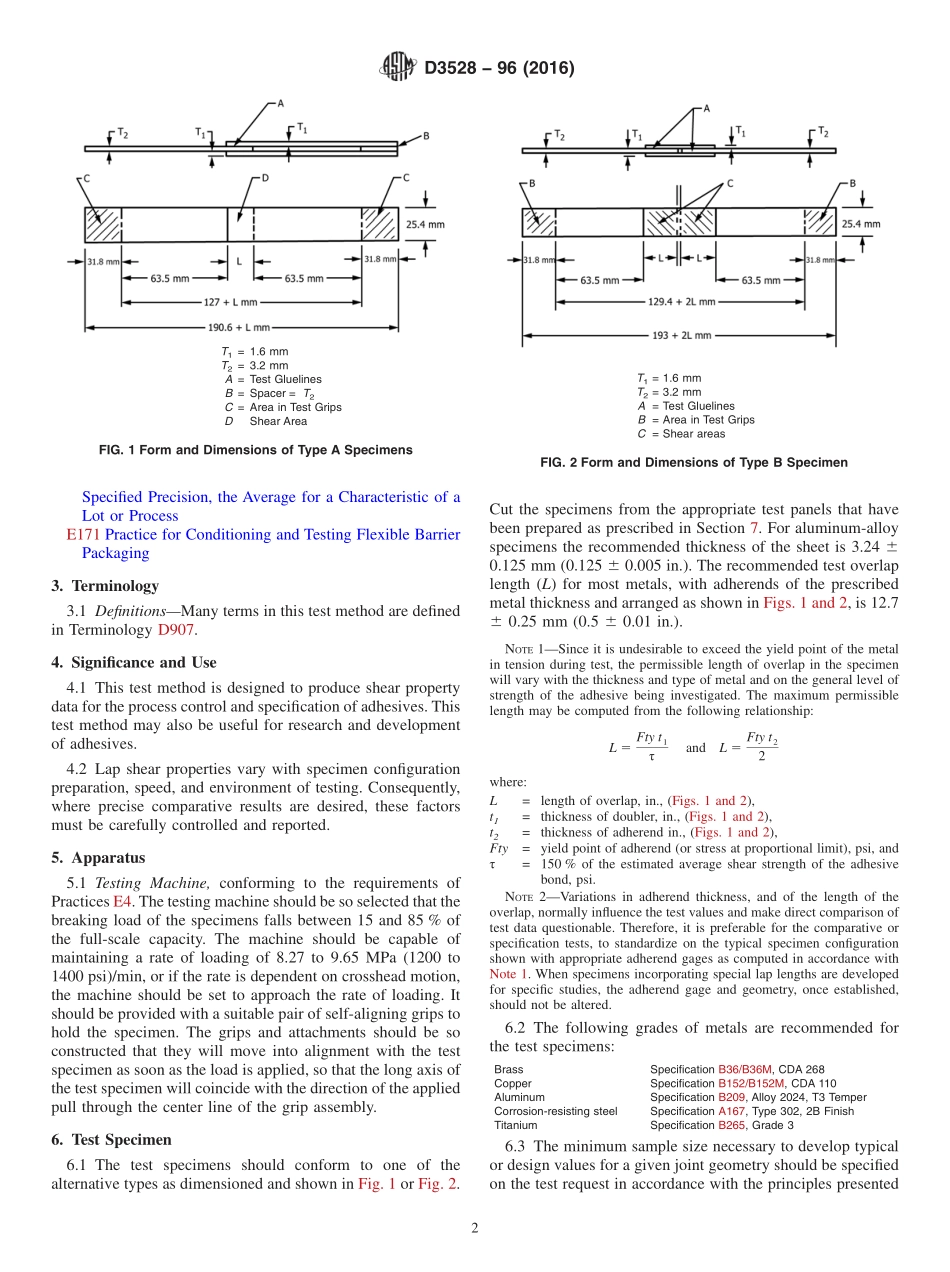

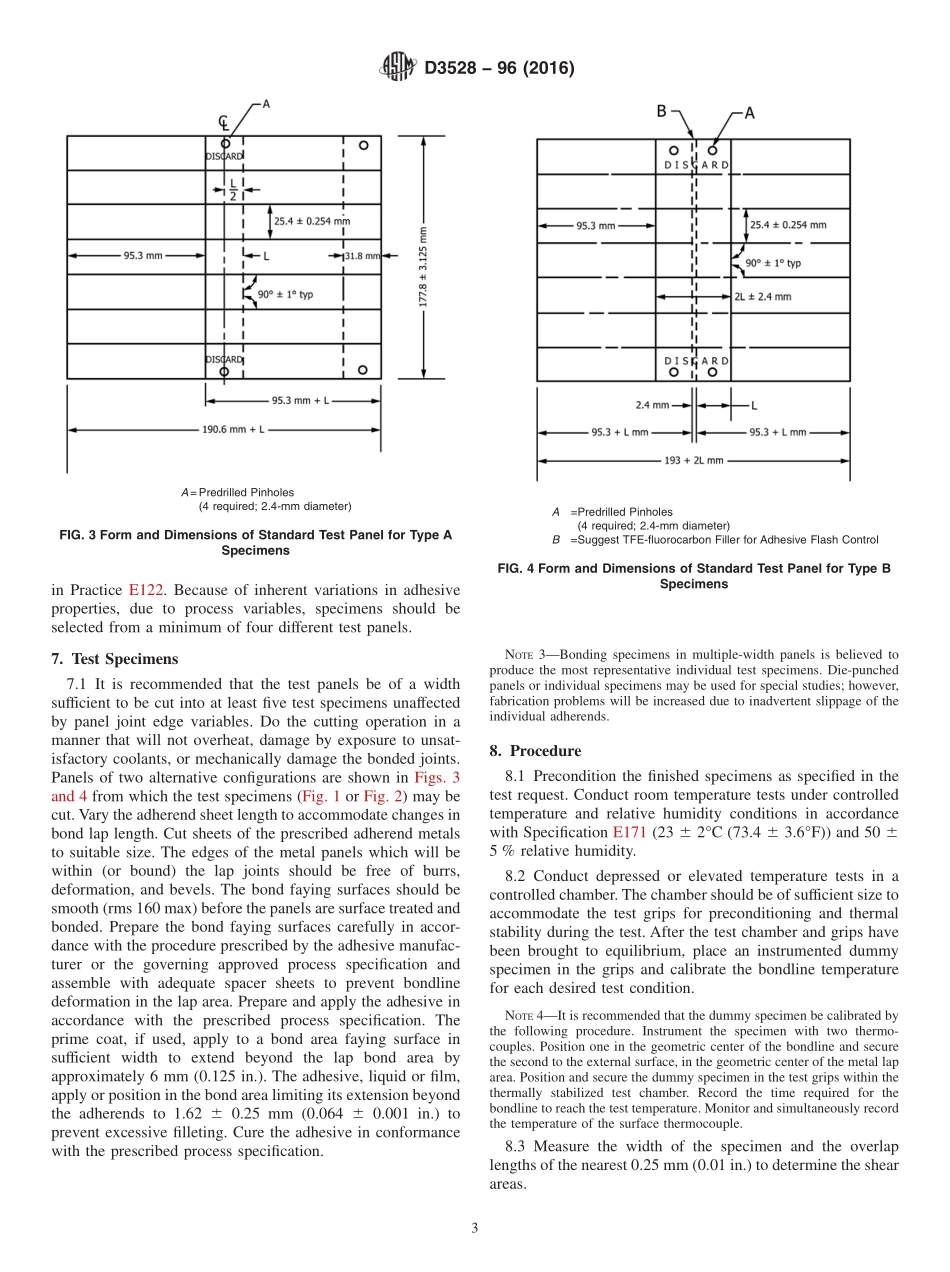

Designation:D3528−96(Reapproved2016)StandardTestMethodforStrengthPropertiesofDoubleLapShearAdhesiveJointsbyTensionLoading1ThisstandardisissuedunderthefixeddesignationD3528;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.INTRODUCTIONTheaccuracyoftheresultsofstrengthtestsofadhesivebondswilldependontheconditionsunderwhichthebondingprocessiscarriedout.Unlessotherwiseagreeduponbetweenthemanufacturerandthepurchaser,thebondingconditionsshouldbeprescribedbythemanufactureroftheadhesive.Inordertoensurethatcompleteinformationisavailabletotheindividualconductingthetests,themanufactureroftheadhesiveshouldfurnishnumericalvaluesandotherspecificinformationforeachofthefollowingvariables:(1)Surfacepreparation(2)Mixingdirections(3)Adhesiveapplication(4)Assemblyconditions(5)Curingconditions(6)TestingconditionsArangemaybeprescribedforanyvariablebythemanufactureroftheadhesiveifitcanbeassumedbythetestoperatorthatanyarbitrarilychosenvaluewithinsucharangeoranycombinationofsuchvaluesforseveralvariableswillbeacceptabletoboththemanufacturerandthepurchaseroftheadhesive.1.Scope1.1Thistestmethodcoversthedeterminationofthetensileshearstrengthsofadhesivesforbondingmetalswhentestedinanessentiallypeel-freestandardspecimenthatdevelopsadhe-sivestressdistributionrepresentativeofthatdevelopedinatypicallow-peelproduction-typestructuraljoint.Therepro-ducibilityofthestrengthsachievedaredirectlyrelatedtoconformancewithspecifiedconditionsofpreparationandtesting.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortous...