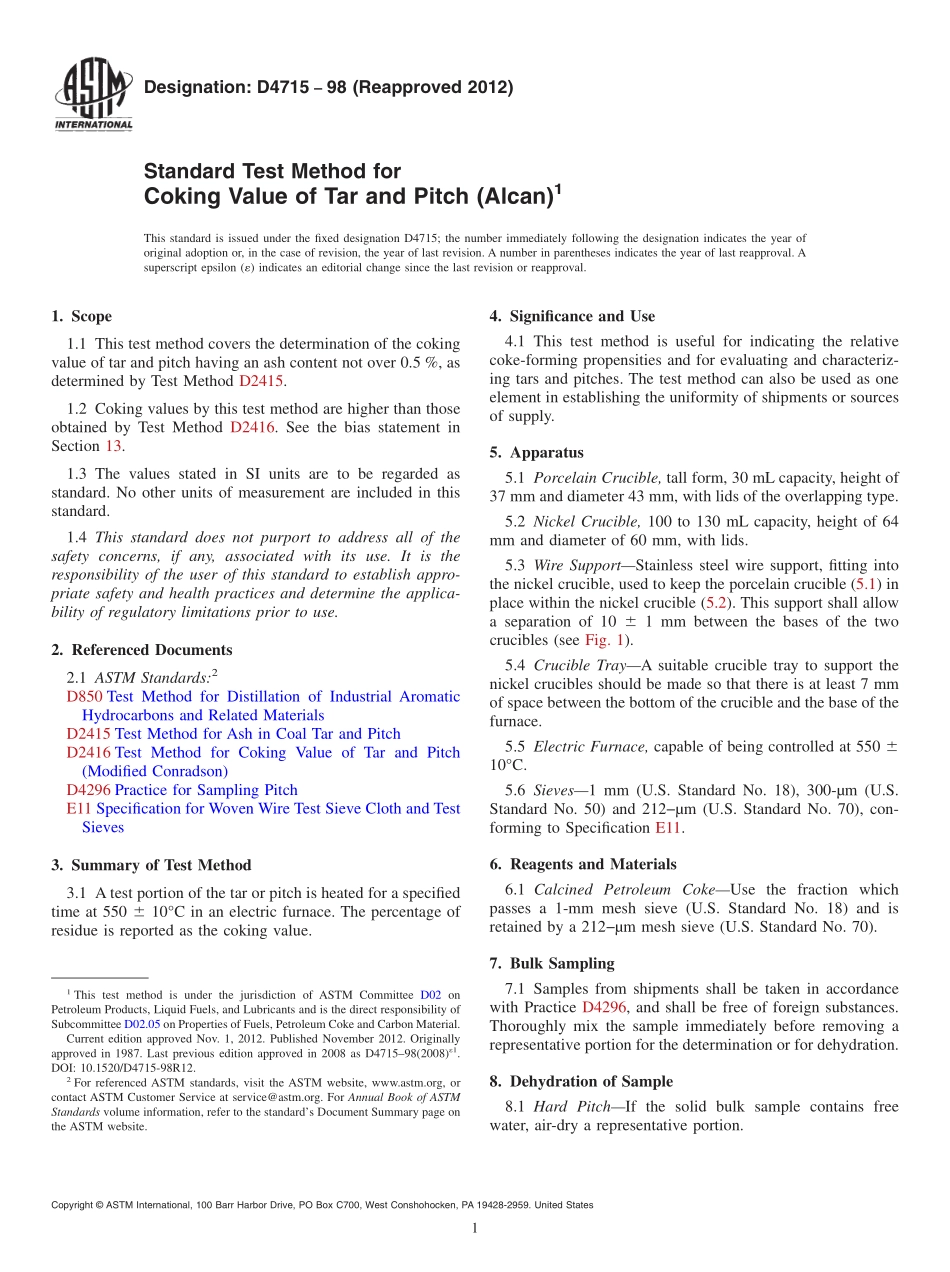

Designation:D4715−98(Reapproved2012)StandardTestMethodforCokingValueofTarandPitch(Alcan)1ThisstandardisissuedunderthefixeddesignationD4715;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthecokingvalueoftarandpitchhavinganashcontentnotover0.5%,asdeterminedbyTestMethodD2415.1.2CokingvaluesbythistestmethodarehigherthanthoseobtainedbyTestMethodD2416.SeethebiasstatementinSection13.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D850TestMethodforDistillationofIndustrialAromaticHydrocarbonsandRelatedMaterialsD2415TestMethodforAshinCoalTarandPitchD2416TestMethodforCokingValueofTarandPitch(ModifiedConradson)D4296PracticeforSamplingPitchE11SpecificationforWovenWireTestSieveClothandTestSieves3.SummaryofTestMethod3.1Atestportionofthetarorpitchisheatedforaspecifiedtimeat550610°Cinanelectricfurnace.Thepercentageofresidueisreportedasthecokingvalue.4.SignificanceandUse4.1Thistestmethodisusefulforindicatingtherelativecoke-formingpropensitiesandforevaluatingandcharacteriz-ingtarsandpitches.Thetestmethodcanalsobeusedasoneelementinestablishingtheuniformityofshipmentsorsourcesofsupply.5.Apparatus5.1PorcelainCrucible,tallform,30mLcapacity,heightof37mmanddiameter43mm,withlidsoftheoverlappingtype.5.2NickelCrucible,100to130mLcapacity,heightof64mmanddiameterof60mm,withlids.5.3WireSupport—Stainlesssteelwiresupport,fittingintothenickelcrucible,usedtokeeptheporcelaincrucible(5.1)inplacewithinthenickelcruc...