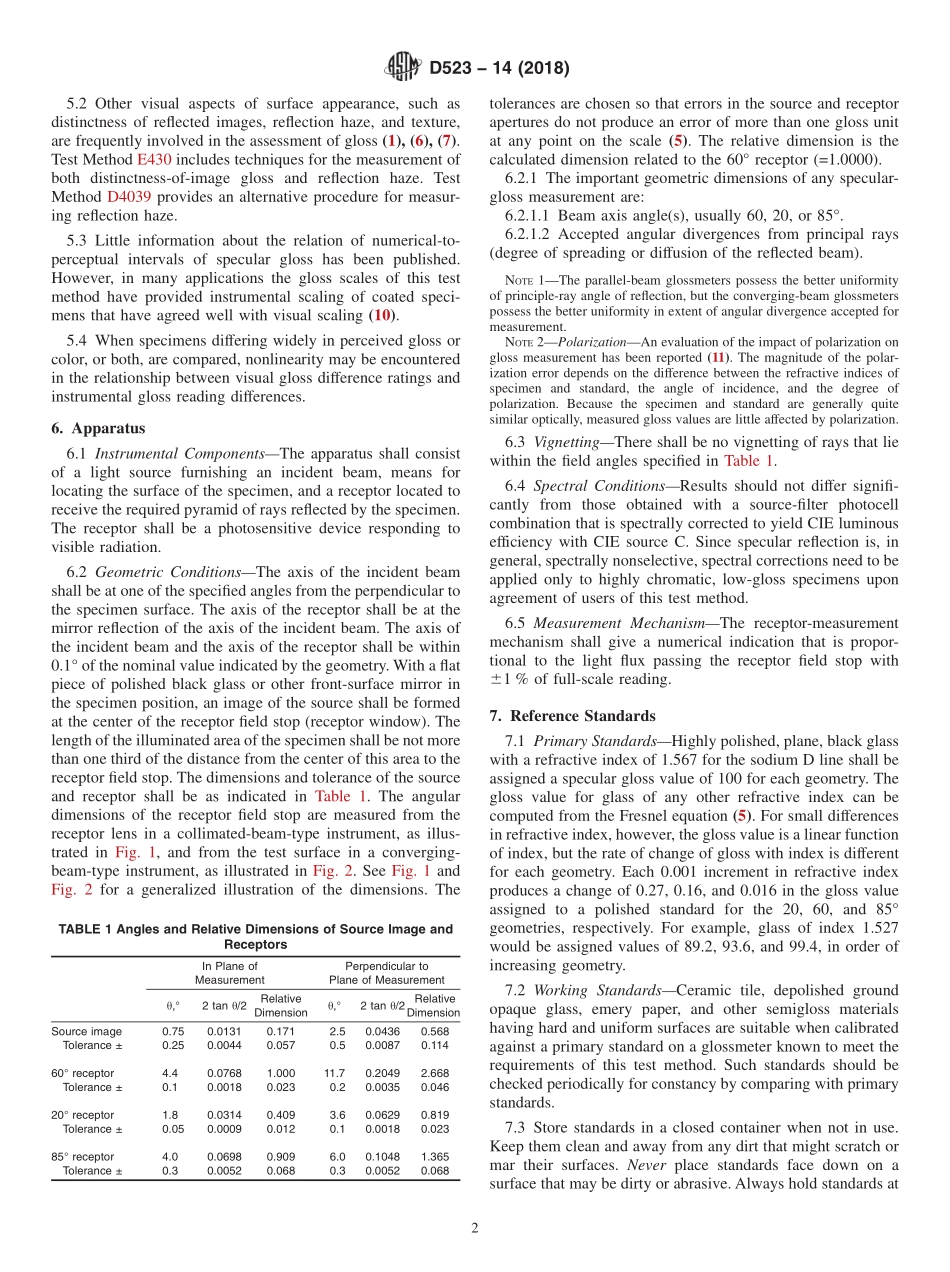

Designation:D523−14(Reapproved2018)StandardTestMethodforSpecularGloss1ThisstandardisissuedunderthefixeddesignationD523;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversthemeasurementofthespecularglossofnonmetallicspecimensforglossmetergeometriesof60,20,and85°(1-7).21.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:3D823PracticesforProducingFilmsofUniformThicknessofPaint,CoatingsandRelatedProductsonTestPanelsD3964PracticeforSelectionofCoatingSpecimensforAppearanceMeasurementsD3980PracticeforInterlaboratoryTestingofPaintandRelatedMaterials(Withdrawn1998)4D4039TestMethodforReflectionHazeofHigh-GlossSurfacesE97MethodofTestforDirectionalReflectanceFactor,45-Deg0-Deg,ofOpaqueSpecimensbyBroad-BandFilterReflectometry(Withdrawn1991)4E430TestMethodsforMeasurementofGlossofHigh-GlossSurfacesbyAbridgedGoniophotometry3.Terminology3.1Definitions:3.1.1relativeluminousreflectancefactor,n—theratiooftheluminousfluxreflectedfromaspecimentotheluminousfluxreflectedfromastandard...