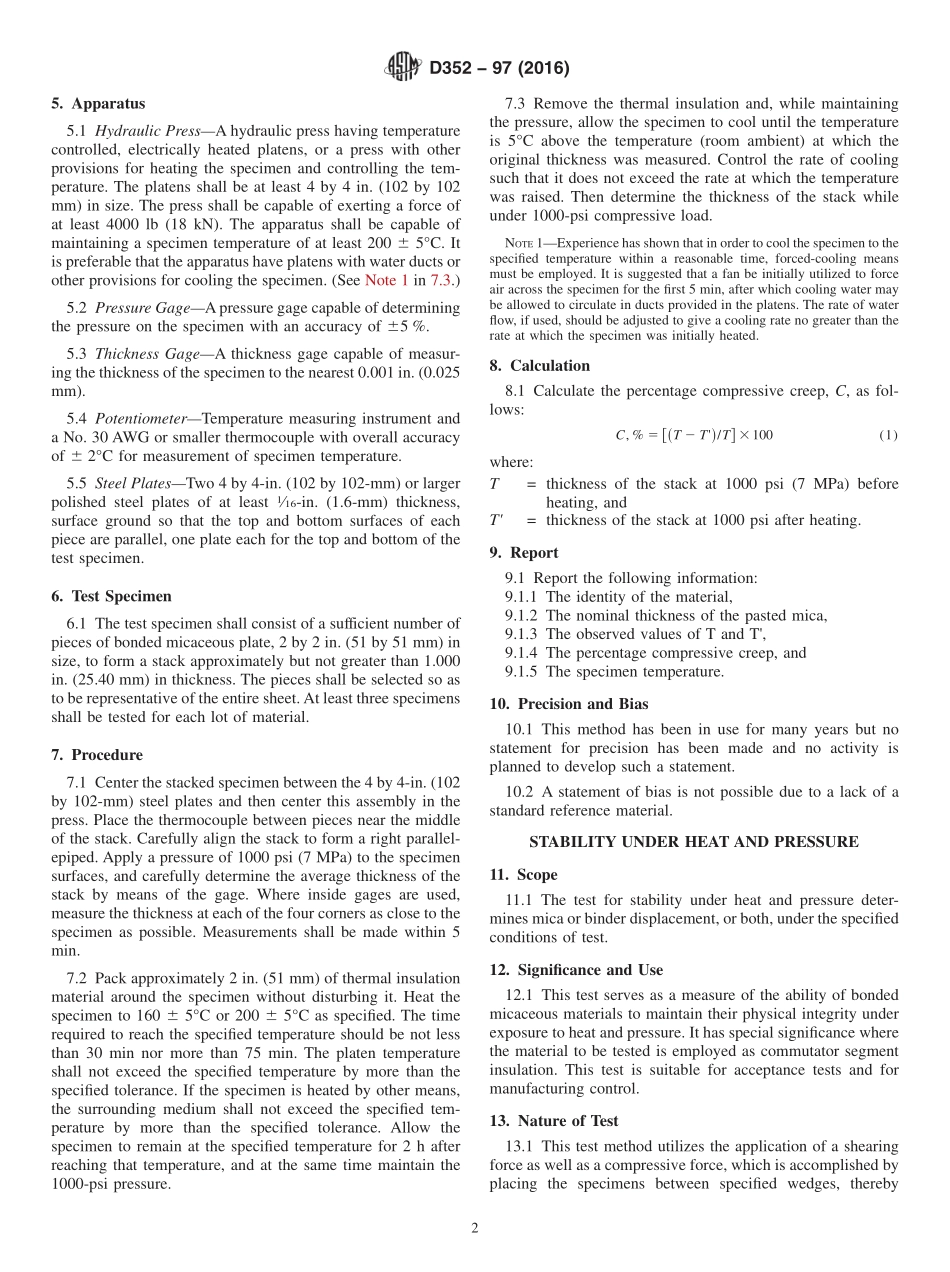

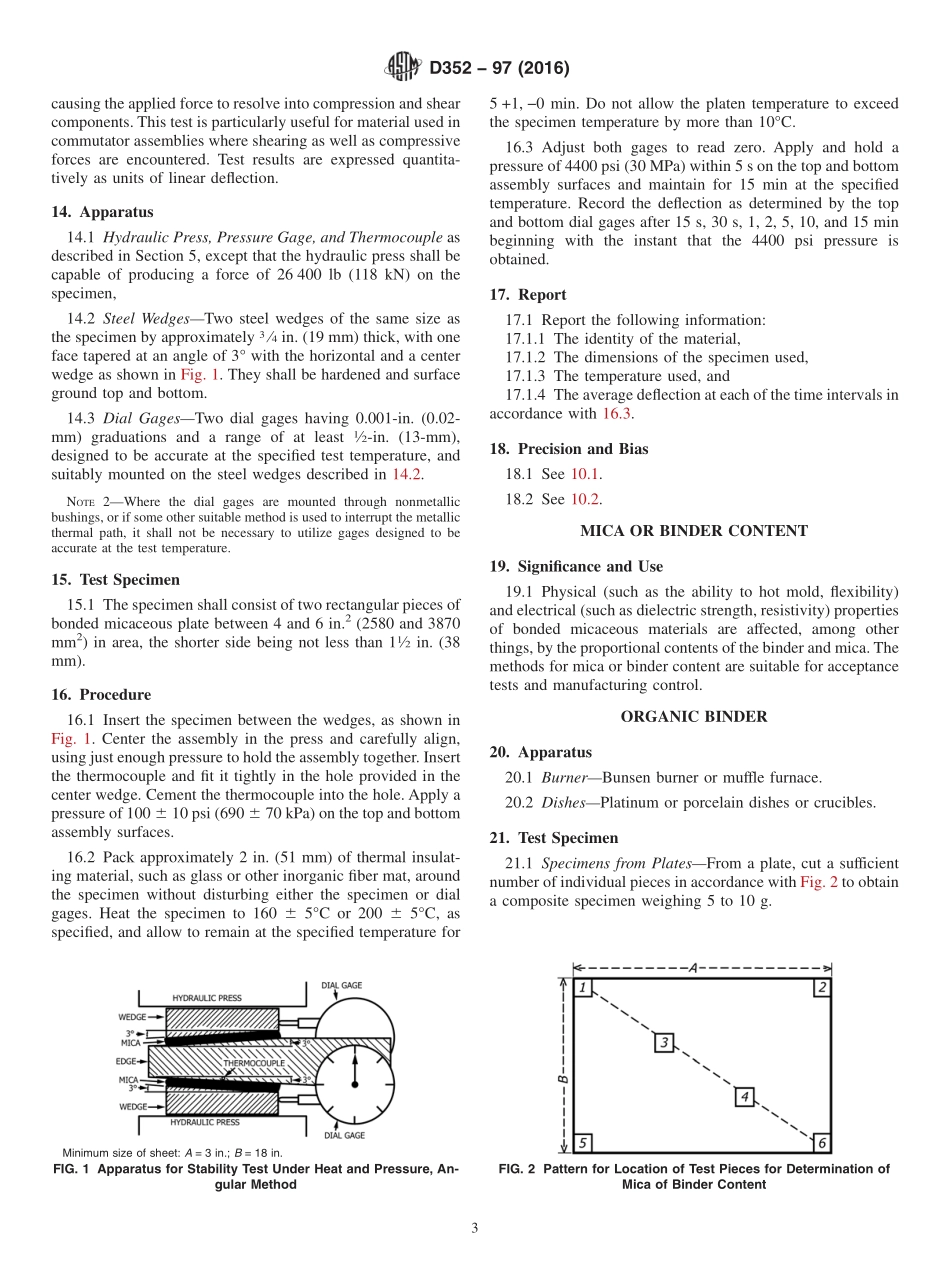

Designation:D352−97(Reapproved2016)StandardTestMethodsforPastedMicaUsedinElectricalInsulation1ThisstandardisissuedunderthefixeddesignationD352;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscoverthetestingofbondedmicasplittingsandbondedmicapapertobeusedforcommutatorinsulation,hotmolding,heaterplates,andothersimilarinsu-latingpurposes.1.2Thesetestmethodsappearinthefollowingsections:TestSectionsCompressiveCreep4–10DielectricStrength38–41MicaorBinderContent19MoldingTest31–36OrganicBinder20–24Resistivity42–46SiliconeBinder25–30StabilityUnderHeatandPressure11–181.3Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.See40.1and45.1forspecifichazardstatements.2.ReferencedDocuments2.1ASTMStandards:2D149TestMethodforDielectricBreakdownVoltageandDielectricStrengthofSolidElectricalInsulatingMaterialsatCommercialPowerFrequenciesD257TestMethodsforDCResistanceorConductanceofInsulatingMaterialsD1711TerminologyRelatingtoElectricalInsulation3.Terminology3.1Definitions:3.1.1Fordefinitionsoftermsrelatingtoelectricalinsulation,refertoTerminologyD1711.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1bindercontent,n,(ofpastedmica)—thepercentbyweightofbinderrelativetotheoriginalweightofaspecimenasdeterminedbyproceduresspecifiedherein.3.2.1.1Discussion—Bindercontentincludesanyresidualsolvent.Pastedmicamaterialsnotfullycured(suchasmoldingandflexibleplates)maycontainappreciablequantit...