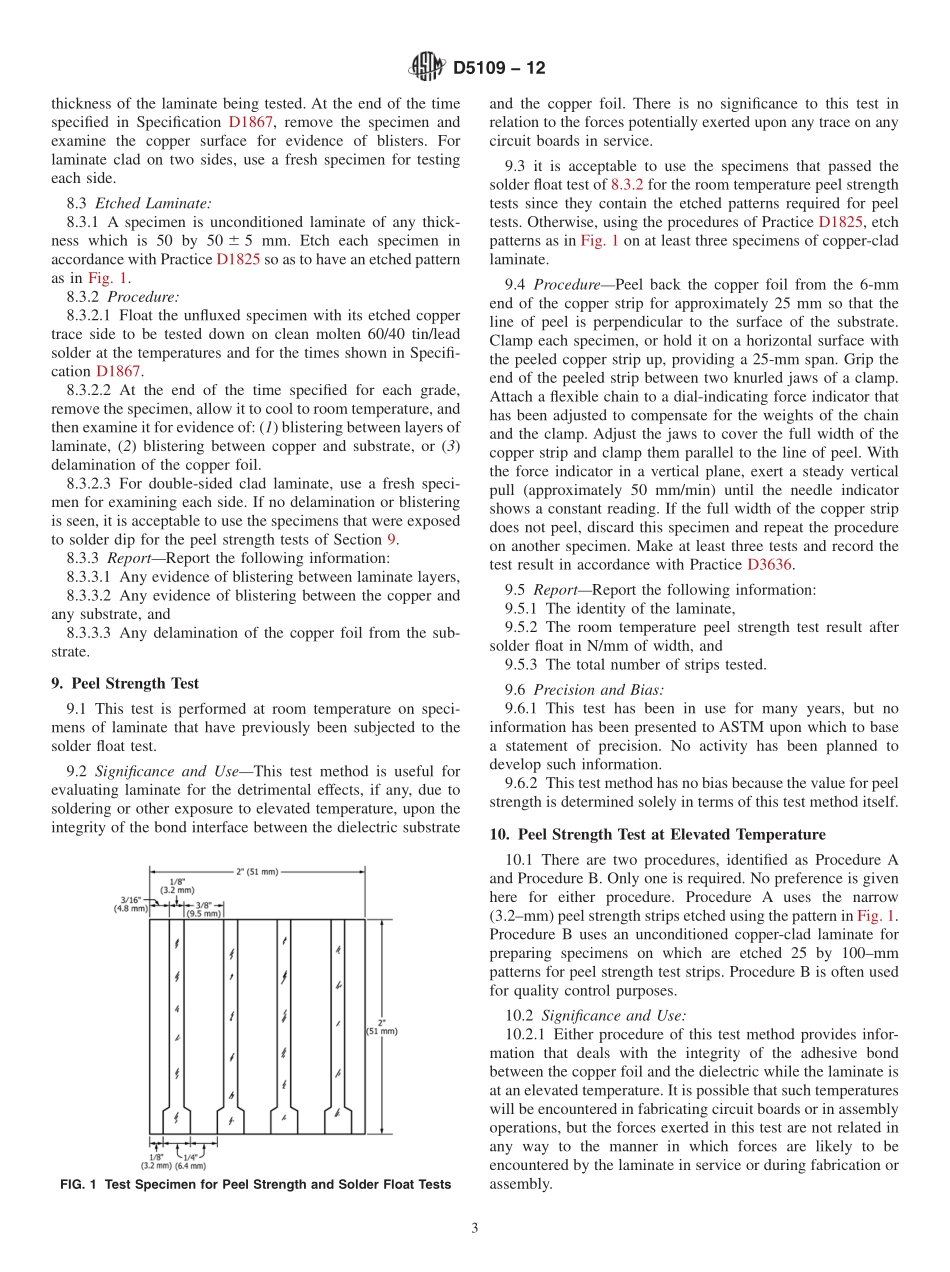

Designation:D5109−12StandardTestMethodsforCopper-CladThermosettingLaminatesforPrintedWiringBoards1ThisstandardisissuedunderthefixeddesignationD5109;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thesetestmethodscovertheproceduresfortestingcopper-cladlaminatesproducedfromfiber-reinforced,thermo-settingpolymericmaterialsintendedforfabricationofprintedwiringboards.1.2Theproceduresappearinthefollowingsections:ProcedureSectionReferencedDocuments2Conditioning4DielectricBreakdownVoltageParalleltoLaminations13DimensionalInstability19DissipationFactor14FlammabilityRatingTest16FlexuralStrength,FlatwiseatElevatedTemperature15FlexuralStrength,FlatwiseatRoomTemperature15OvenBlisterTest17PeelStrengthTestatElevatedTemperature10PeelStrengthTestatRoomTemperature9Permittivity14PinHolesinCopperSurface20PurityofCopper5ScratchesinCopperSurface21SolderFloatTest8SolventResistance7SurfaceResistivity11VolumeResistivity11Terminology3Thickness&ThicknessVariation18WarporTwist6WaterAbsorption121.3Metricunitsarethepreferredunitsforthesetestmethods.Inch-poundunits,whereshown,arepresentedforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Forspecifichazardstatements,see7.2.1,8.1,and11.3.1.2.ReferencedDocuments2.1ASTMStandards:2D150TestMethodsforACLossCharacteristicsandPermit-tivity(DielectricConstant)ofSolidElectricalInsulationD229TestMethodsforRigidSheetandPlateMaterialsUsedforElectricalInsulationD257TestMethodsforDCResistanceorConductanceofInsulatingMaterialsD374TestMethodsforThicknessofSolidElectricalInsu-lation(Withdrawn2013)3D618PracticeforConditioningPlasticsforTest...