASfMCommitteeD-10onPackagingandisthedirectre...