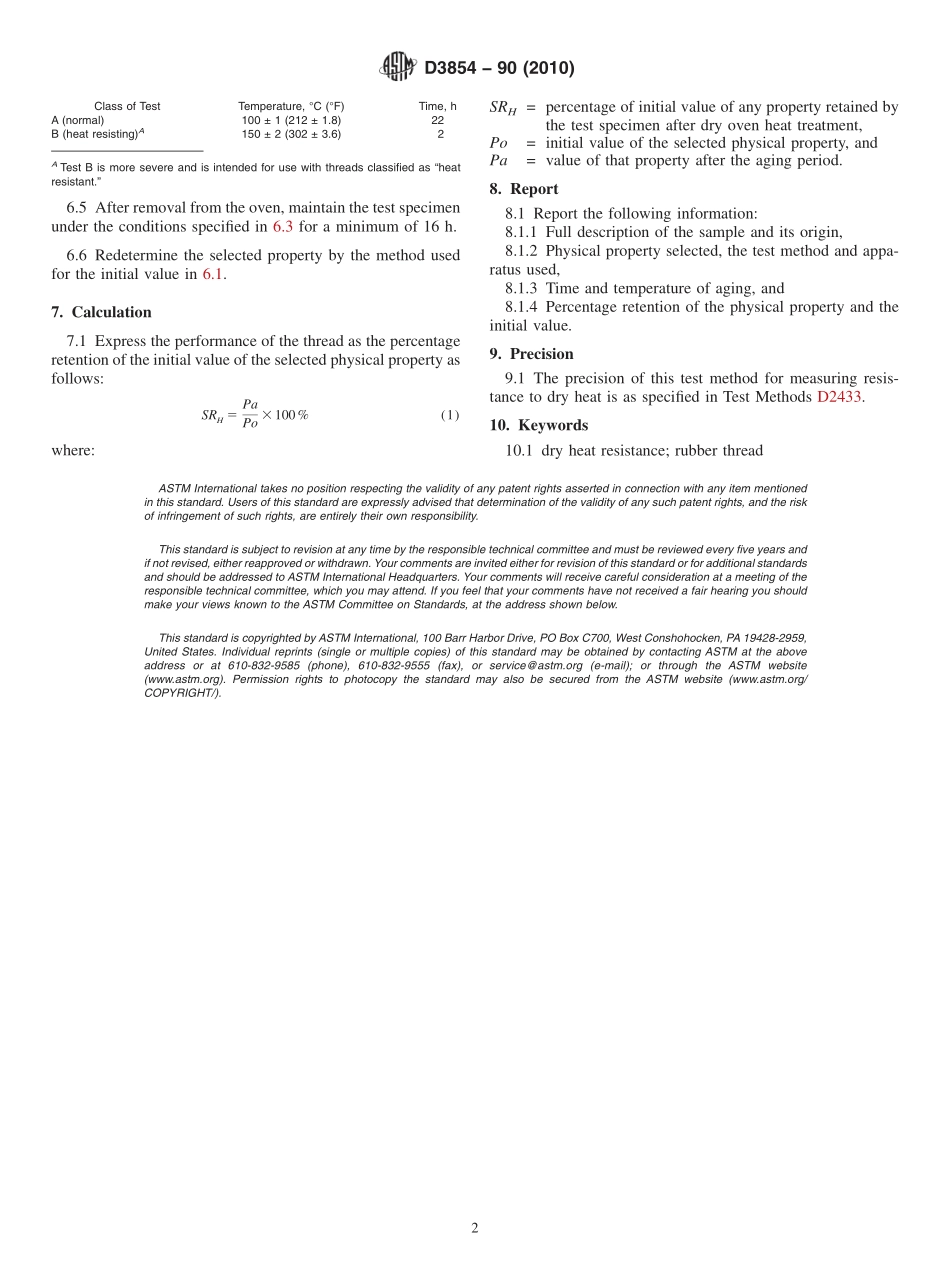

Designation:D3854−90(Reapproved2010)StandardTestMethodforRubberThread—ResistancetoDryHeat1ThisstandardisissuedunderthefixeddesignationD3854;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoverstheextentofdeteriorationofrubberthreadsbymeasuringthereductioninphysicalproper-tieswhenathreadismaintainedataconstantelongationunderconditionsmoreseverethanthoseencounteredinservice.Thistestmethodisacomparativeindicationonly;itmaynotbepossibletocorrelatetheresultswiththeactualdurationoflifeinservice.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesinparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D1349PracticeforRubber—StandardTemperaturesforTestingD2433TestMethodsforRubberThread(Withdrawn2012)3E145SpecificationforGravity-ConvectionandForced-VentilationOvens3.SummaryofTestMethod3.1Theinitialphysicalpropertiesofthethreadaredeter-minedbytheappropriatetestmethodinaccordancewithTestMethodsD2433.Thesametestpieces,maintainedat100%elongation,aresubjectedtoaginginacirculatingairoven.Theresidualphysicalpropertiesarethenmeasuredandthepercent-agechangereported.3.2ThephysicalpropertymeasuredinthetestmaybeanyofthosedescribedinSections18to37ofTestMethodsD2433;however,themostsuitablearetheSchwartzvalue(Section23)orstressretention(Section33).4.SignificanceandUse4.1Conventionalrubberagingteststhatarenormallycar-riedoutonunstretchedtestspecimensareoflimiteduseinassessingthelifeofrubberthreadssincetheseareusuallykeptextendedinuse.5.Apparatus5.1Suitabletestapparatusforthemeasurementof...