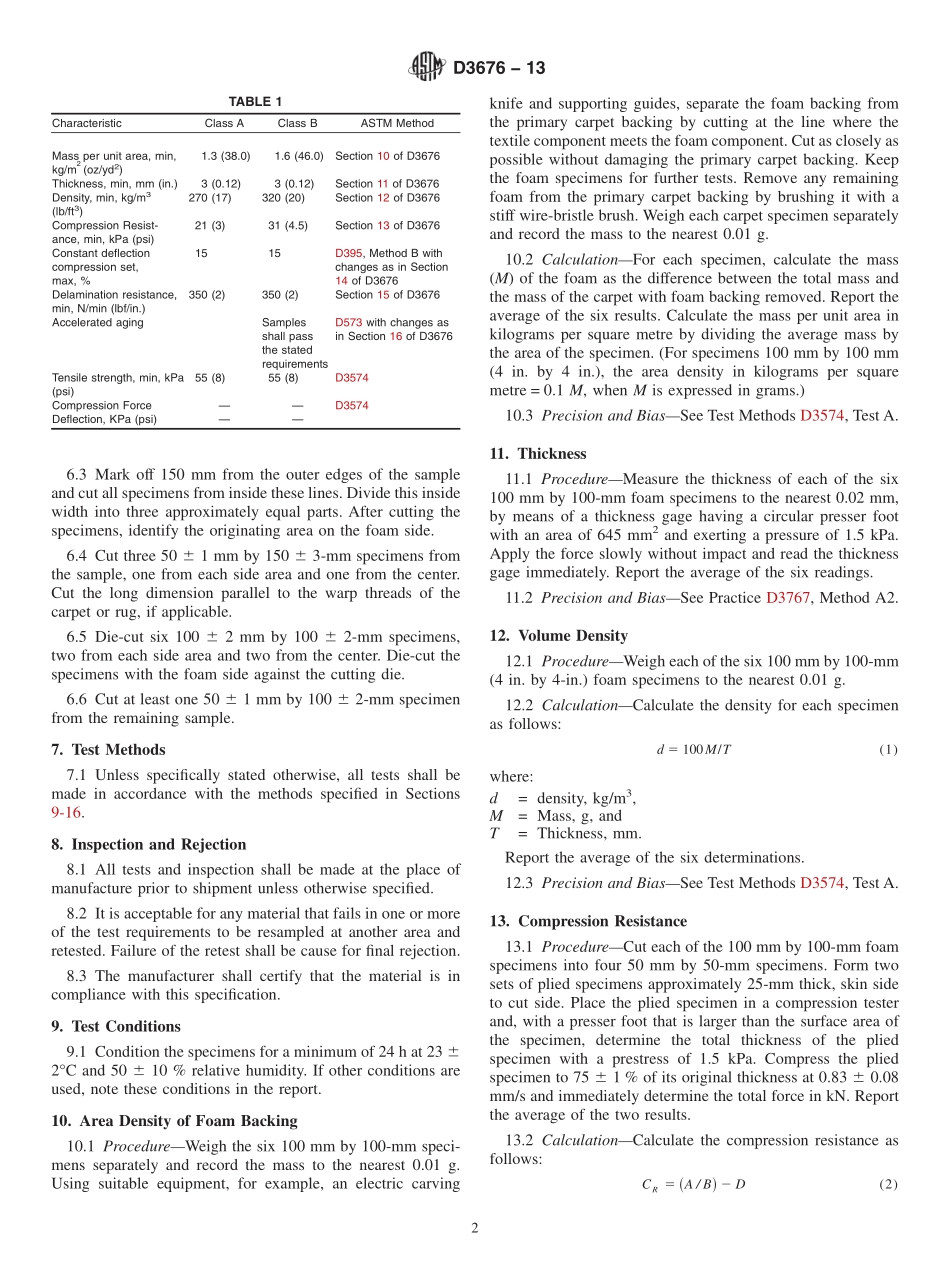

Designation:D3676−13StandardSpecificationforRubberCellularCushionUsedforCarpetorRugUnderlay1ThisstandardisissuedunderthefixeddesignationD3676;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcovershigh-densitycellularrubberadheredtocarpet,rugs,orvarioussubstratesforuseasseparateunderlay.Itisalsoacceptabletousethisstandardasaspecificationforseparatelyblownspongeusedascarpetunderlay.1.2Thisspecificationprovidesmaterialanddimensionalrequirementsandtestmethodsforspecificpropertiesofcom-pressionset,compressionresistanceorcompressionforcedeflection,delaminationstrength,andacceleratedaging.NOTE1—Thisspecificationdoesnotincluderequirementsforburningcharacteristics.ItshallbenotedthatFlammableFabricsActRegulationsFF1-70,StandardfortheSurfaceFlammabilityofCarpetsandRugs,andFF2-70,StandardfortheSurfaceFlammabilityofSmallCarpetsandRugs,2maybeapplicableforcarpetsandrugswithintegralbackingofrubbercellularcushion.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE2—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:3D395TestMethodsforRubberProperty—CompressionSetD573TestMethodforRubber—DeteriorationinanAirOvenD751TestMethodsforCoatedFabricsD1056SpecificationforFlexibleCellularMaterials—SpongeorExpandedRubberD3574TestMethodsforFlexibleCellularMaterials—Slab,Bonded,andMoldedUrethaneFoamsD3767PracticeforRubber—MeasurementofDimensions2.2FederalStandard:Fed.Std.No.191TextileTestMethods,Method5100—BreakingStrengthandElongationofWovenCloth;GrabMethod43.SignificanceandUse3.1Thepurposeofthisspecificationistoprovidemeaning-fulte...