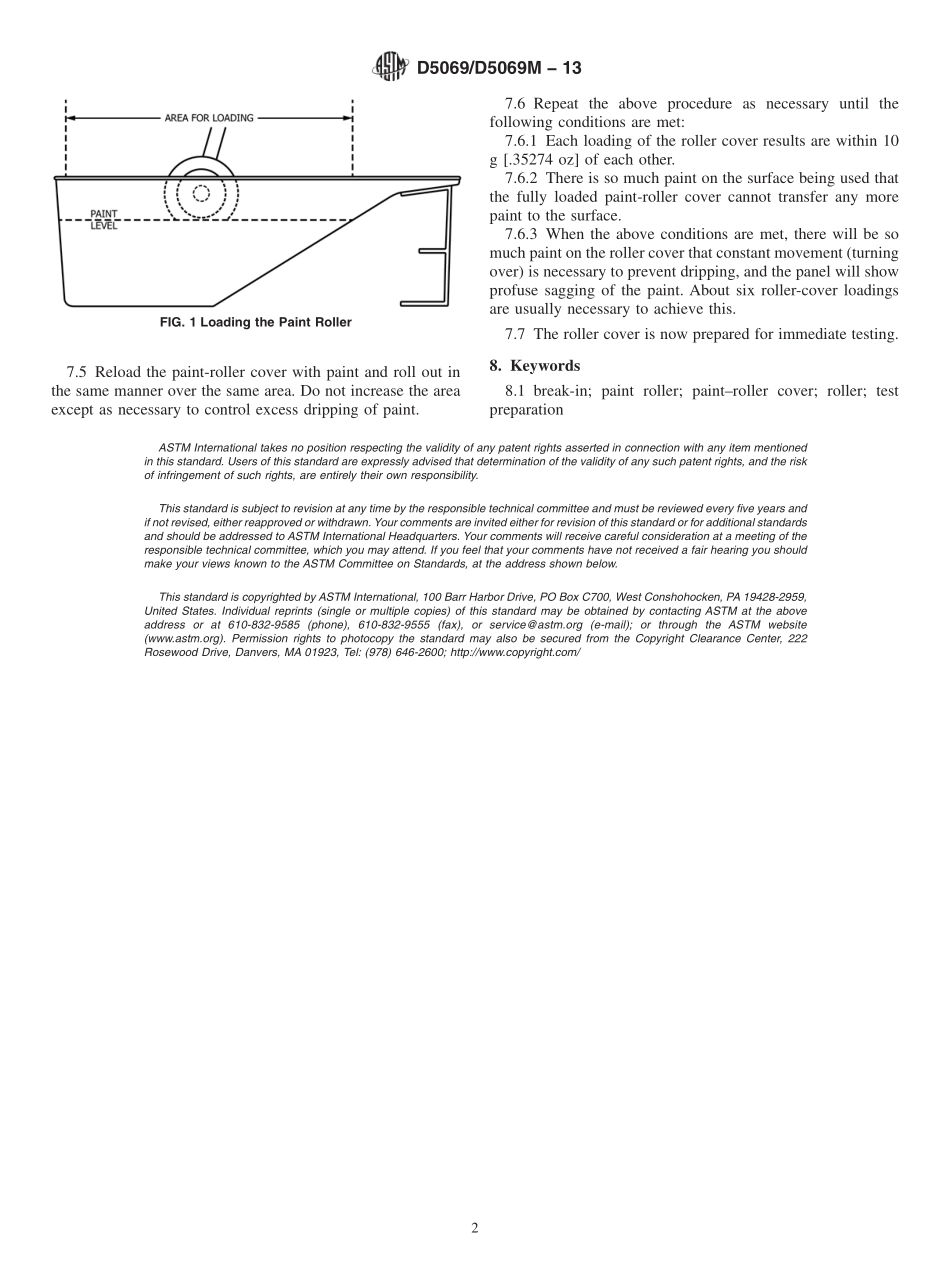

Designation:D5069/D5069M−13StandardPracticeforPreparationofPaint-RollerCoversforEvaluationofArchitecturalCoatings1ThisstandardisissuedunderthefixeddesignationD5069/D5069M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversthepreparationorbreaking-inofpaint-rollercoversforevaluation.1.2Thispracticeisapplicabletopaint-rollercovershavingnaplengthsupto13mm[1⁄2in.].Longerpilerollerscanbeadapted.1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.4Thisstandarddoesnotpurporttoaddressthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D3924SpecificationforEnvironmentforConditioningandTestingPaint,Varnish,Lacquer,andRelatedMaterials3.SummaryofPractice3.1Usingthepaintchosenfortheevaluation,thepaint-rollercovertobetestedisrepeatedlyandgenerouslyloadedwithpaintandpaintedoutoverthesameareauntilitissaturatedwithpaint,thatis,thepaint-rollercovercannotpickupanymorepaint,norapplyanymorepainttotheareabeingusedforbreak-in.4.SignificanceandUse4.1Untilapaint-rollercoverissaturatedwithpaint,onlypartofthepaintloadedontothepaint-rollercovercanbetransferredtoasurfacebeingpainted.Theremainderofthepaintisabsorbedintothefabricofthepaint-rollercover.Theamountofpaintabsorbedbyapaint-rollercoverisinverselyproportionaltotheamountalreadypresentwithinthepaint-rollercover.Bysaturatingthepaint-rollercoverbeforetesting,quantitativeinaccuraciesoftheamountofpaintdeliveredtoasu...