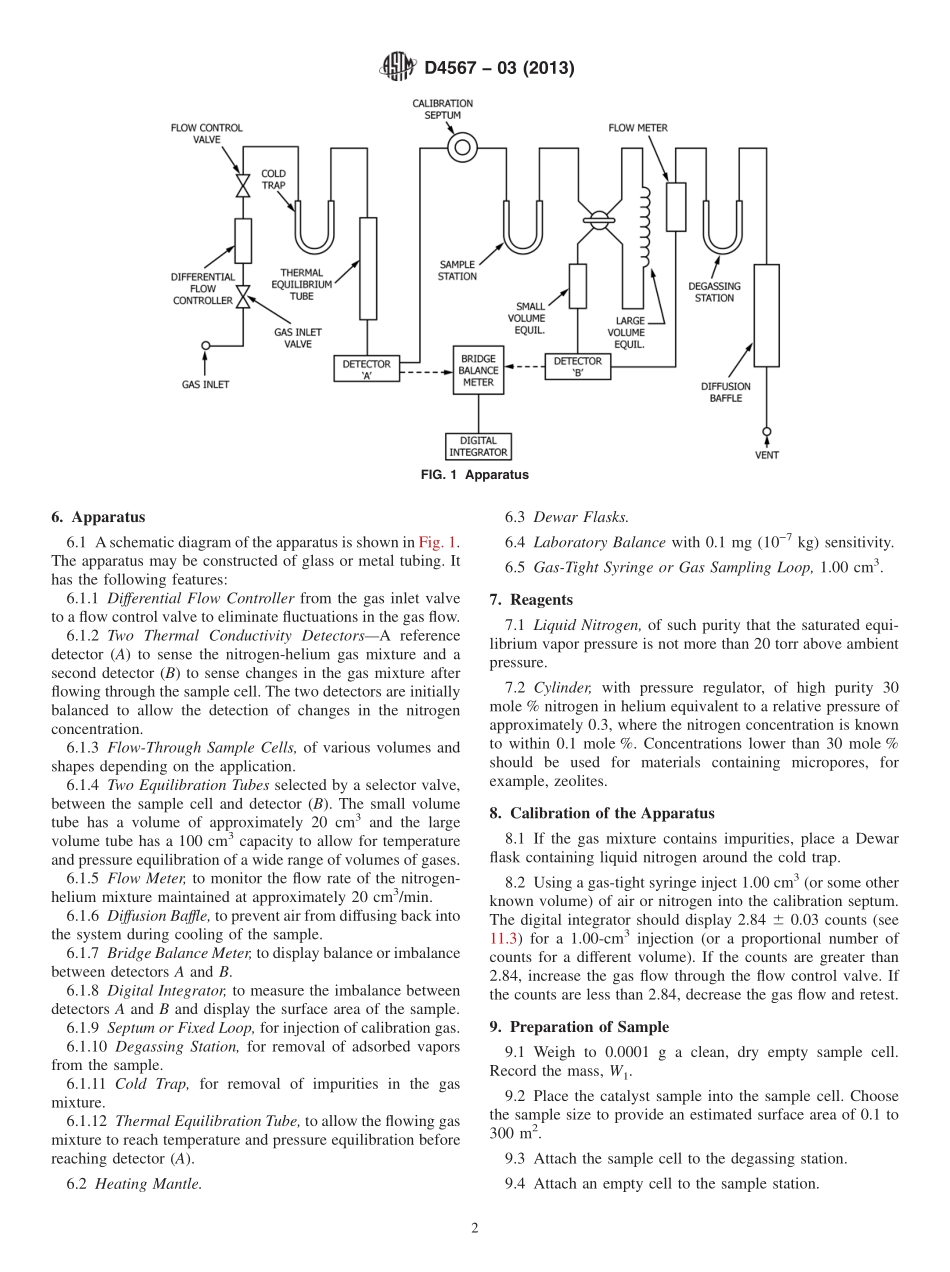

Designation:D4567−03(Reapproved2013)StandardTestMethodforSingle-PointDeterminationofSpecificSurfaceAreaofCatalystsandCatalystCarriersUsingNitrogenAdsorptionbyContinuousFlowMethod1ThisstandardisissuedunderthefixeddesignationD4567;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthesingle-pointdeterminationofthesurfaceareaofcatalystsandcatalystcarriersthatexhibitTypeIIorTypeIVnitrogenadsorptionisothermsusinganitrogen-heliumflowinggasmixture.Thistestmethodisapplicableforthedeterminationoftotalsurfaceareasfrom0.1to300m2,whererapidsurfaceareadeterminationsaredesired.1.2Becausethesingle-pointmethodusesanapproximationoftheBETequation,themultipointBETmethod(TestMethodD3663)ispreferredtothesingle-pointmethod.NOTE1—Thisisparticularlytruewhentestingmicroporousmaterials.1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityofwhoeverusesthisstandardtoconsultandestablishappropriatesafetyandhealthpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D3663TestMethodforSurfaceAreaofCatalystsandCatalystCarriersD3766TerminologyRelatingtoCatalystsandCatalysisE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE456TerminologyRelatingtoQualityandStatisticsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions—SeeTerminologyD3766.3.2Symbols:Acs=cross-sectionalareaofnitrogen,16.2×10−20m2.CI=integratorcounts.CITa=integratorcountscorrectedforambienttemperature.CIPa=integratorcountscorrectedforambientpressure.N=Avogadro’snumber,6.02×1023,molecules/mole.P=partialpressureofni...