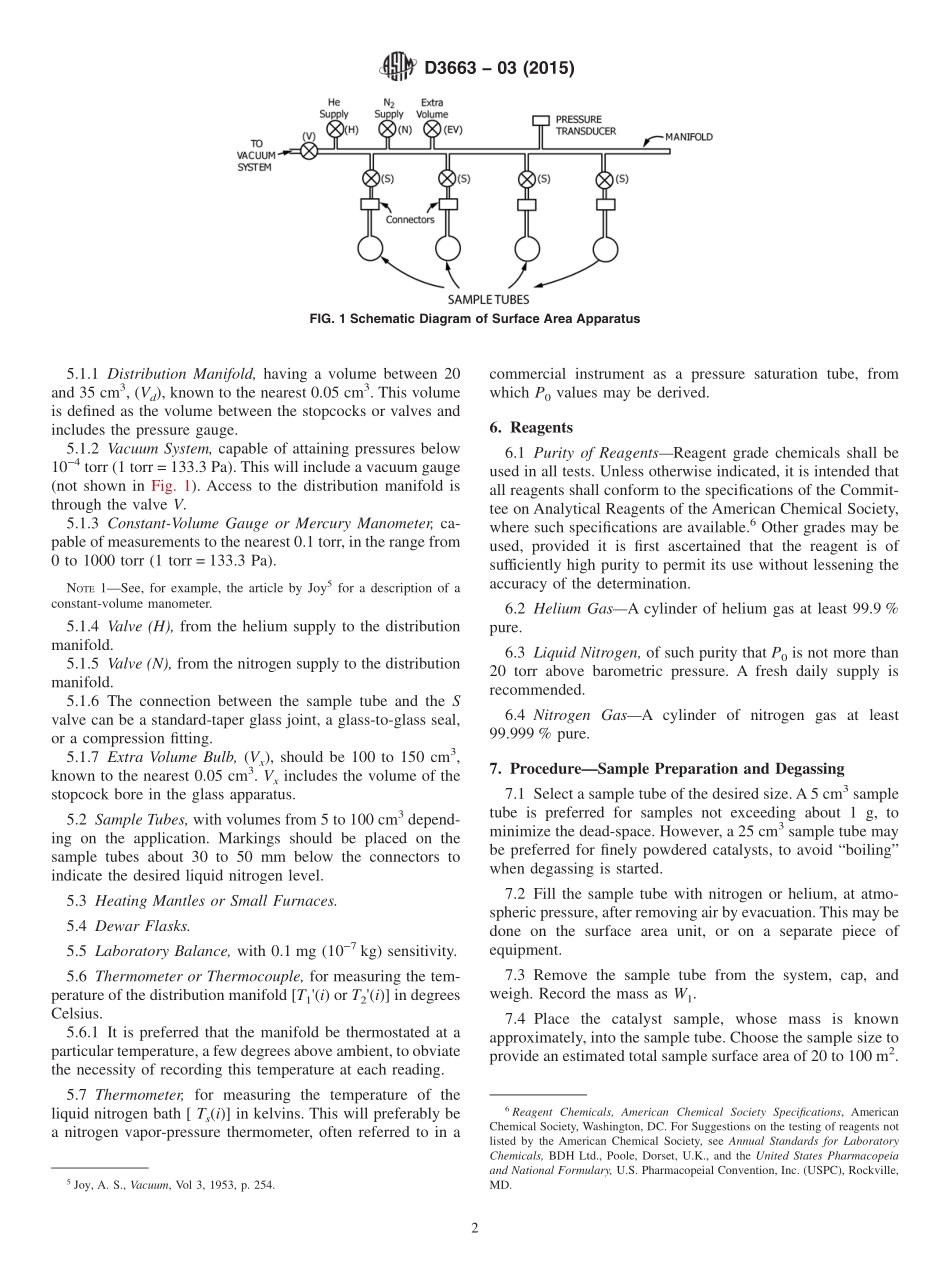

Designation:D3663−03(Reapproved2015)StandardTestMethodforSurfaceAreaofCatalystsandCatalystCarriers1ThisstandardisissuedunderthefixeddesignationD3663;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1ThistestmethodcoversthedeterminationofsurfaceareasofcatalystandcatalystcarriersthathaveTypeIIorIVnitrogenadsorptionisotherms,andatleast1m2/gofarea.AvolumetricmeasuringsystemisusedtoobtainatleastfourdatapointswhichfitonthelinearBET2equationline.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:3D3766TerminologyRelatingtoCatalystsandCatalysisE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE456TerminologyRelatingtoQualityandStatisticsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1ConsultTerminologyD3766fordefinitionsofothertermsused.3.2Definitions:3.2.1surfaceareaofacatalyst—thetotalsurfaceofthecatalyst.Itisexpressedinsquaremetrespergram.3.3Symbols:PH1=initialheliumpressure,torrPH2=heliumpressureafterequilibration,torrTH1=temperatureofmanifoldatinitialheliumpressure,°CTH2=temperatureofmanifoldafterequilibration,°CP1=initialN2pressure,torrT1=manifoldtemperatureatinitialN2pressure,KT1'=manifoldtemperatureatinitialN2pressure,°CP2=pressureafterequilibration,torrP0=liquidnitrogenvaporpressure,torrTs=liquidnitrogentemperature,KX=relativepressure,P2/P0Vd=volumeofmanifold,cm3Vx=extravolumebulb,cm3Vs=dead-spacevolume,cm3Ws=massofsample,gW1=taremassofsampletube,gW2=sampl...