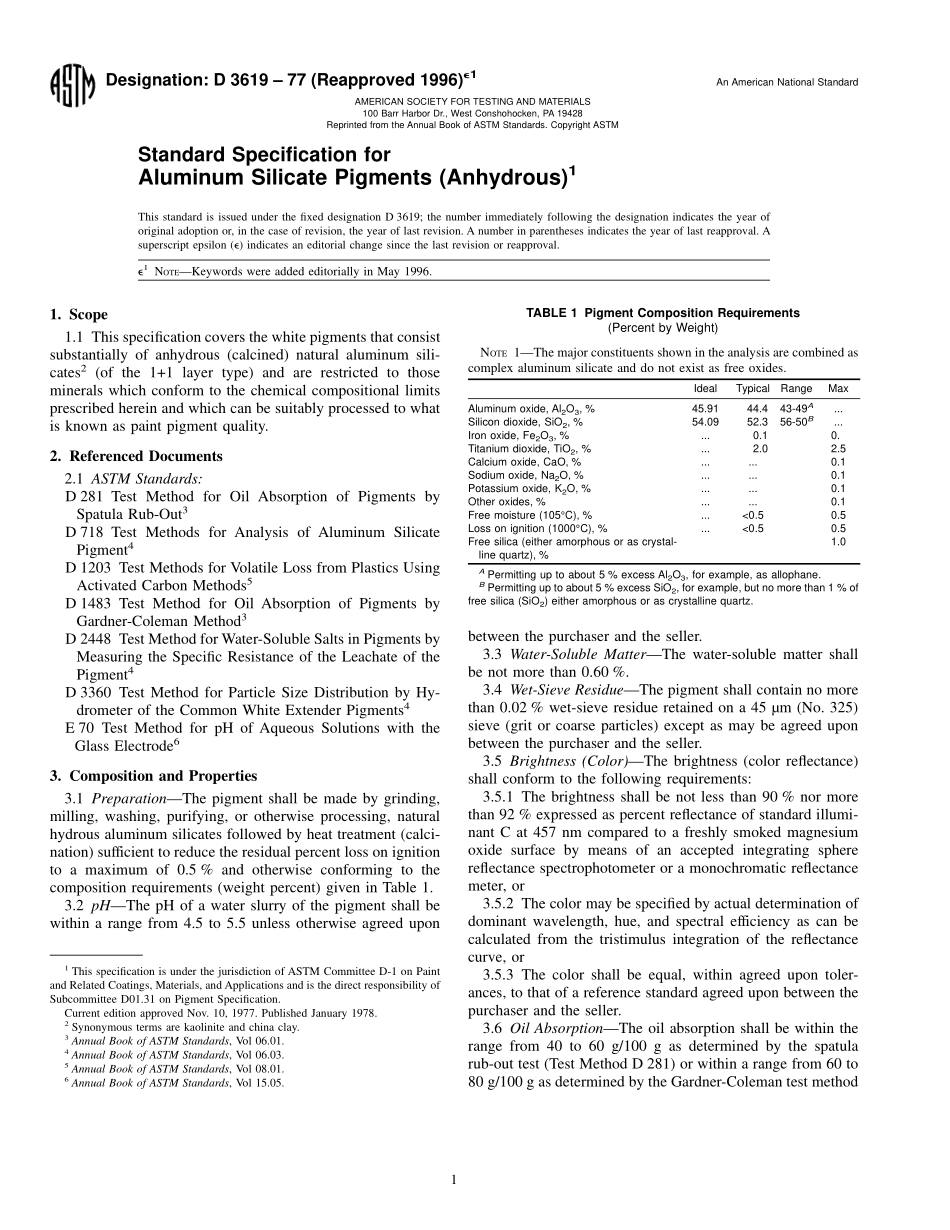

Designation:D3619–77(Reapproved1996)e1AnAmericanNationalStandardStandardSpecificationforAluminumSilicatePigments(Anhydrous)1ThisstandardisissuedunderthefixeddesignationD3619;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.e1NOTE—KeywordswereaddededitoriallyinMay1996.1.Scope1.1Thisspecificationcoversthewhitepigmentsthatconsistsubstantiallyofanhydrous(calcined)naturalaluminumsili-cates2(ofthe1+1layertype)andarerestrictedtothosemineralswhichconformtothechemicalcompositionallimitsprescribedhereinandwhichcanbesuitablyprocessedtowhatisknownaspaintpigmentquality.2.ReferencedDocuments2.1ASTMStandards:D281TestMethodforOilAbsorptionofPigmentsbySpatulaRub-Out3D718TestMethodsforAnalysisofAluminumSilicatePigment4D1203TestMethodsforVolatileLossfromPlasticsUsingActivatedCarbonMethods5D1483TestMethodforOilAbsorptionofPigmentsbyGardner-ColemanMethod3D2448TestMethodforWater-SolubleSaltsinPigmentsbyMeasuringtheSpecificResistanceoftheLeachateofthePigment4D3360TestMethodforParticleSizeDistributionbyHy-drometeroftheCommonWhiteExtenderPigments4E70TestMethodforpHofAqueousSolutionswiththeGlassElectrode63.CompositionandProperties3.1Preparation—Thepigmentshallbemadebygrinding,milling,washing,purifying,orotherwiseprocessing,naturalhydrousaluminumsilicatesfollowedbyheattreatment(calci-nation)sufficienttoreducetheresidualpercentlossonignitiontoamaximumof0.5%andotherwiseconformingtothecompositionrequirements(weightpercent)giveninTable1.3.2pH—ThepHofawaterslurryofthepigmentshallbewithinarangefrom4.5to5.5unlessotherwiseagreeduponbetweenthepurchaserandtheseller.3.3Water-SolubleMatter—Thewater-solublemattershallbenotmorethan0.60%.3.4Wet-SieveResidue—Thepigmentshallcontainnomorethan0.02%wet-sieveresidueretainedona45µm(No.325)sieve(gritorcoarseparticles)exceptasmaybeagreeduponbetweenthepu...