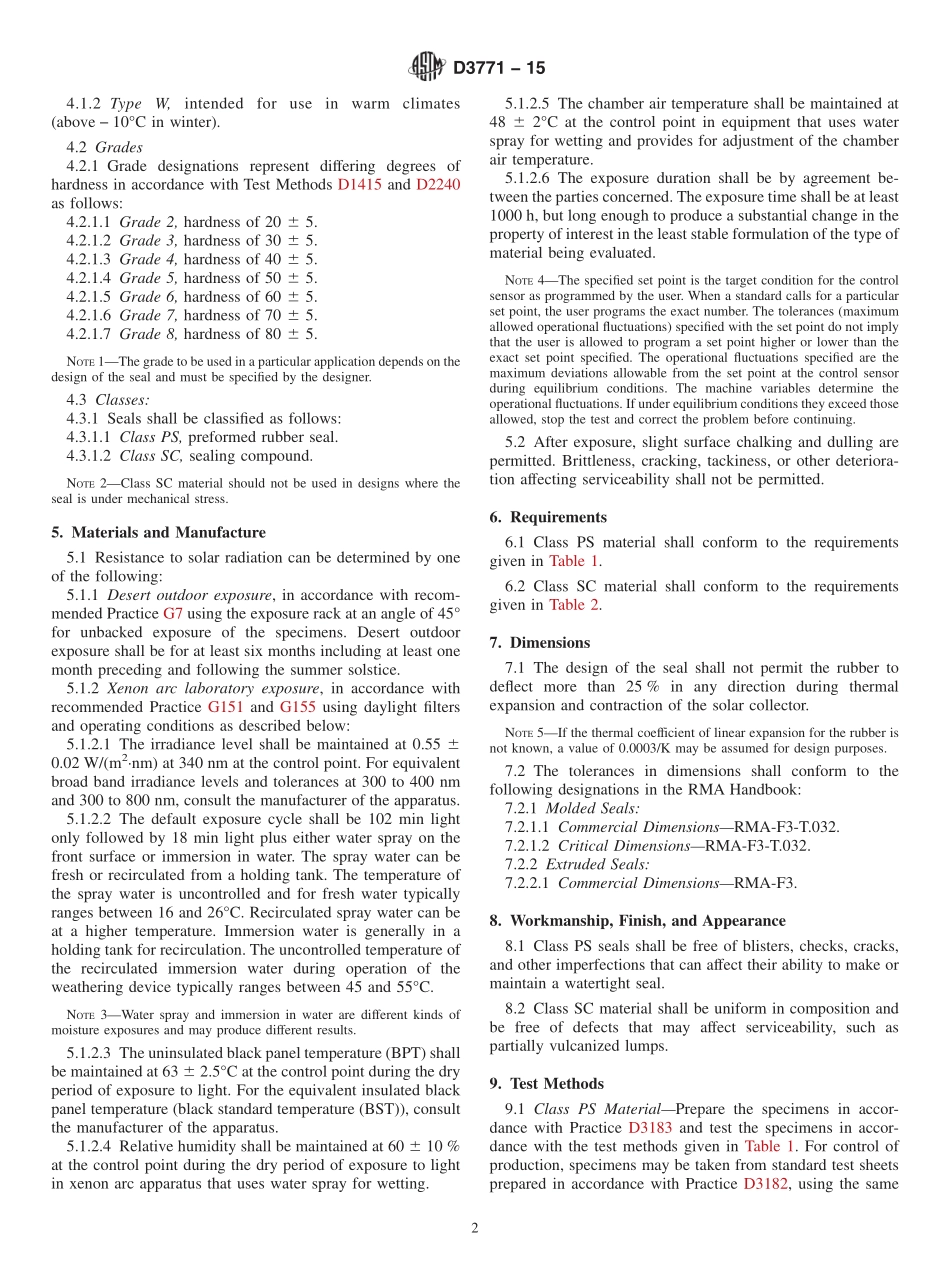

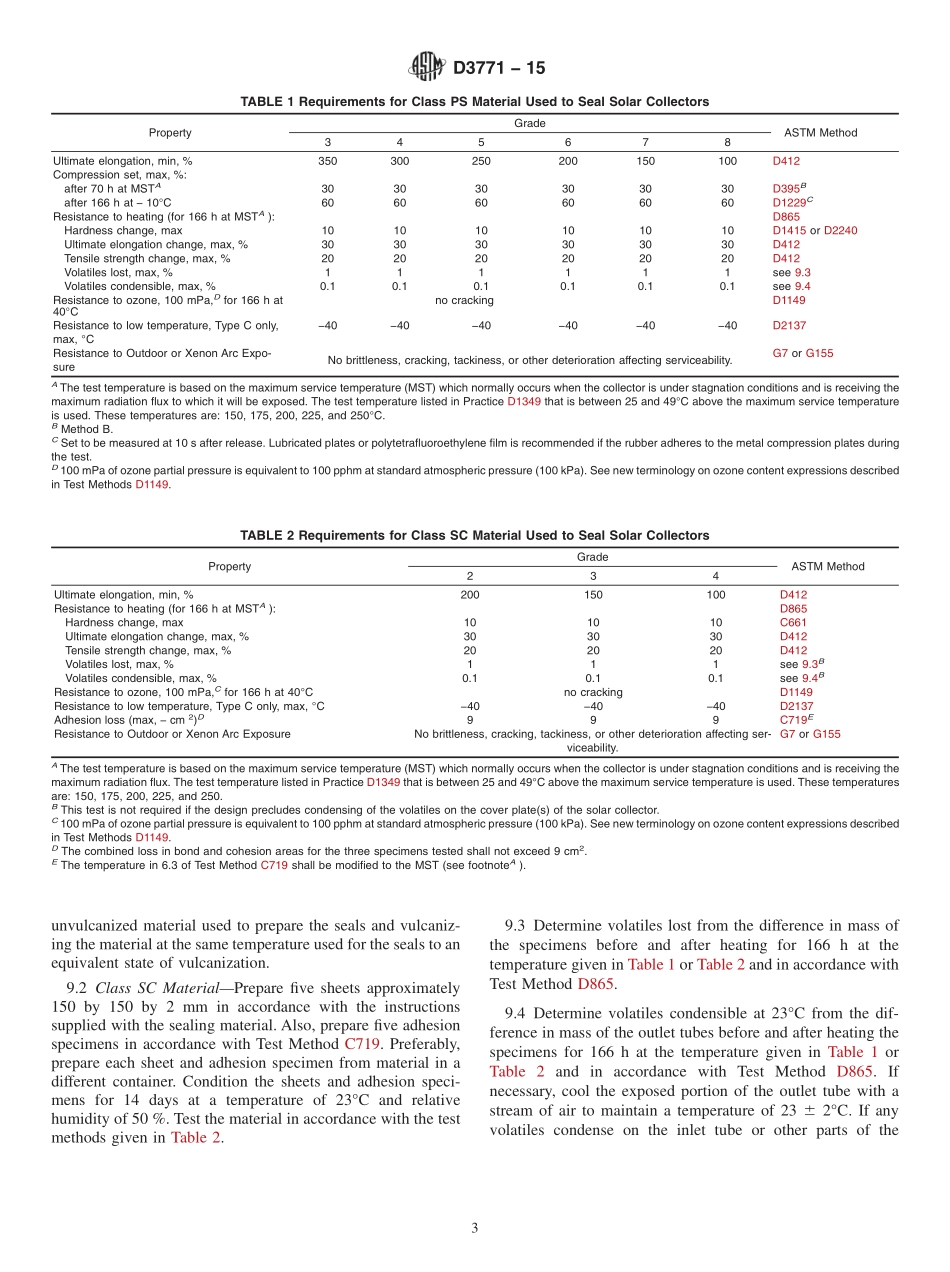

Designation:D3771−15StandardSpecificationforRubberSealsUsedinConcentratingSolarCollectors1ThisstandardisissuedunderthefixeddesignationD3771;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversthegeneralrequirementsformaterialsusedinrubbersealsofconcentratingsolarcollectors.Particularapplicationsmaynecessitateotherrequirementsthatwouldtakeprecedenceovertheserequirementswhenspeci-fied.1.2Designrequirementpertainsonlytopermissibledeflec-tionsoftherubberduringthermalexpansionorcontractionofthesealinuseandthetolerancesindimensionsofmoldedandextrudedseals.1.3Thisspecificationdoesnotincluderequirementsper-tainingtothefabricationorinstallationoftheseals.1.4ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.5Thefollowingsafetyhazardscaveatpertainsonlytothetestmethodsportion,Section9,ofthisspecification:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2C661TestMethodforIndentationHardnessofElastomeric-TypeSealantsbyMeansofaDurometerC717TerminologyofBuildingSealsandSealantsC719TestMethodforAdhesionandCohesionofElasto-mericJointSealantsUnderCyclicMovement(HockmanCycle)D395TestMethodsforRubberProperty—CompressionSetD412TestMethodsforVulcanizedRubberandThermoplas-ticElastomers—TensionD865TestMethodforRubber—DeteriorationbyHeatinginAir(TestTubeEnclosure)D1149TestMethodsforRubberDeterioration—CrackinginanOzoneControlledEnvironmentD1229TestMethodforRubberProperty—CompressionSetatLowTemperaturesD1349PracticeforRubber—StandardConditionsforTest-ingD1415TestMethodforRub...