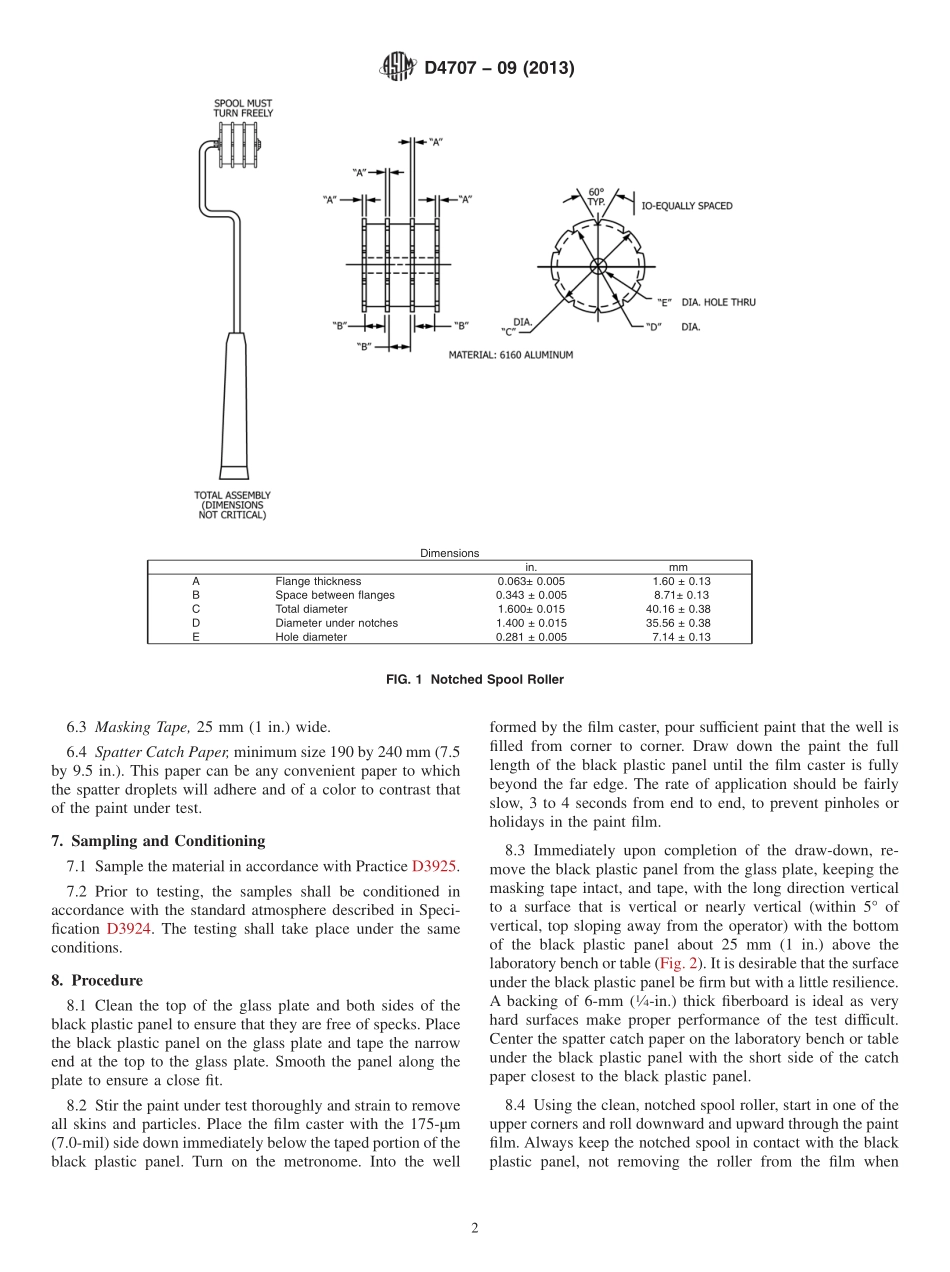

Designation:D4707−09(Reapproved2013)StandardTestMethodforMeasuringPaintSpatterResistanceDuringRollerApplication1ThisstandardisissuedunderthefixeddesignationD4707;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftheten-dencyofapainttospatterwhenappliedwithapaintrollertoasubstrate.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D3924SpecificationforEnvironmentforConditioningandTestingPaint,Varnish,Lacquer,andRelatedMaterialsD3925PracticeforSamplingLiquidPaintsandRelatedPigmentedCoatings2.2OtherDocument:PictorialStandardsofPaintRollerSpatter33.SummaryofTestMethod3.1Thetestpaintisappliedtoablackplasticpanelbydraw-down.Thecoatedplasticpanelisimmediatelymountedonanessentiallyverticalsurfaceaboveasheetofpaperusedtocatchanyspatter.Aspeciallydesignednotchedspoolroller(see5.1)isrolledthroughthefilmfollowingadefinedprocedure,tendingtogeneratespatter.Anyspatterfallsuponthespattercatchpaperand,afterdrying,isratedagainstthepictorialstandards.4.SignificanceandUse4.1Paintspattergeneratedbyrollerapplicationisdepen-dentonthepropertiesofboththepaintbeingappliedandthepaintrollercoverusedfortheapplication.Toeliminatetheinfluenceofthepaintrollercoverasavariable,andthusrestrictthespatter-inducingvariabletothepaintundertestonly,thepaintrollercoverisreplacedbyastandardnotchedspoolrollertogeneratespatterbyamechanismthatsimulatesthatofapaint-applyingrollercover.4.2Althoughmostofthedevelopmentworktoestablishthistestmethodwasundertakenusinglatexpaints,sufficientworkwasalsodonetoshowitsapplicabilitytosolvent-red...