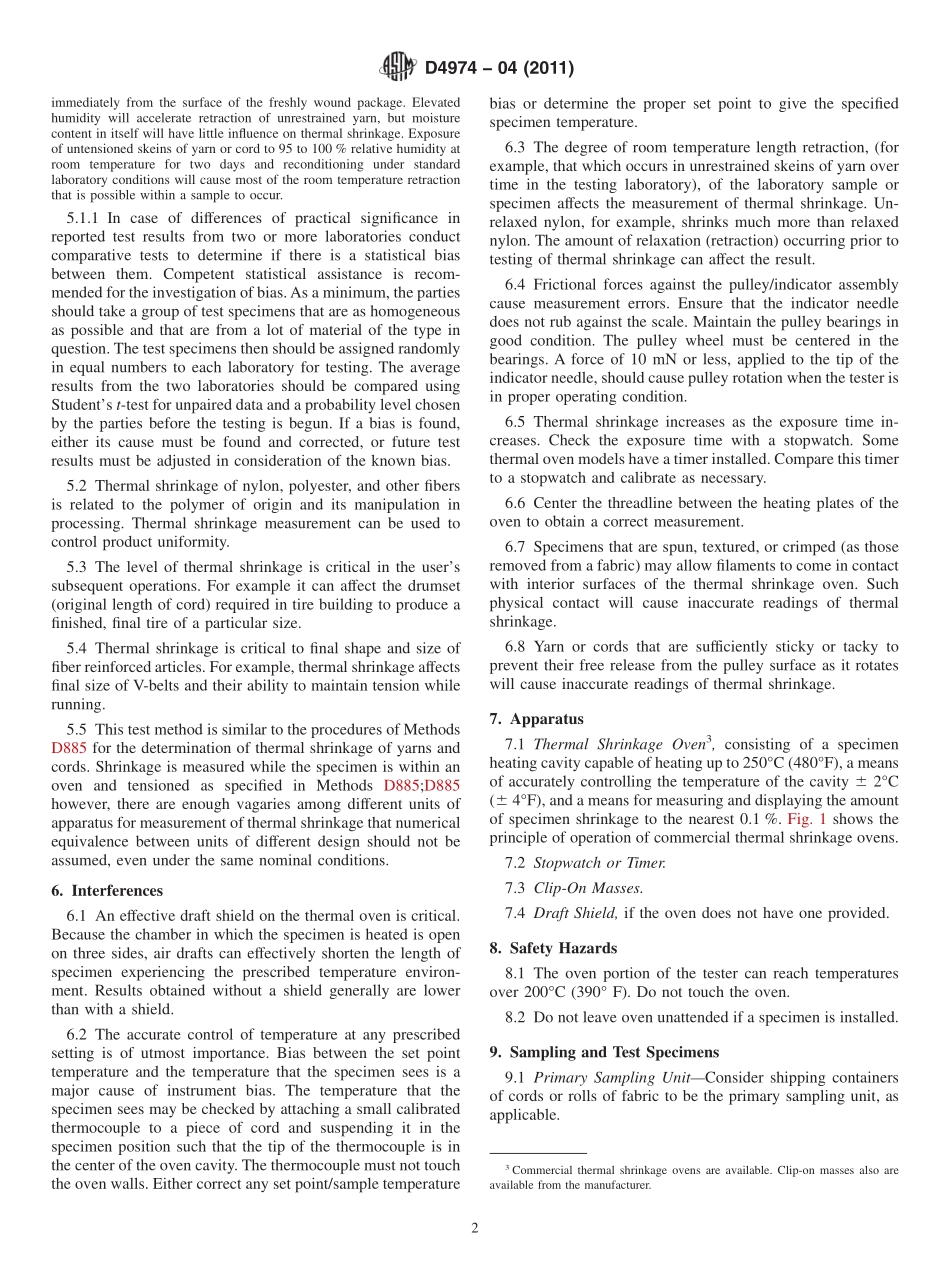

Designation:D4974−04(Reapproved2011)StandardTestMethodforHotAirThermalShrinkageofYarnandCordUsingaThermalShrinkageOven1ThisstandardisissuedunderthefixeddesignationD4974;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthemeasurementofshrinkageofyarnsandcordswhenexposedinathermalshrinkageoven.1.2Thistestmethodisapplicabletoyarnsandcordsmadeofnylon,polyester,andotherpolymersnotdetrimentallyaffectedbythetemperatureusedandwithlineardensitiesintherangefrom20to700tex(180to6300denier).1.2.1Yarnsorcordsfortestingmaybetakenfromyarnorcordpackagesorfromfabrics.1.3ThistestmethodshowsvaluesinbothSIandinch-poundunits.SIisthetechnicallycorrectnameforthesystemofunitsknownastheInternationalSystemofUnits.Inch-poundunitsisthetechnicallycorrectnameforthecustomaryunitsusedintheUnitedStates.Thevaluesstatedineitheracceptablemetricunitsorotherunitsshallberegardedseparatelyasstandard.Thevaluesexpressedineachsystemmaynotbeexactequivalents;therefore,eachsystemmustbeusedindependentlyofeachother,withoutcombiningvaluesinanyway.RefereedecisionsaretouseSIunits.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.SpecifichazardstatementsaregiveninSection8.2.ReferencedDocuments2.1ASTMStandards:2D123TerminologyRelatingtoTextilesD885TestMethodsforTireCords,TireCordFabrics,andIndustrialFilamentYarnsMadefromManufacturedOrganic-BaseFibersD1776PracticeforConditioningandTestingTextilesD6477TerminologyRelatingtoTireCord,BeadWire,HoseReinforcingWire,andFabrics3.Terminology3.1Definitions:3.2Fordefinitionsoftermsrelatingtotirecord,beadwire,hosewire,andtirecordfabrics,refertoTerminologyD6...