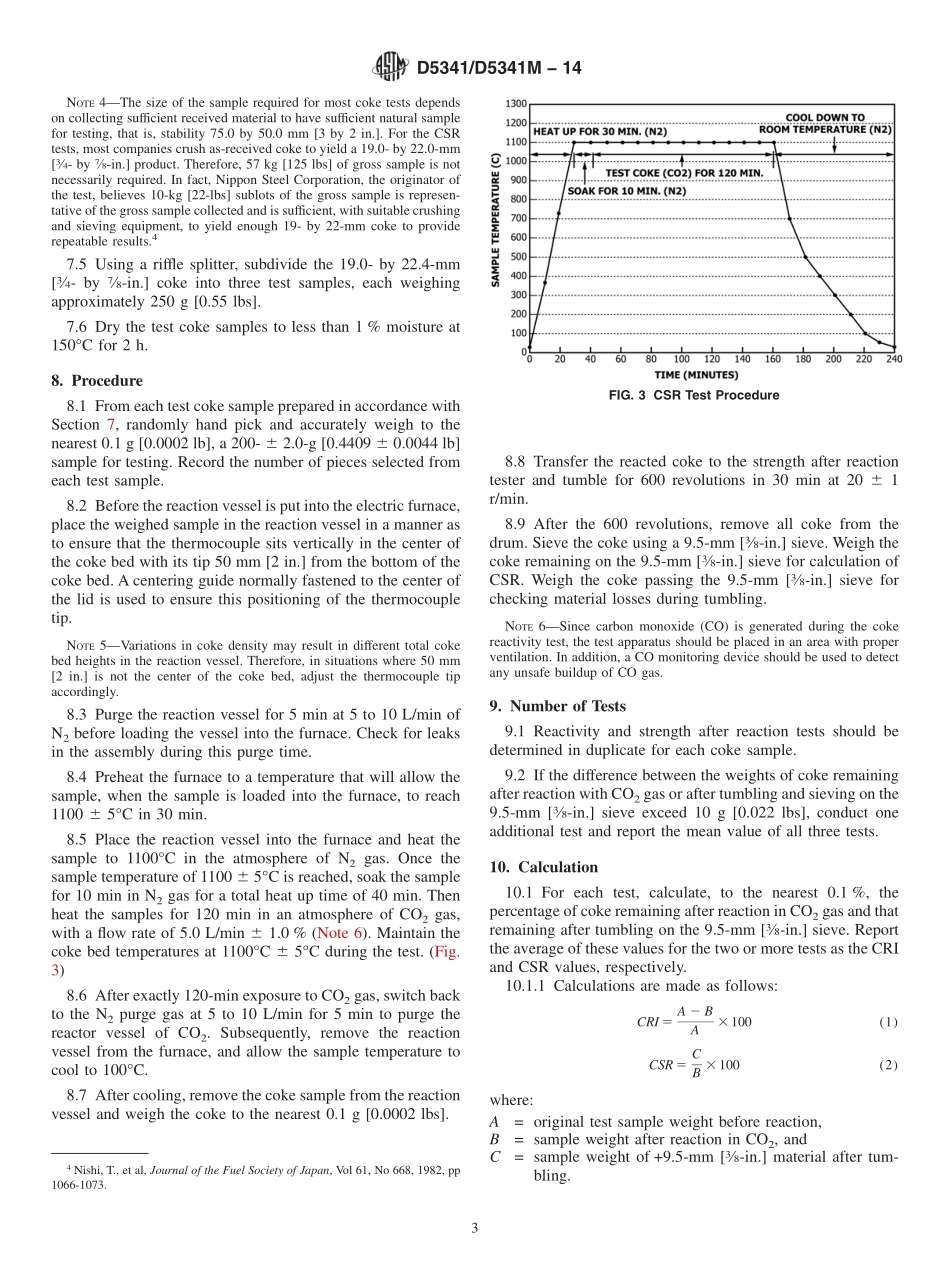

Designation:D5341/D5341M−14StandardTestMethodforMeasuringCokeReactivityIndex(CRI)andCokeStrengthAfterReaction(CSR)1ThisstandardisissuedunderthefixeddesignationD5341/D5341M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethod,patternedaftertheNipponSteeltestprocedure,describestheequipmentandtechniquesusedfordetermininglumpcokereactivityincarbondioxide(CO2)gasatelevatedtemperaturesanditsstrengthafterreactioninCO2gasbytumblinginacylindricalchamberreferredtoasanI-tester.1.2ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D346PracticeforCollectionandPreparationofCokeSamplesforLaboratoryAnalysisE11SpecificationforWovenWireTestSieveClothandTestSievesE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod2.2BritishCarbonizationResearchAssociationReport:CarbonizationResearchReport91,“TheEvaluationoftheNipponSteelCorporationReactivityandPost-Reaction-StrengthTestforCoke.”33.SummaryofTestMethod3.1AsampleofdriedcokeofdesignatedoriginandsizeisreactedwithCO2gasinaretortataspecifiedelevatedtemperatureforaspecifiedlengthoftime.Twoindices,cokereactivityindex(CRI)andcokestrengthafterreaction(CSR),aredeterminedusingthereactedcokeresidue.TheweightlossafterreactiondeterminestheCRI.Theweightretainedaftersievingthetumbledreactedcokeinadesignate...